Wire-threading mechanism applicable to rotary type machine

A transformation machine and threading technology, which is applied to packaging machines, packaging, and delivery of filamentous materials, can solve the problems of difficult threading and disassembly, difficult detection, and inconvenient maintenance, so as to improve work efficiency, easy detection, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

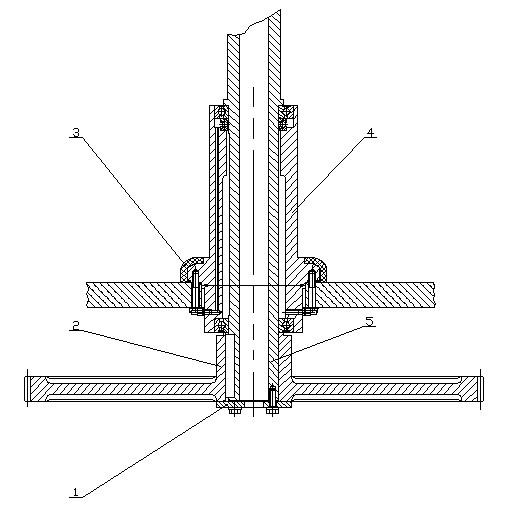

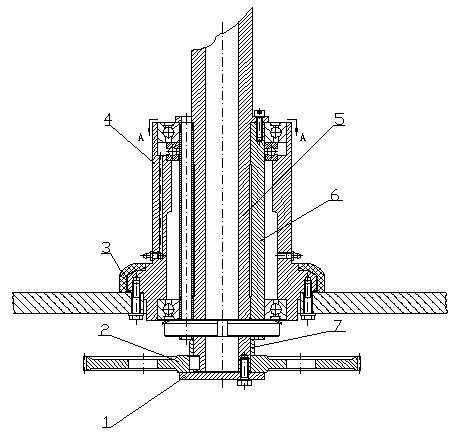

[0014] refer to Figure 2-6 , the specific embodiment adopts the following technical scheme: it includes the shaft end gland 1, the main gear 2, the dust cover 3, the main shaft base 4 and the main shaft 5, and it also includes the wire passing seat 6 and the shaft sleeve 7, the thread passing seat 6 is arranged on the outer wall of the main shaft 5 by means of clearance fit, and fixed on the main shaft 5 by a fixed structure, the main shaft base 4 is arranged on the outer side of the wire passing seat 6, and the outer wall of the bottom side of the main shaft base 4 is provided with a dustproof cover 3, The outer wall of the bottom side of the main shaft 5 is provided with a shaft sleeve 7 and the main gear 2 in sequence, and the bottom ends of the main shaft 5 and the main gear 2 are provided with a shaft end gland 1 .

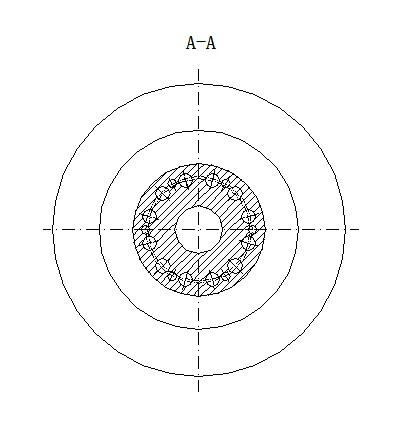

[0015] The central position of the thread passing seat 6 is provided with a shaft hole matched with the main shaft 5, several threading holes 62 are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com