Self-circulation cyclone separator

The technology of a cyclone separator and a separation cylinder is applied in the direction of a cyclone device, a device whose axial direction of the cyclone can be reversed, etc., which can solve the problems of poor separation ability of fine powder and affecting the use of the cyclone separator.

Inactive Publication Date: 2012-05-30

YANCHENG INST OF TECH

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the biggest weakness of the cyclone separator is the relatively poor separation ability of fine powder, which affects the use of the cyclone separator in more occasions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

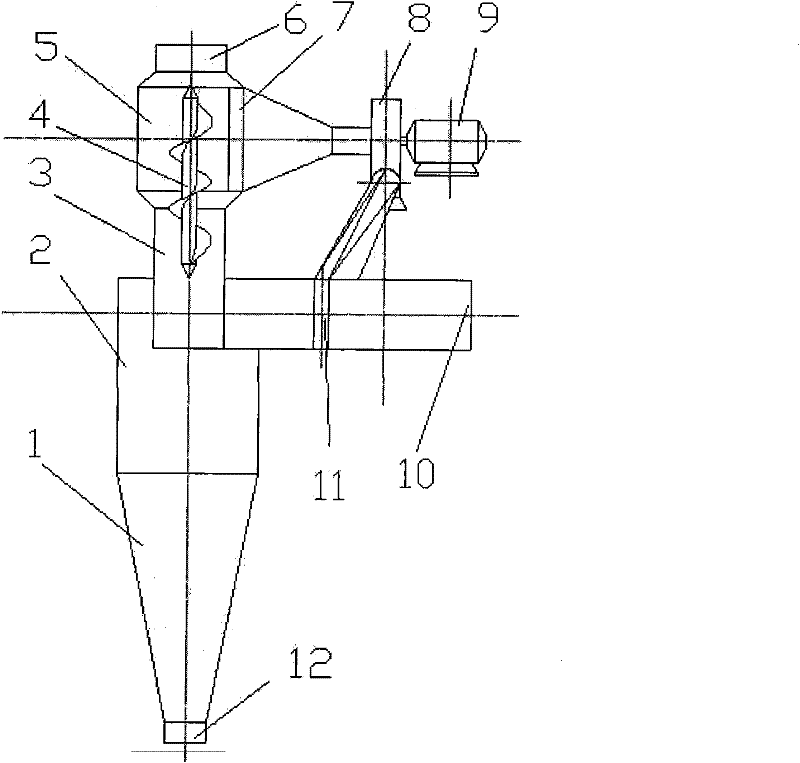

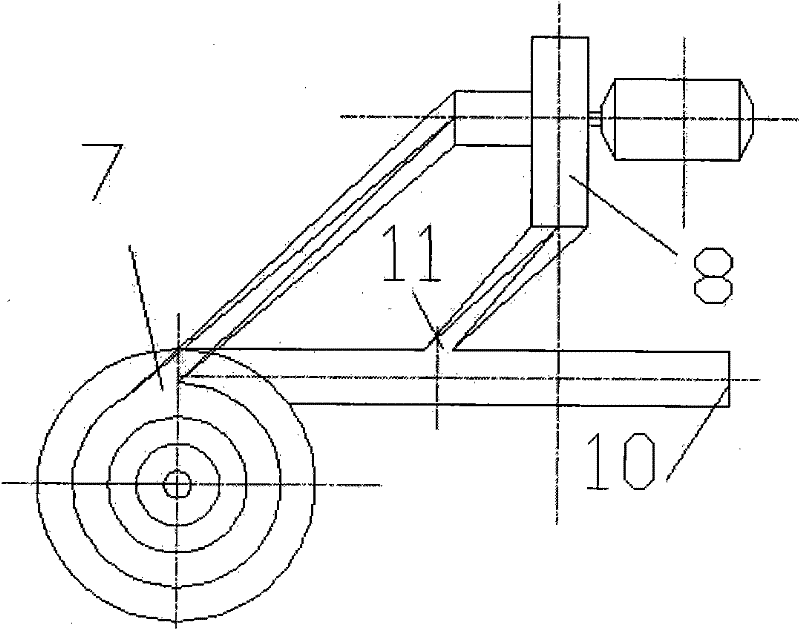

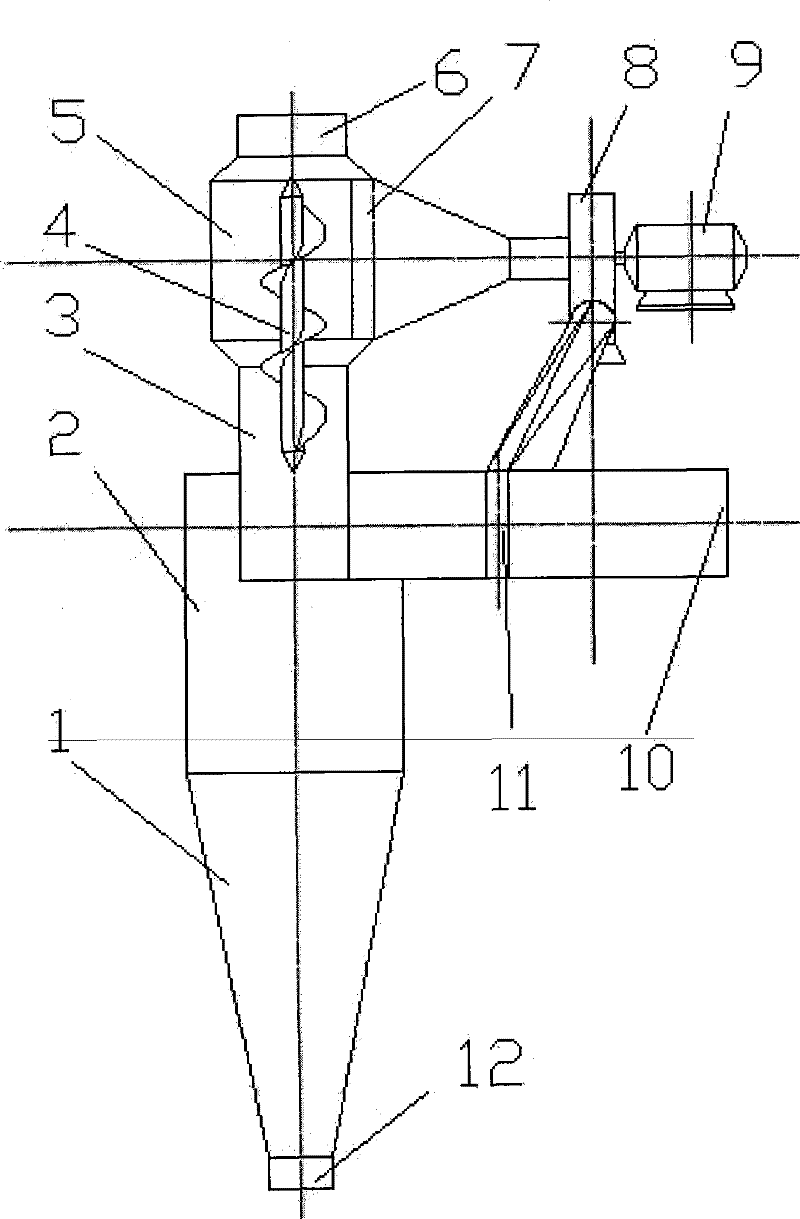

[0007] Depend on figure 1 and figure 2 It can be seen from the structure that the structure of the system is mainly based on sheet metal welding, and the motor and fan can be purchased as a complete set, which is easy to implement.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of atmosphere environmental protection and powder processing, and relates to a cyclone separator with a self-circulation function. According to the invention, a secondary separating cylinder and a screw apparatus are arranged in addition at an exhaust pipe of a common cyclone separator. Relatively high rotation speed is maintained in the gas flow in the exhaust pipe. With the guiding function of the screw apparatus, the gas flow can be forced to rotate, such that secondary separation of dust particles is realized in the secondary separating cylinder. An outlet is provided on the wall of the secondary separating cylinder. Dust obtained in the secondary separation process is pumped out by a blower, and is delivered to a gas inlet of the cyclone separator by using the blower. With