Contact sh-guided-wave magnetostrictive transducer

一种水平切变、磁致伸缩的技术,应用在磁致伸缩器件、磁致伸缩传感器、磁致伸缩器件的零部件等方向,能够解决难以控制剩余磁化强度等问题,达到高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

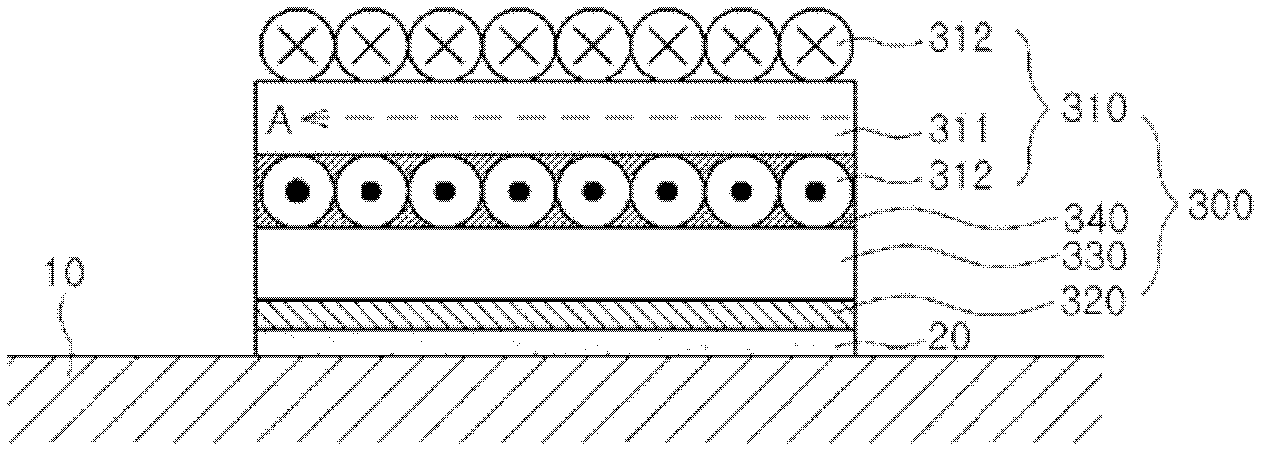

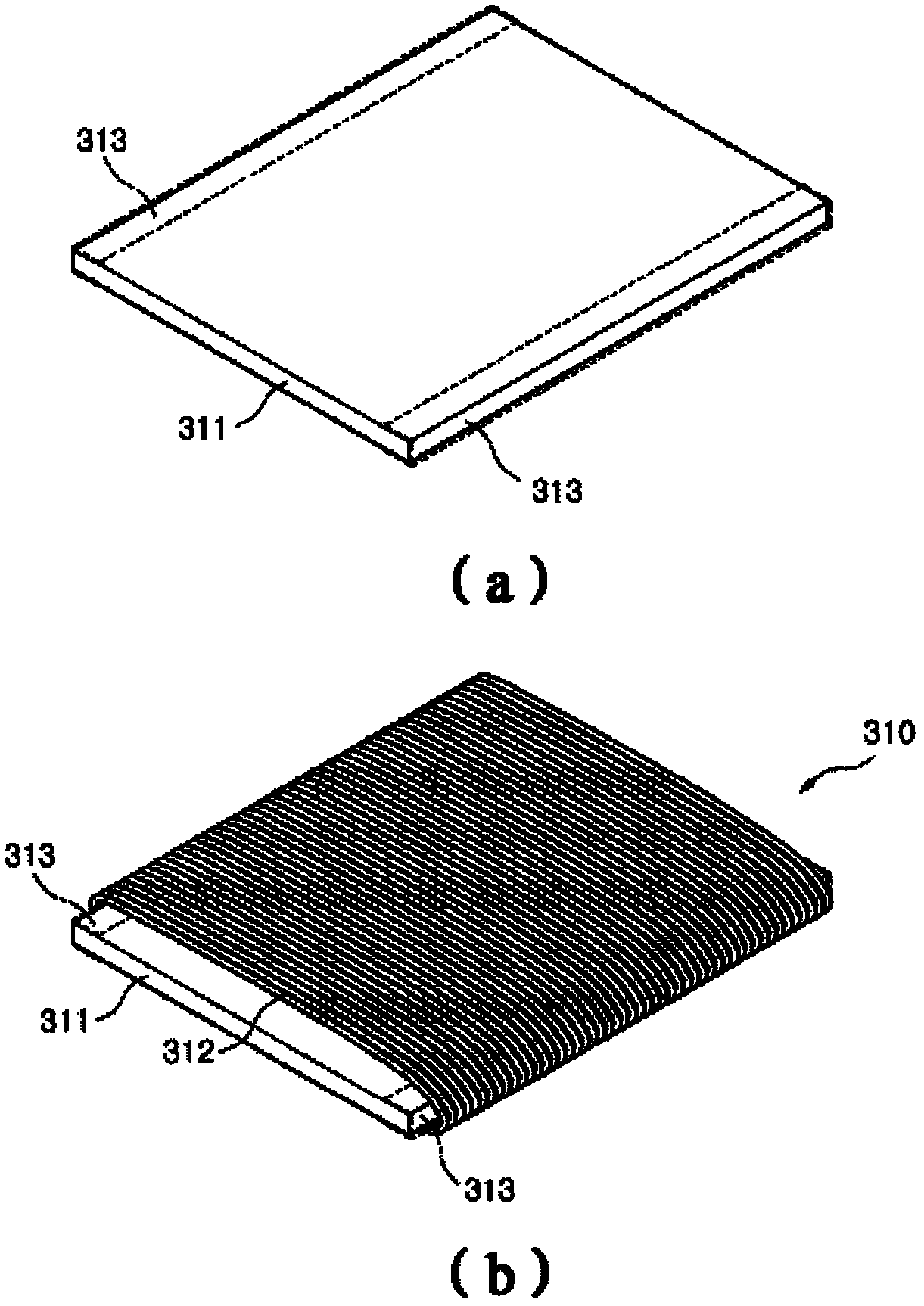

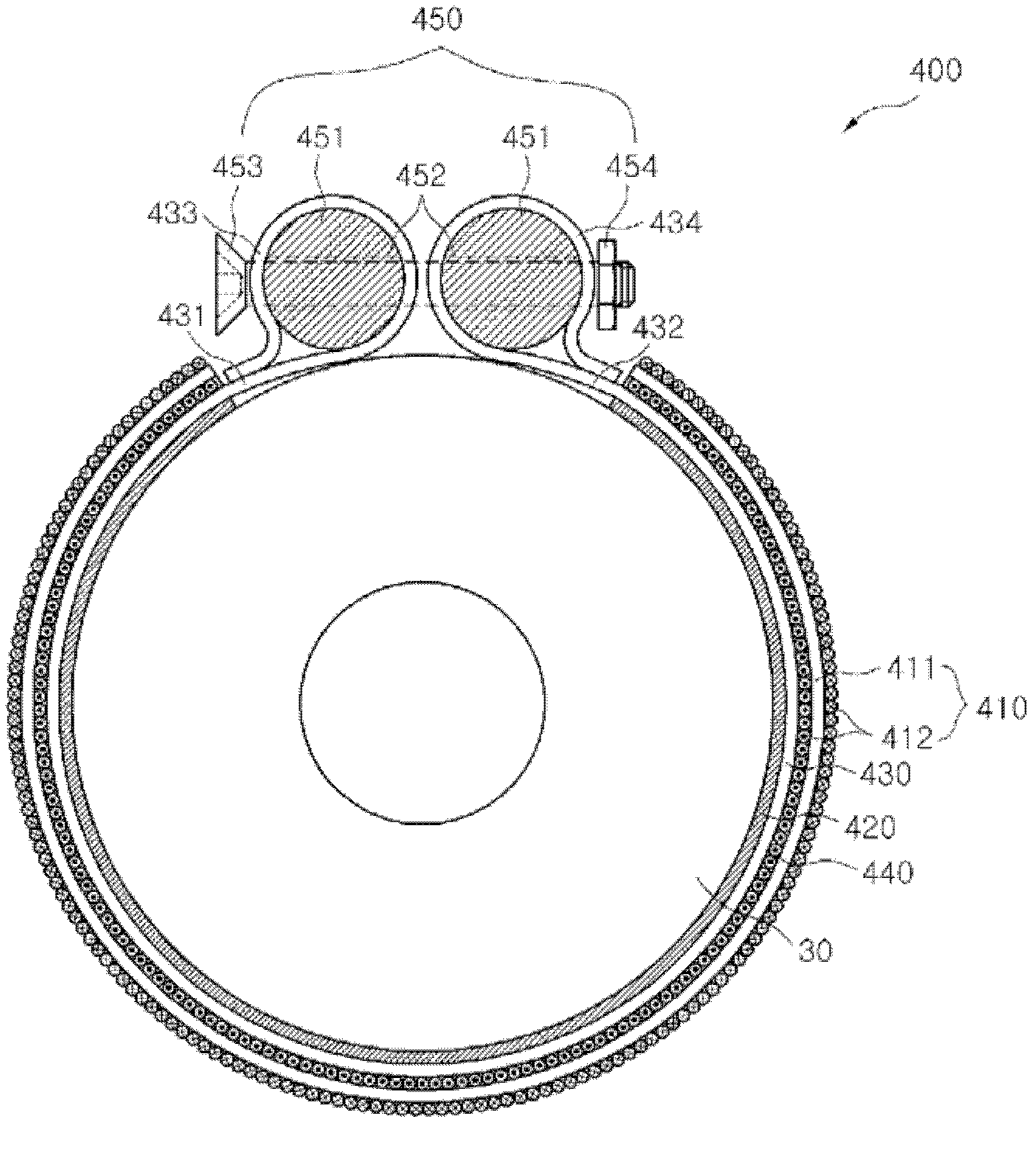

[0023] figure 1 It is a cross-sectional view of the transducer band 300 of the contact horizontal shear (SH) type guided wave magnetostrictive transducer according to an embodiment of the present invention, figure 2 for figure 1 The perspective view of the plate-shaped solenoid 310 of the contact SH guided wave magnetostrictive transducer in image 3 It is a cross-sectional view showing the arrangement of the ring-shaped transducing band 400 of the contact-type SH guided-wave magnetostrictive transducer according to another embodiment of the present invention.

[0024] refer to Figure 1~3 , the contact SH guided wave magnetostrictive transducer includes two parts, namely two transducing bands 300, 400 and an RF coil (not shown). The transducer bands 300, 400, which are part of the contact-type SH g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com