Double-film drip irrigation pipe/belt with water permeable side seams

A drip irrigation pipe and membrane edge technology, applied in the field of double-film drip irrigation pipe or drip irrigation belt, and drip irrigation pipe/belt with seepage at the side seam, can solve problems such as blocking the water outlet, reduce operating energy consumption, reduce production costs, and simplify equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

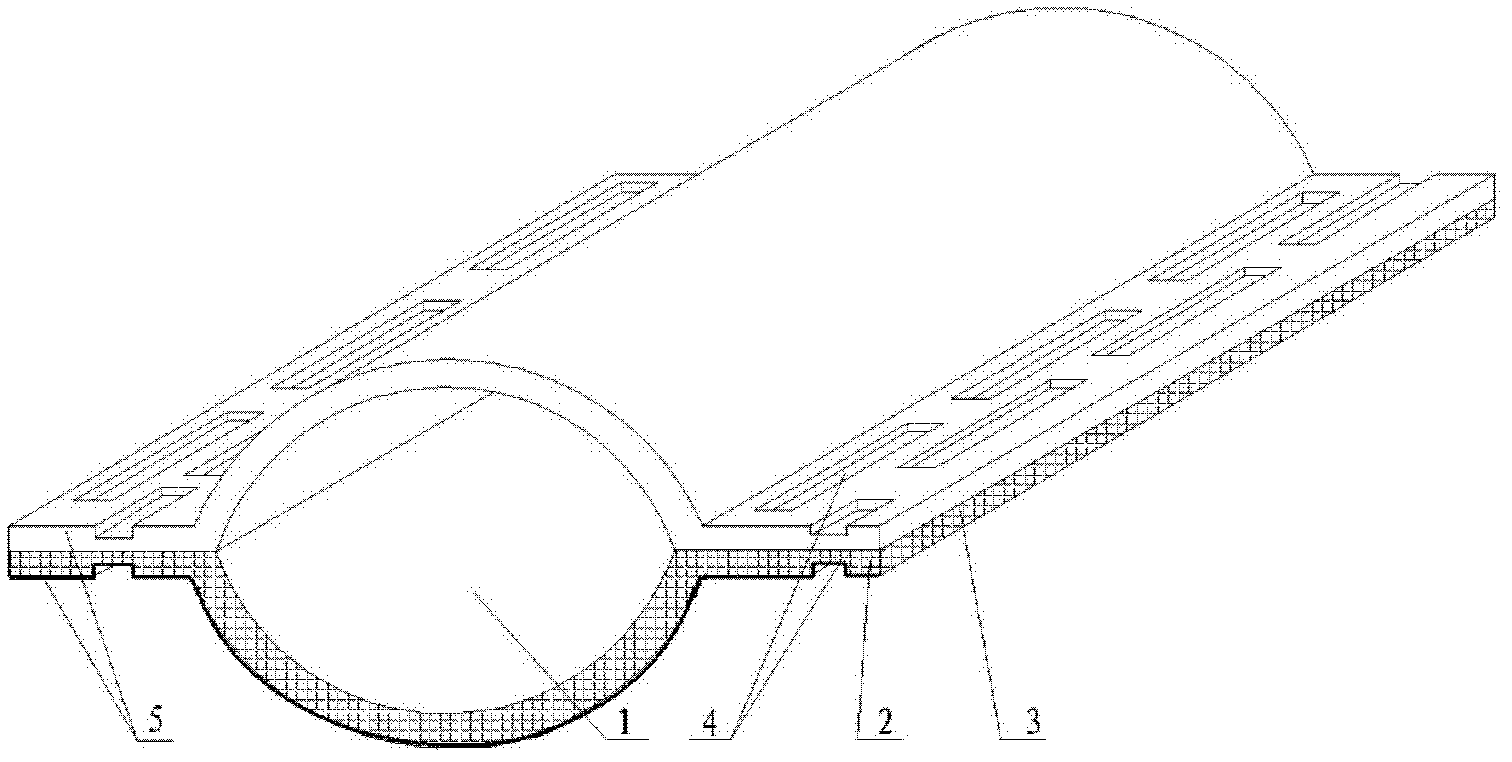

