Stretching type blow molding machine as well as blow molding method and product thereof

A blow molding machine and stretching technology, applied in the field of blow molding, can solve the problems of easy damage, scattered distribution of molecular chains, and insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

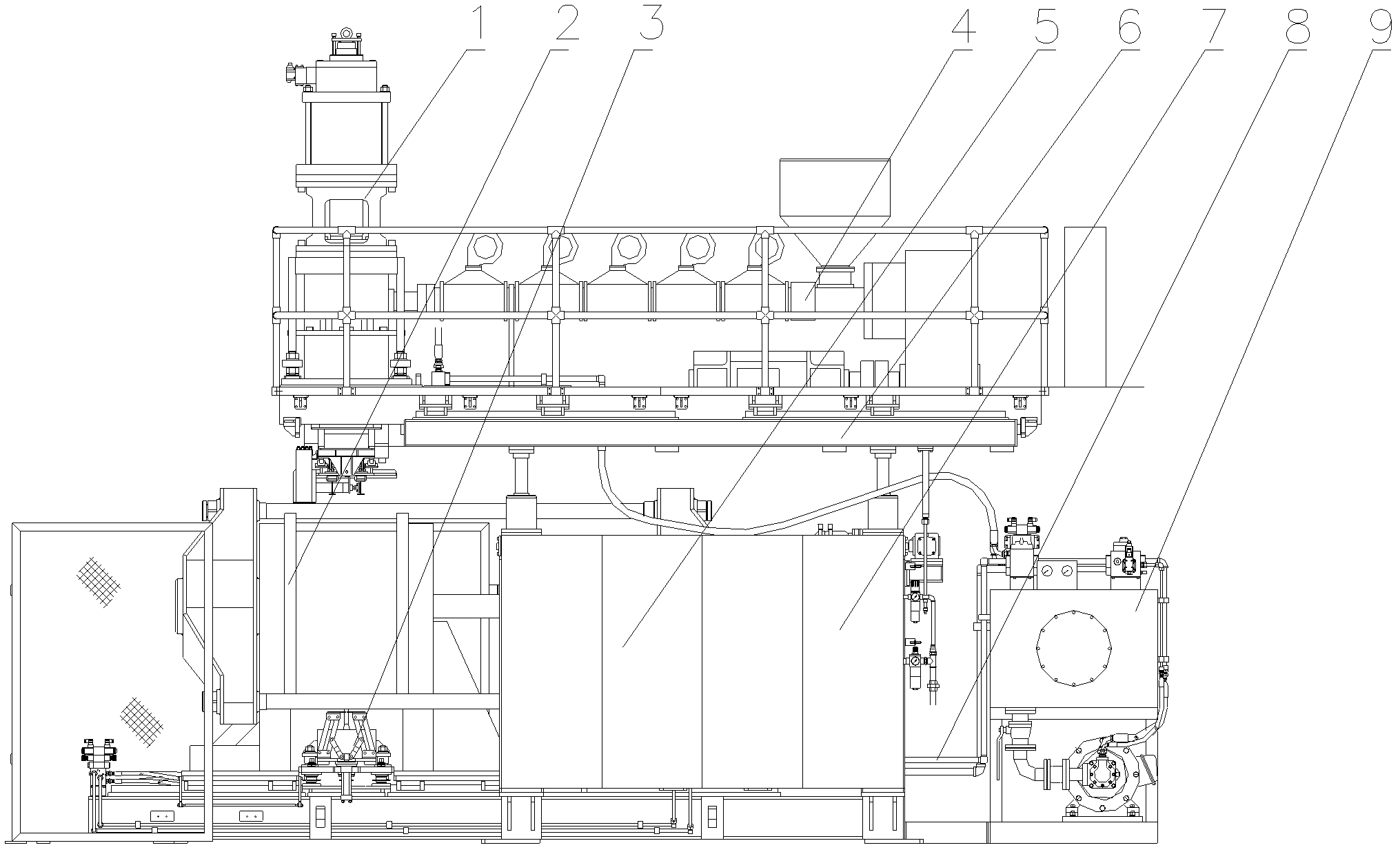

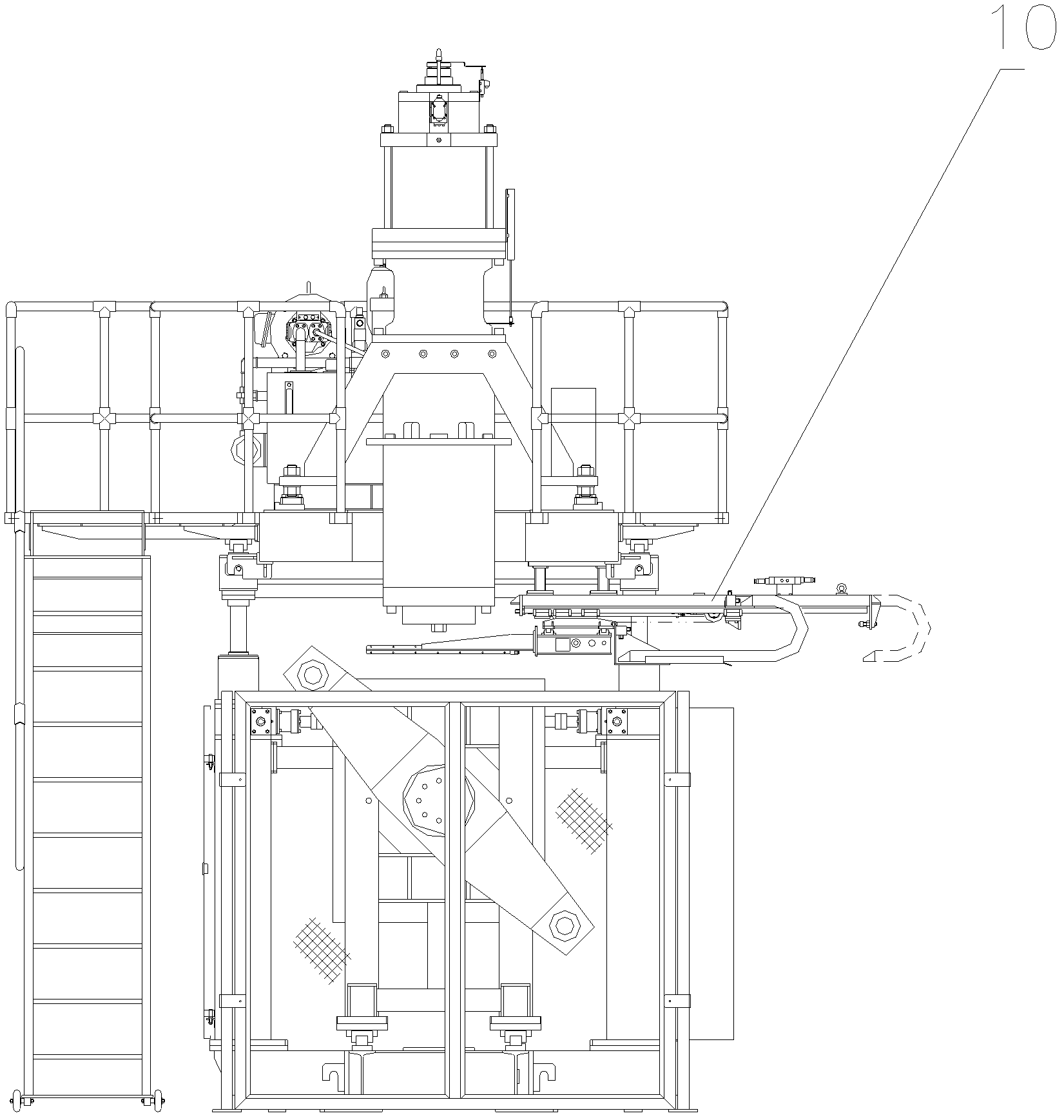

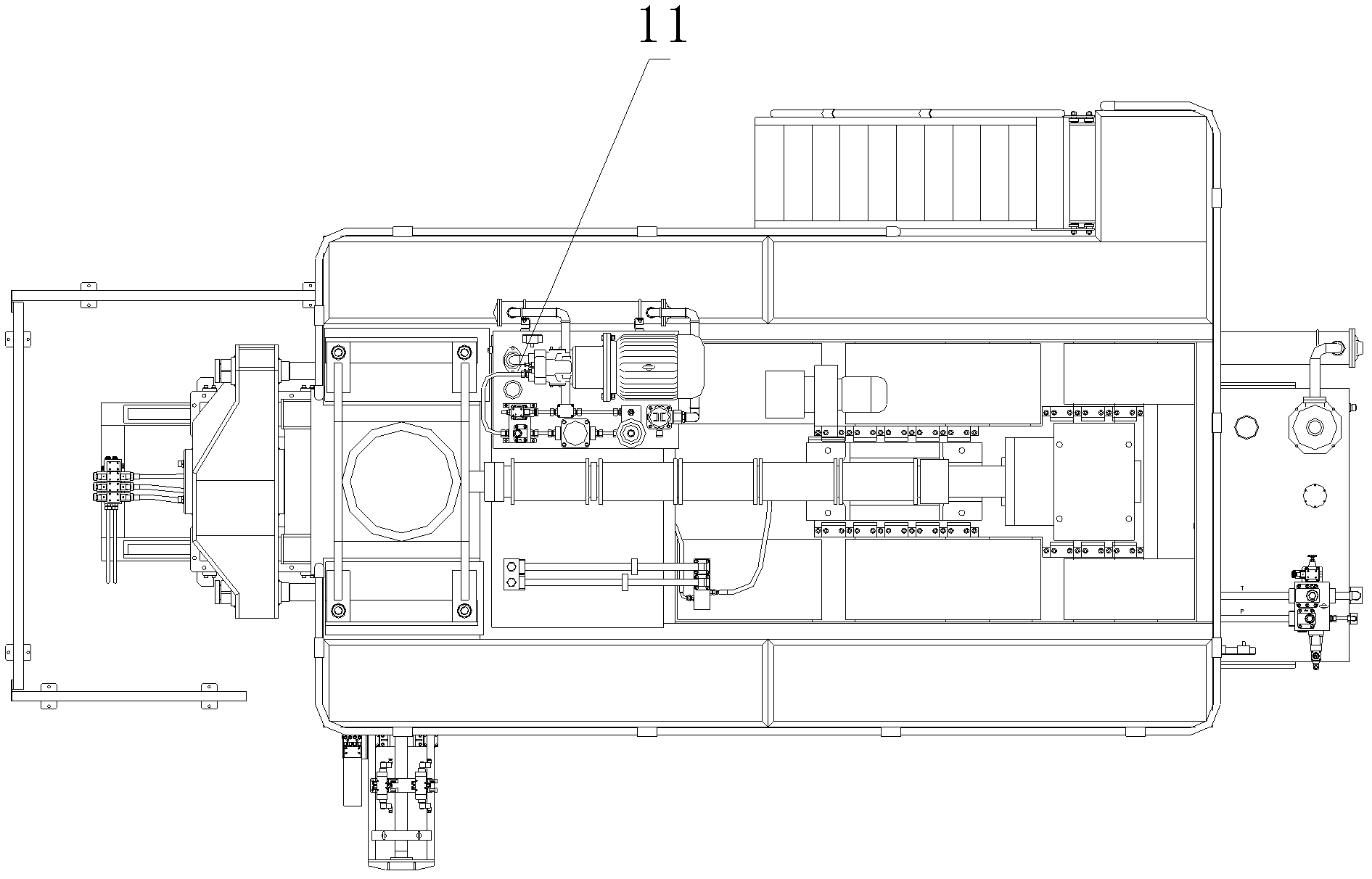

[0037] see Figure 1 to Figure 3 , the present invention discloses a blow molding device, comprising: a frame 6, an extrusion mechanism 4, a die head 1, a mold clamping mechanism 2, a blowing mechanism 3, a manipulator 10, a controller 20 (including an electrical system 5, a pneumatic System 7, hydraulic system 9), pipeline system 8, hydraulic servo power supply 11. The controller 20 is respectively connected to the extrusion mechanism 4, the die head 1, the mold clamping mechanism 2, the down blowing mechanism 3, and the manipulator 10 to control the extrusion mechanism 4, the die head 1, the mold clamping mechanism 2, and the down blowing mechanism 3 , Manipulator 10 cooperative action.

[0038] The frame 6 is mainly composed of pillars and frame-shaped beams to support the manipulator 10 and the die head 1. The pillars are formed columnar members, the bottom end of which is provided with a flange for fixed connection with the common base, and the top end is used to support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com