Vinyl chloride resin composition for transparent products

A technology of vinyl chloride resin and composition, which is applied in the field of vinyl chloride resin composition for transparent products with tin-based stabilizers, and can solve the problems of lack of transparency, inability to obtain, and no mention of zinc-modified hydrotalcite. , to achieve high transparency, excellent heat resistance and coloring resistance, excellent heat resistance and coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、 comparative example 1~29

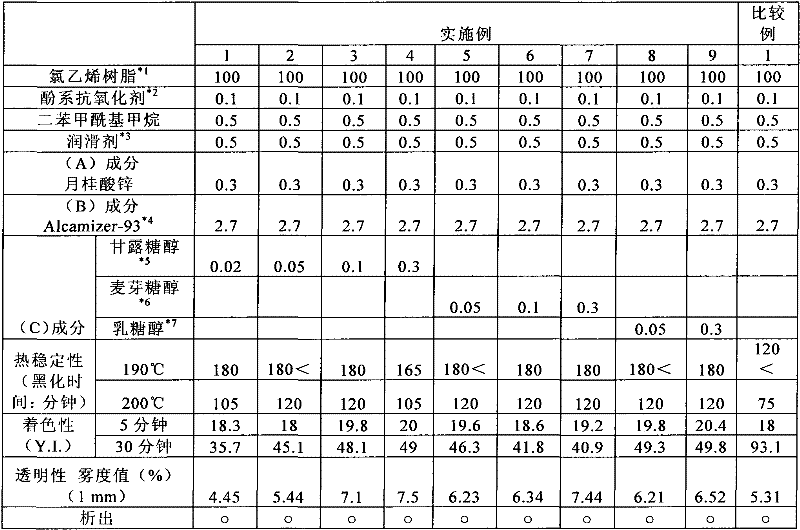

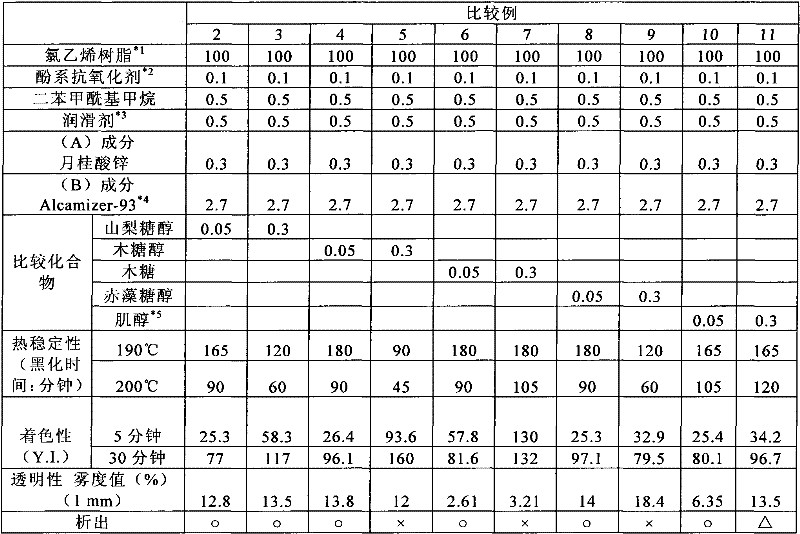

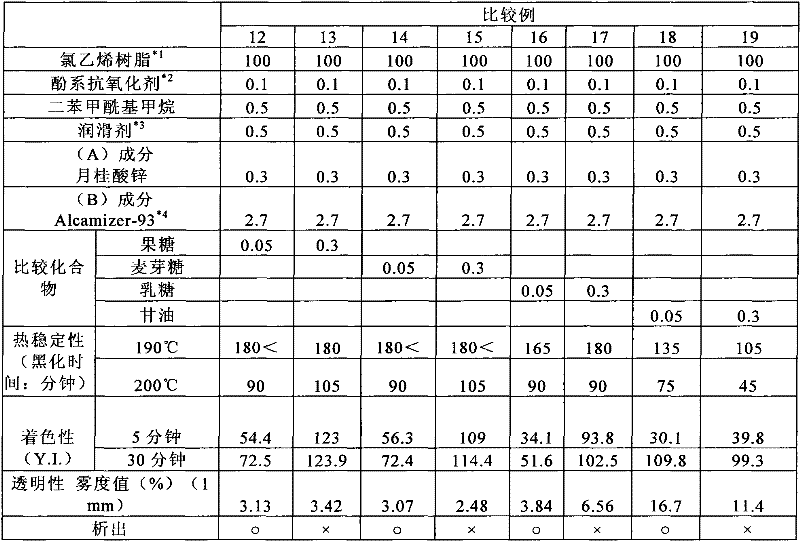

[0118] The formulations listed in the following Table 1 were blended using a Henschel mixer, and kneaded using a roller under the conditions of 170° C.×30 rpm×0.6 mm×3 min to produce a sheet. The surface of the drum after kneading was visually observed, and was performed under the following evaluation conditions. Among them, 0.6mm is the interval between the rollers. The results are shown in Table 1.

[0119] The obtained sheet was placed in a Geer oven at 190° C. and 200° C., and the blackening time (minutes) was measured respectively as . The results are shown in Table 1.

[0120] In addition, the 0.6-mm-thick sheets obtained above were bonded together, and press-processed at 190 degreeC for 5 minutes or 30 minutes, and each 1-mm-thick sheet was produced.

[0121] Using these sheets, a colorability test and a transparency test were performed by the following methods. The results are shown in Table 1.

[0122] In addition, as a comparative example, a composition in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com