Storage box for new energy automobile cell

A technology for new energy vehicles and storage boxes, applied in battery boxes/jackets, secondary batteries, battery pack components, etc. Easy to organize and firmly fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

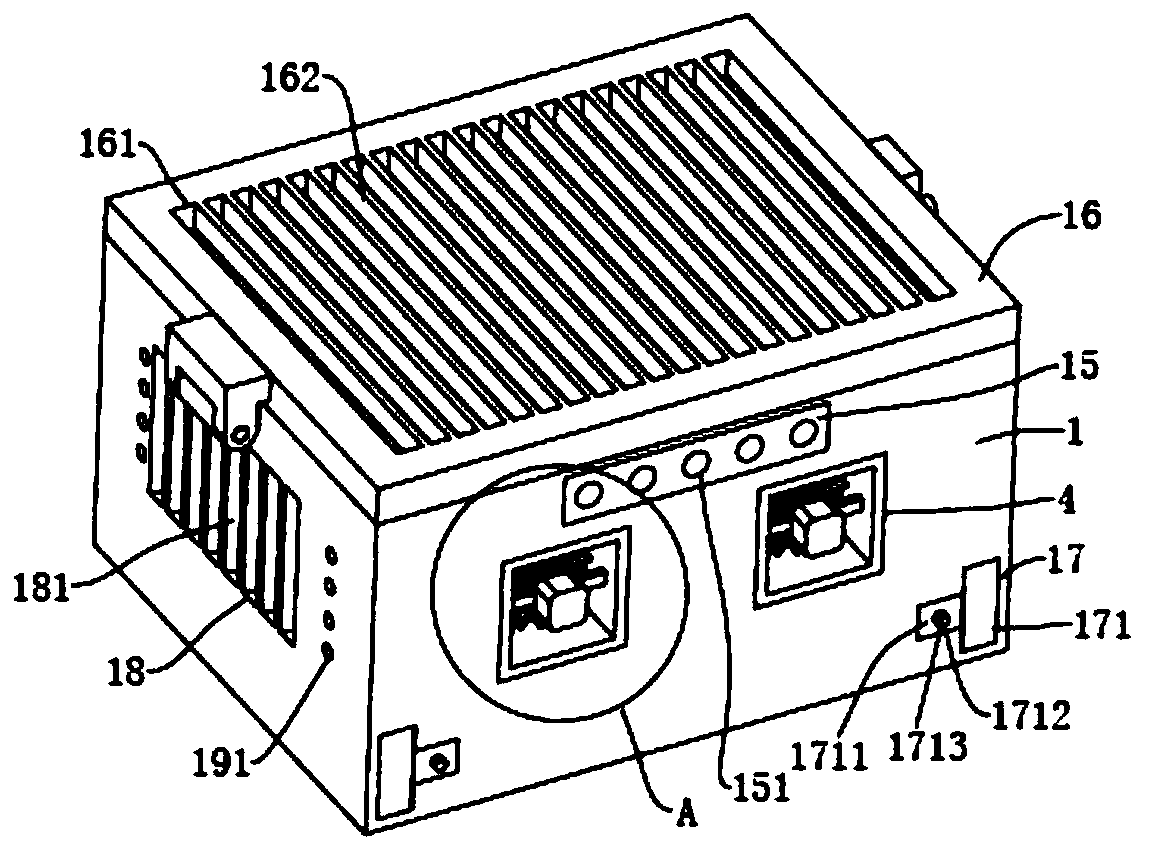

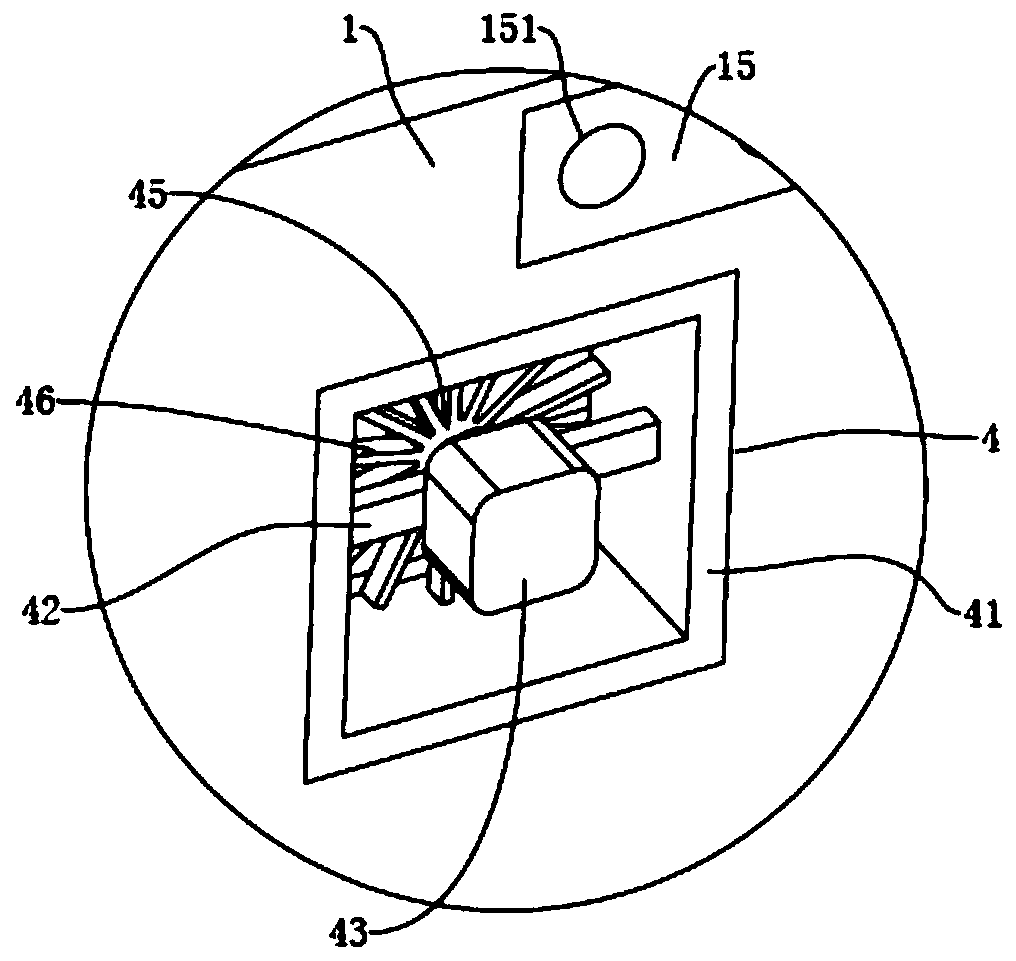

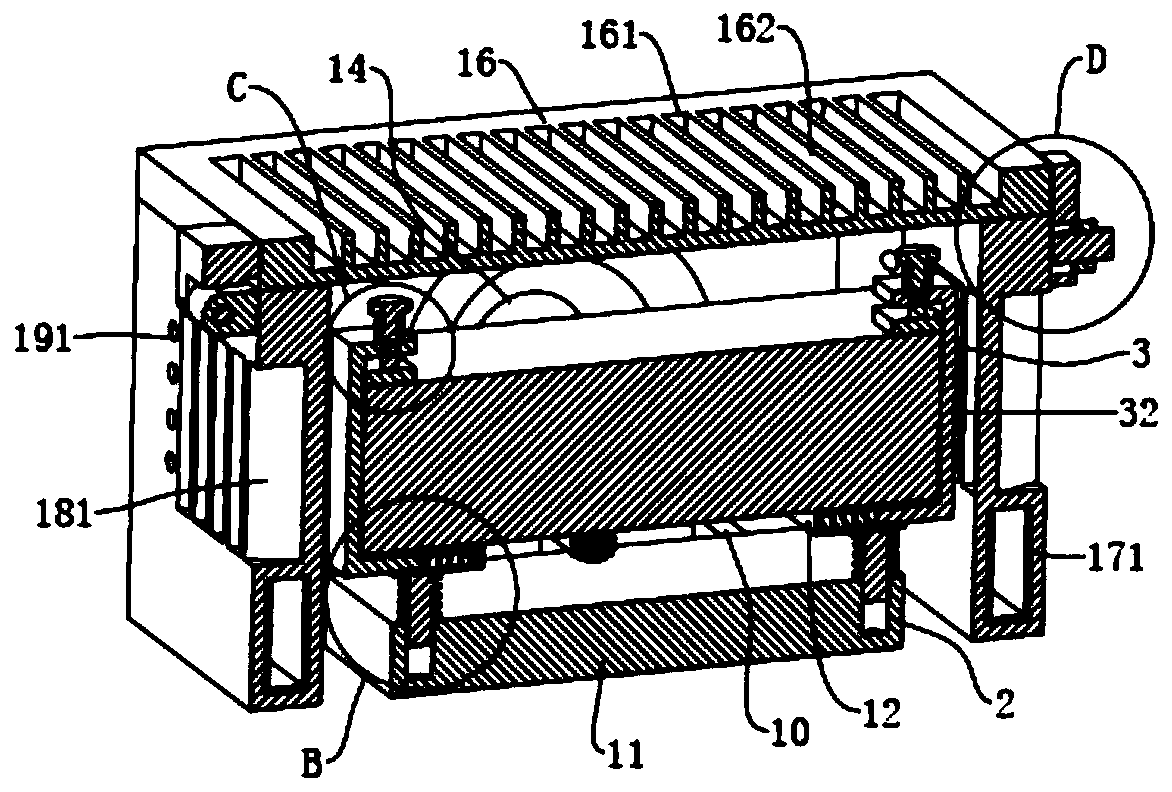

[0054] refer to figure 1 , figure 2 and image 3 , a new energy vehicle battery storage box, including a box body 1 with openings on the top and bottom, and also includes six connecting rods 10 fixed at the opening at the bottom of the box body 1, wherein the six connecting rods 10 are jointly fixed on the support base 11 At the same time, a back-shaped plate 12 is arranged above the support seat 11, and the top of the back-shaped plate 12 is used to place new energy batteries. The battery on the board 12 provides shock absorption; in order to make the battery above the back-shaped board 12 can be firmly fixed, two sets of locking components for fixing the new energy battery placed on the back-shaped board 12 are provided on the back-shaped board 