Workpiece positioning device

A technology of positioning device and workpiece, applied in positioning device, feeding device, storage device, etc., can solve the problems of complex structure and poor positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

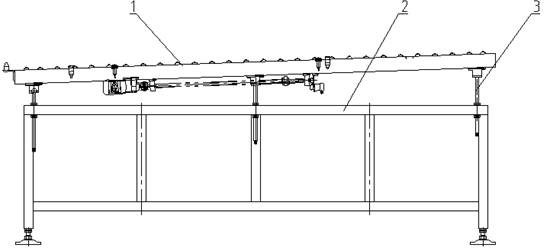

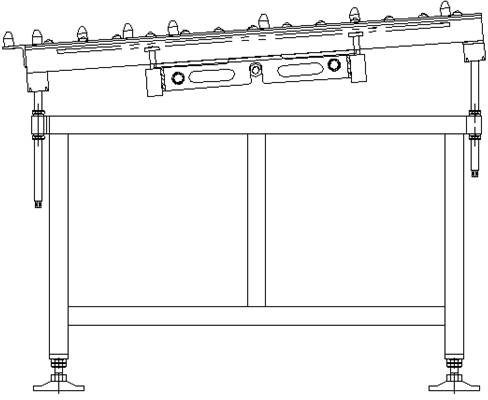

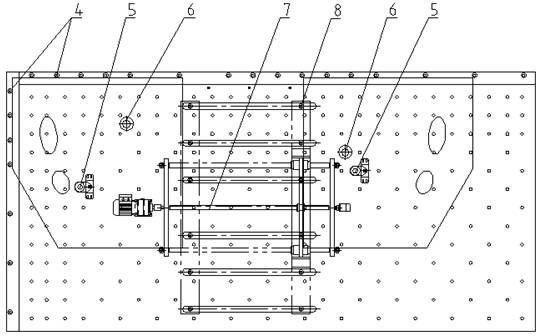

[0025] Refer to the attached figure 1 with 2 The shown workpiece positioning device includes a table 1, which is a state of use in the figure. It can be seen from the combination of the two figures that the rectangular table shown in the figure is a diagonally inclined table. Correspondingly, one corner of the table is the reference corner, for image 3 In the upper left corner of the table, the table forms an inclined table whose reference angle is lower than other parts of the table, and the inclination angle is greater than the friction angle of the workpiece to be positioned on the table; The positioning element is used to constrain the degree of freedom of the workpiece sliding on the table, and the corresponding two degrees of freedom are orthogonal.

[0026] It should be noted that the limitation on the friction angle is a basic condition, and it should be slightly larger than this value in actual use. Those skilled in the art can select it through the working hours o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com