Plasma etching device, wafer fixture, and method for setting wafer

A technology for etching equipment and wafers, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve the problems of no directionality, waste of space, increased working time and labor costs, etc., to achieve the best space utilization and improve production Effective, easy-to-locate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the drawings and embodiments:

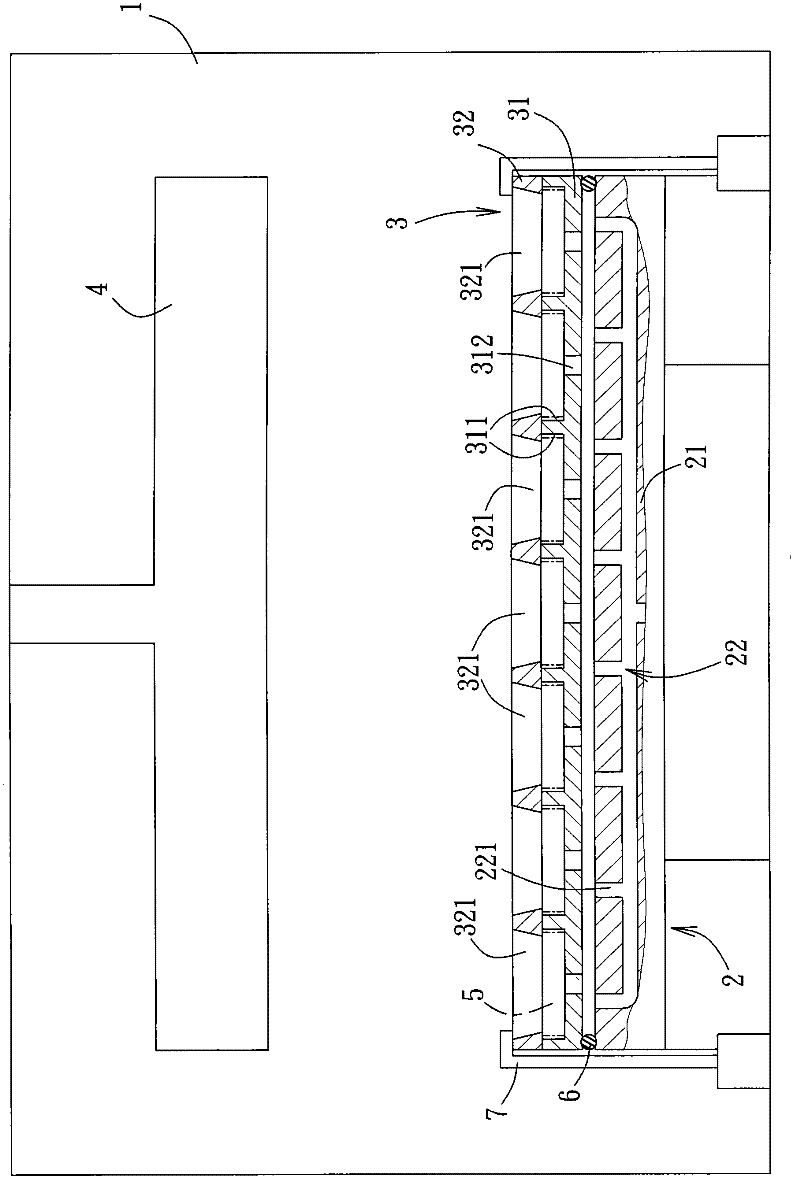

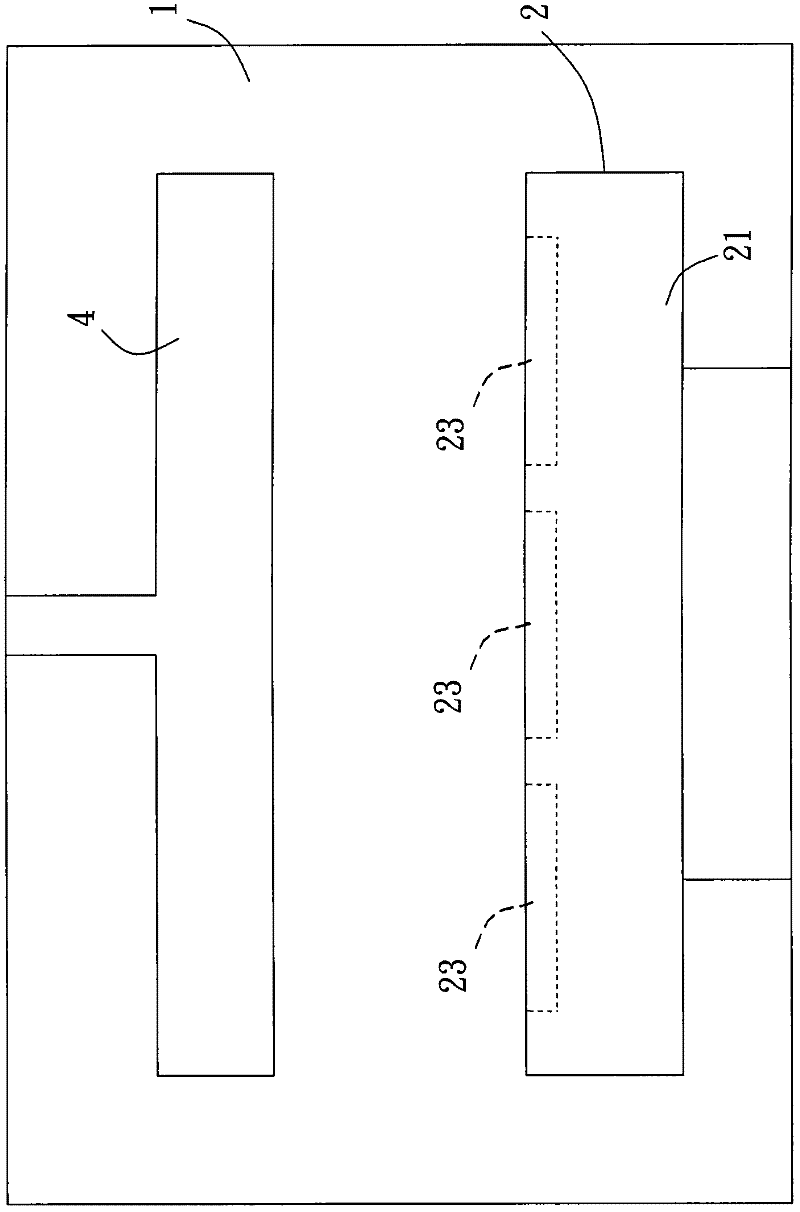

[0032] See figure 2 , The first preferred embodiment of the plasma etching equipment of the present invention can be provided with a plurality of wafers 5, including a reaction chamber 1, a bottom electrode 2, a wafer jig 3 and one set in the reaction chamber 1 It corresponds to the upper electrode 4 located above the lower electrode 2.

[0033] The lower electrode 2 is arranged in the reaction chamber 1, has a square body 21 and a cooling system 22. The cooling system 22 includes a plurality of air outlet holes 221 arranged on the top surface of the main body 21 and facing the wafer jig 3. In this embodiment, the cooling system 22 is connected to a gas supply system (not shown) outside the reaction chamber 1 so as to Cooling gas is provided when the wafer 5 is etched.

[0034] The wafer jig 3 covers the bottom electrode 2 and has a square bottom plate 31 and a cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com