the blower, the dust is then delivered into the cyclone separator, such that the circulation of part of the gas flow is formed. With the circulation, leaked dust can be delivered back to the cyclone separator; the separation efficiency can be improved; and the volume of current velocity in a flow field can be controlled through the controlling over a circulation gas volume. The self-circulation cyclone separator comprises: a cone (1), a primary separating cylinder (2), a primary exhausting port (3), the screw apparatus (4), the secondary separating cylinder (5), a circulation gas flow inlet (7), the blower (8), a dust-containing gas flow inlet (10), a circulation gas flow outlet (11), a dust discharging port (12), and the like.

Description

technical field [0001] The invention relates to a separation device for separating dust from air flow by using high-speed rotation of dust-containing gas, and belongs to the technical fields of atmospheric environmental protection and powder treatment. Background technique [0002] The currently widely used cyclone separator has a simple structure and is convenient to manufacture, use and maintain. It uses the rotation of the dust-laden airflow to make the dust particles in the airflow generate a certain inertial centrifugal force, and the rotating dust particles move to the periphery under the action of the inertial centrifugal force, and fall down after hitting the wall of the cylinder to achieve the purpose of dust collection. However, the biggest weakness of the current cyclone separator is its poor separation ability for fine powder, which affects the use of the cyclone separator in more occasions. Contents of the invention [0003] The invention provides a novel cyc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B04C5/30

Inventor 孙俊兰姜大志

Owner YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com