12 3. In order to make the battery in the box body 1 get good heat dissipation, two grooves 13 are opened on one side of the box body 1, and the exhaust assembly 4 is respectively installed and fixed in the two grooves 13, and the ...

Embodiment 2

[0065] The difference from Example 1 is that the surface of the back-shaped plate 12 is also coated with a layer of anti-fouling coating, because the surface of the back-shaped plate 12 needs to place batteries, and the top of the back-shaped plate 12 is easy to accumulate dust, in order to prevent dust Firmly stick on the top of the back-shaped plate 12, the surface of the back-shaped plate 12 is sprayed with a layer of antifouling coating, wherein the antifouling coating is prepared by the following method:

[0066]Take the following raw materials of each component by weight for later use: 80 parts of polytetrafluoroethylene, 40 parts of polycarbonate, 20 parts of sodium laureth sulfate, 20 parts of sodium lauroyl sarcosine, and 15 parts of trihydroxystearin , 20 parts of phenoxyethanol, 10 parts of citric acid, 15 parts of sodium benzoate, 8 parts of sodium chloride, 8 parts of cocoamidomethyl MEA;

[0067] S1. Prepare antifouling coating pre-preparation solution; mix and s...

Embodiment 3

[0073] The difference from Example 2 is the preparation of the back-shaped plate 12 surface antifouling coating, wherein the antifouling coating is prepared by the following method:

[0074] Take the following components by weight for subsequent use: 83 parts of polytetrafluoroethylene, 43 parts of polycarbonate, 23 parts of sodium laureth sulfate, 23 parts of sodium lauroyl sarcosinate, and 18 parts of trihydroxystearin , 22 parts of phenoxyethanol, 10 parts of citric acid, 15 parts of sodium benzoate, 8 parts of sodium chloride, 8 parts of cocamidomethyl MEA;

[0075] S1. Prepare antifouling coating pre-preparation solution; mix polytetrafluoroethylene, polycarbonate and sodium laureth sulfate evenly, then add to the reaction kettle and heat to 291°C, then keep warm for 12min;

[0076] S2. Preparation of antifouling coating solution: Cool the antifouling coating pre-preparation solution obtained in S1 to 207°C, then add sodium lauroyl sarcosinate, trihydroxystearyl essence, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com