Pneumatic valve for braking system of truck

A braking system, pneumatic valve technology, applied in the direction of control valve and air release valve, brake, brake components, etc., can solve problems such as hidden safety hazards, traffic accidents, brake system control delay, etc., to achieve good sealing performance and response. Speed block, control speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

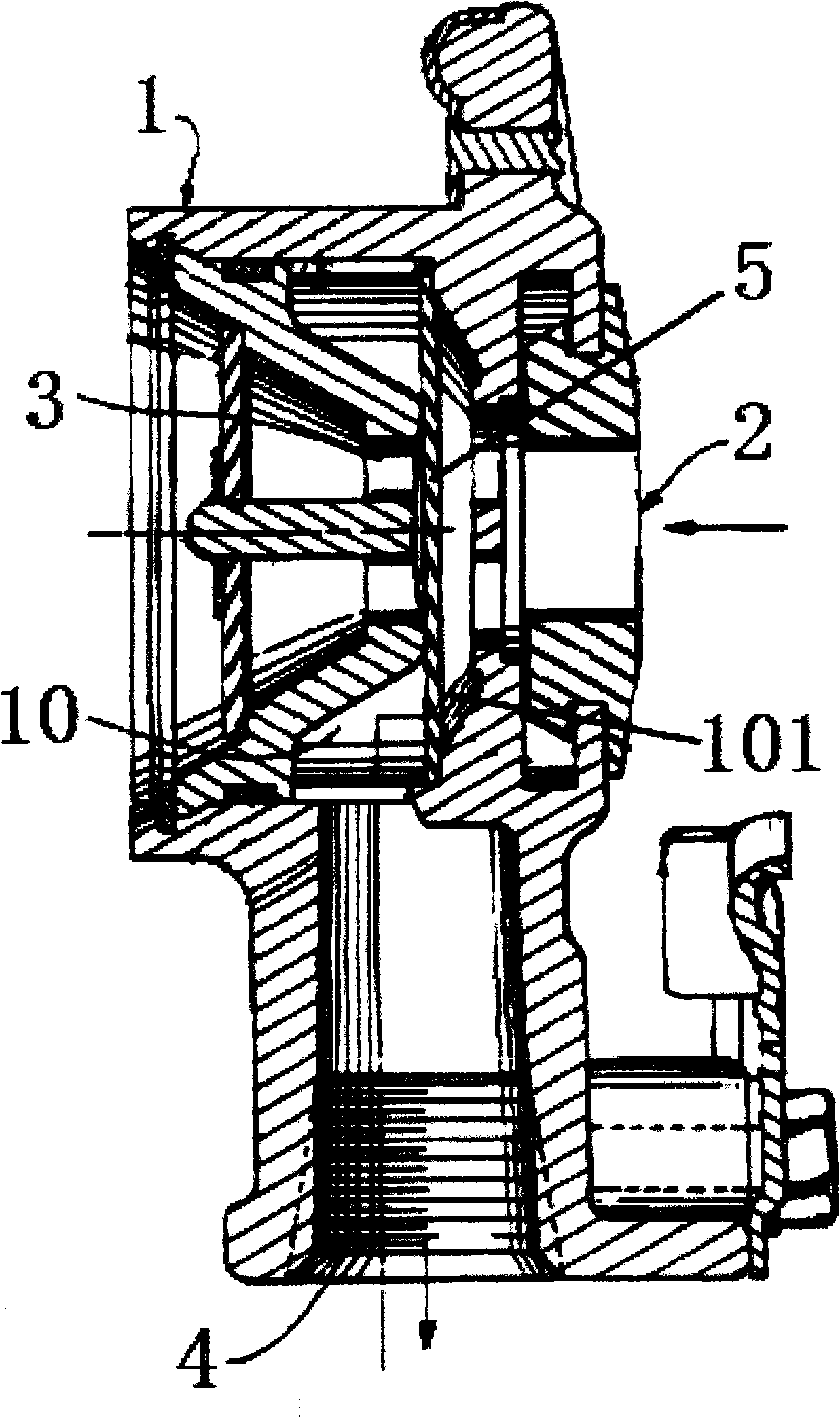

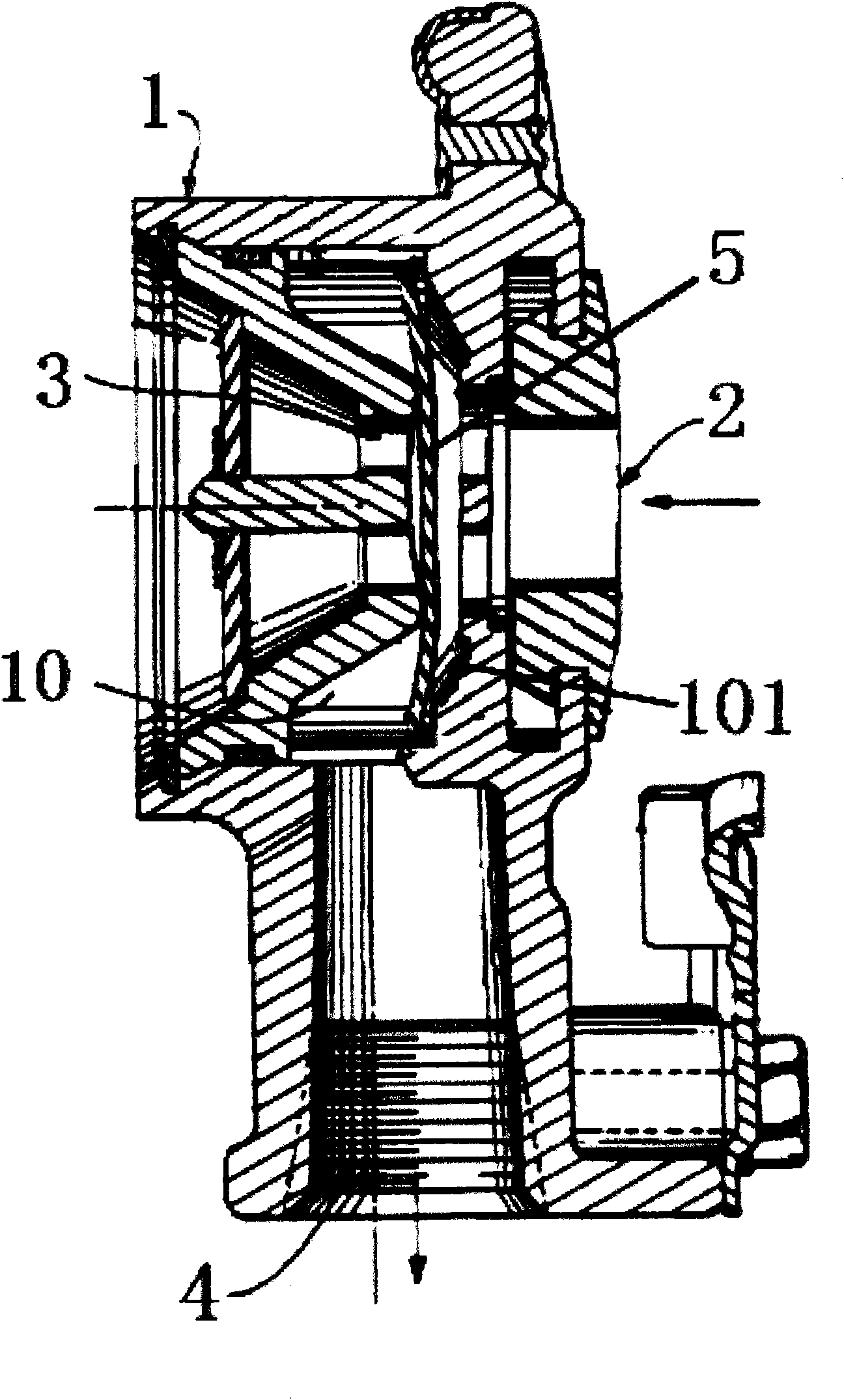

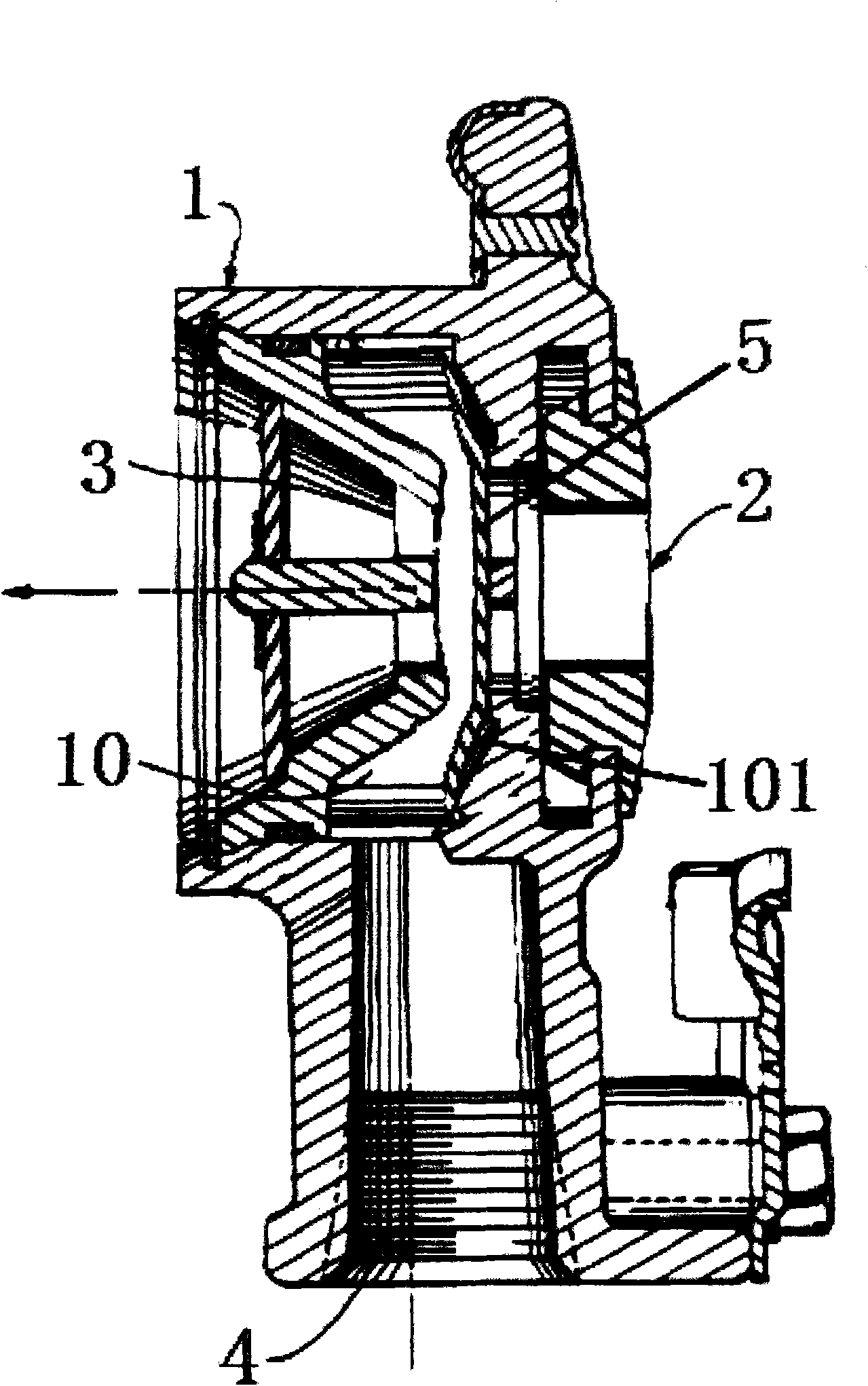

[0018] Such as figure 1 As shown, the pneumatic valve for the truck brake system according to the embodiment of the present invention includes a valve body 1 with a valve cavity 10, and the valve body 1 is provided with an air inlet 2 and an exhaust port respectively connected with the valve cavity 10. 3 and air outlet 4, the valve cavity 10 is provided with an elastic seal 5 that closes the exhaust port 3 when the pneumatic valve is inflated, and closes the air inlet 2 when the pneumatic valve is deflated. The elastic seal 5 is located between the air inlet 2 and Between exhaust ports 3.

[0019] In this embodiment, an annular seat 101 is provided in the valve chamber 10 , and the elastic sealing member 5 is fixed on the annular seat 101 .

[0020] In this embodiment, the axes of the air inlet 2 and the air outlet 3 are the same.

[0021] In this embodiment, the exhaust port 3 is an annular hole. The outside of the exhaust port 3 is provided with a trumpet-shaped exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com