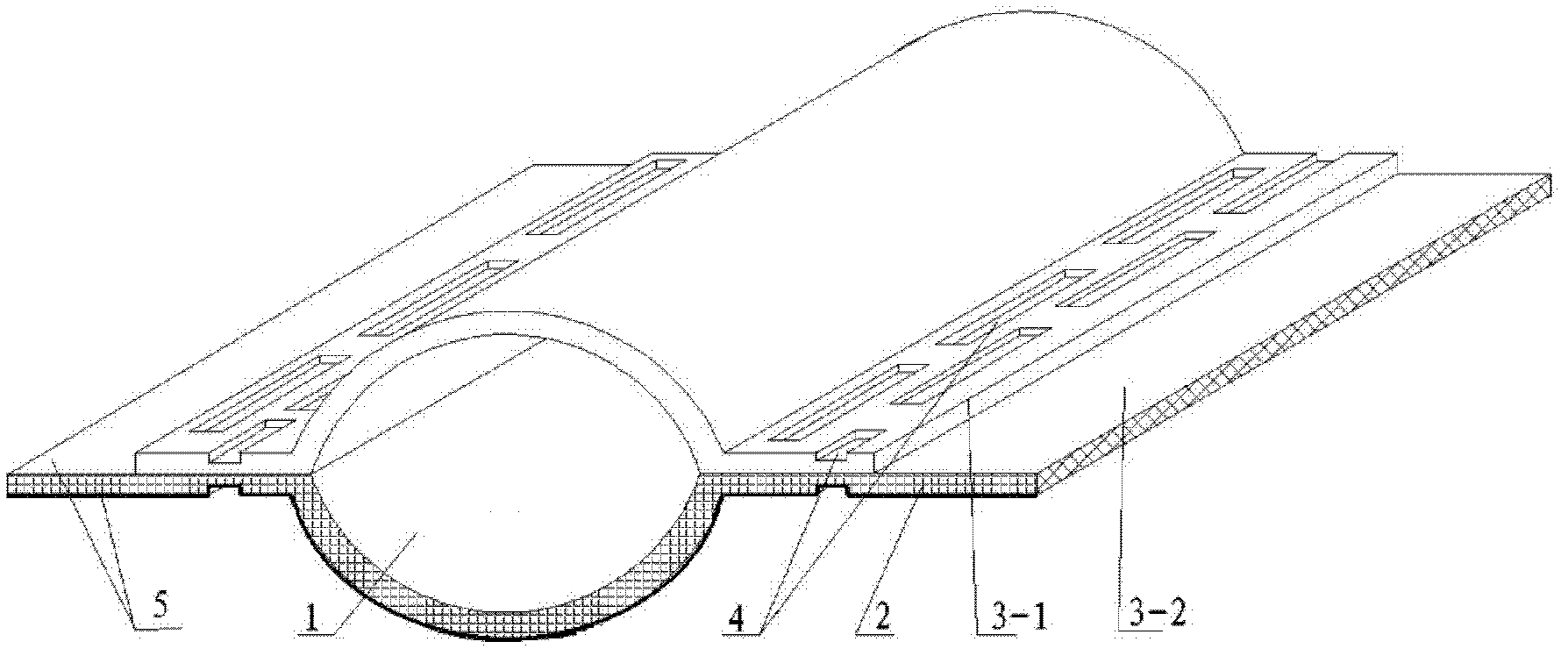

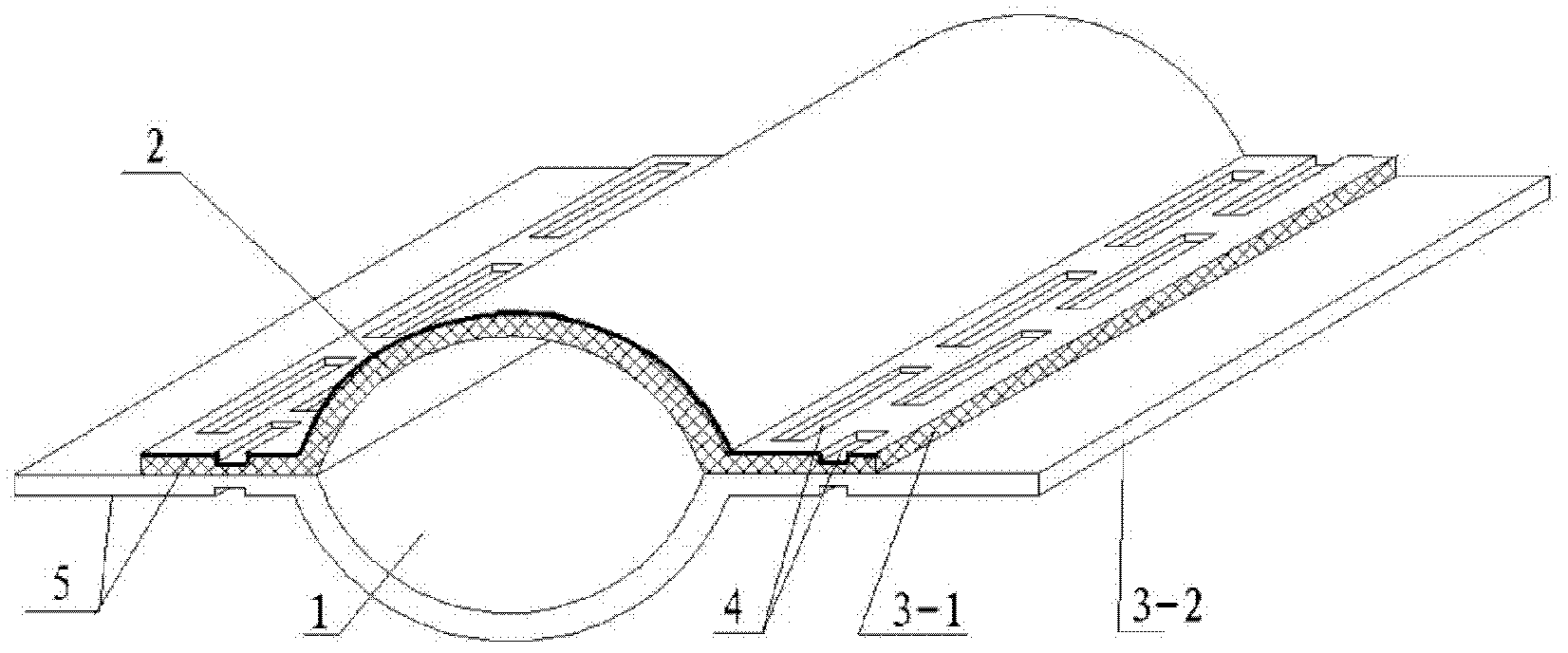

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The technical key of the present invention is to create an original combination of ordinary film and non-woven fabric or open foam layer 2 provided with a water-blocking film layer 5 on the surface as the main material of the drip irrigation pipe or drip irrigation belt. With the help of capillary action of non-woven fibers or open foam layer, the irrigation water seeps out from the drip irrigation pipe / passing water channel to the side seam. Discontinuous bonding points 4 are set on the water seepage side seam 3, and the gaps between the bonding points on the side seam form a water seepage channel. The amount of dripping water per unit length of drip irrigation or infiltration irrigation can be controlled by the spacing of the bonding points. If the spacing is large, the amount of dripping water per unit time and the same pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap