Ball screw and sliding screw mutually nested type synchronous lifting photoelectric mast

A technology of ball screw and synchronous lifting, applied in the direction of lifting device, etc., can solve the problems of unstable base, difficult self-locking, large matching clearance, etc., and achieve the effect of improving positioning accuracy and reducing synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

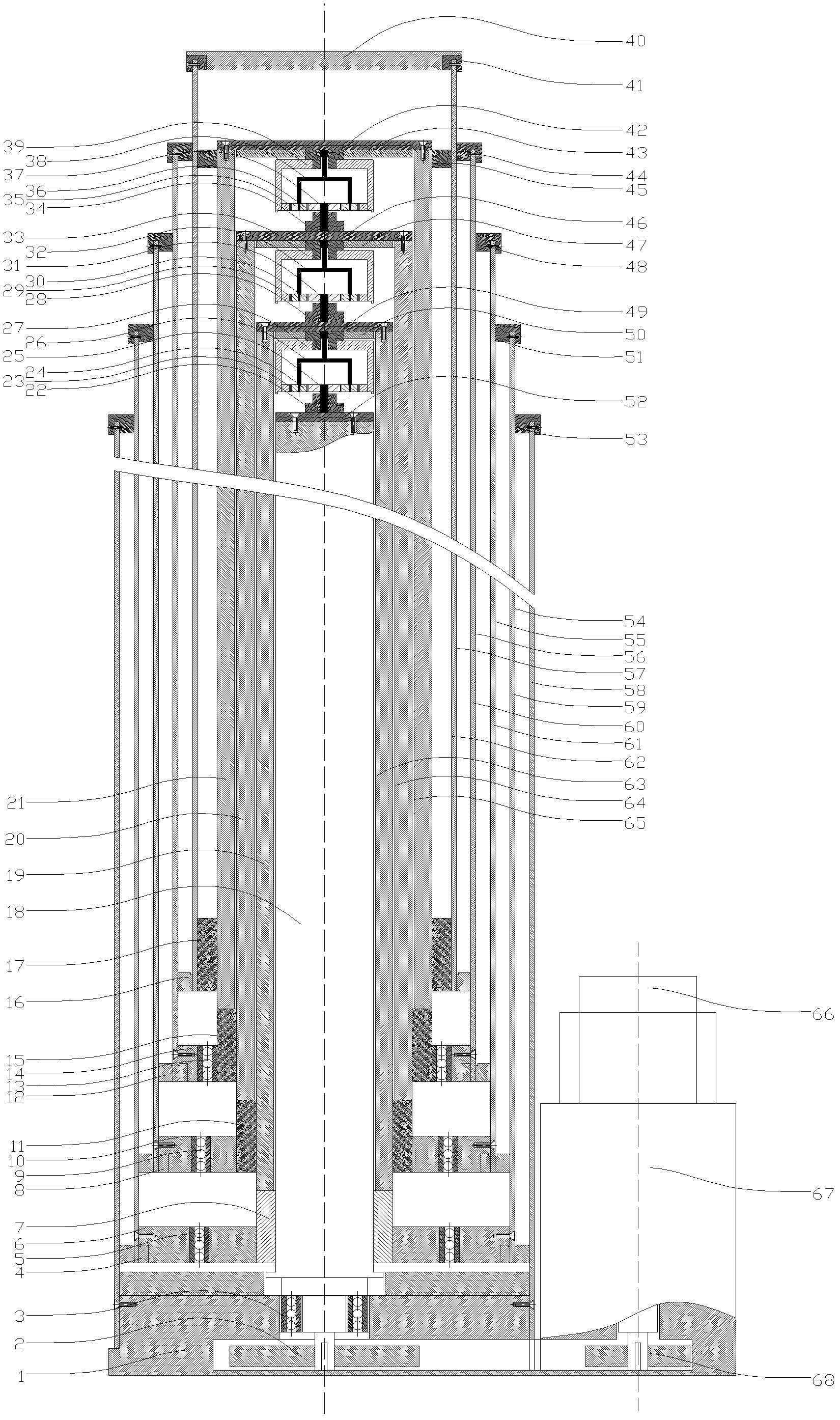

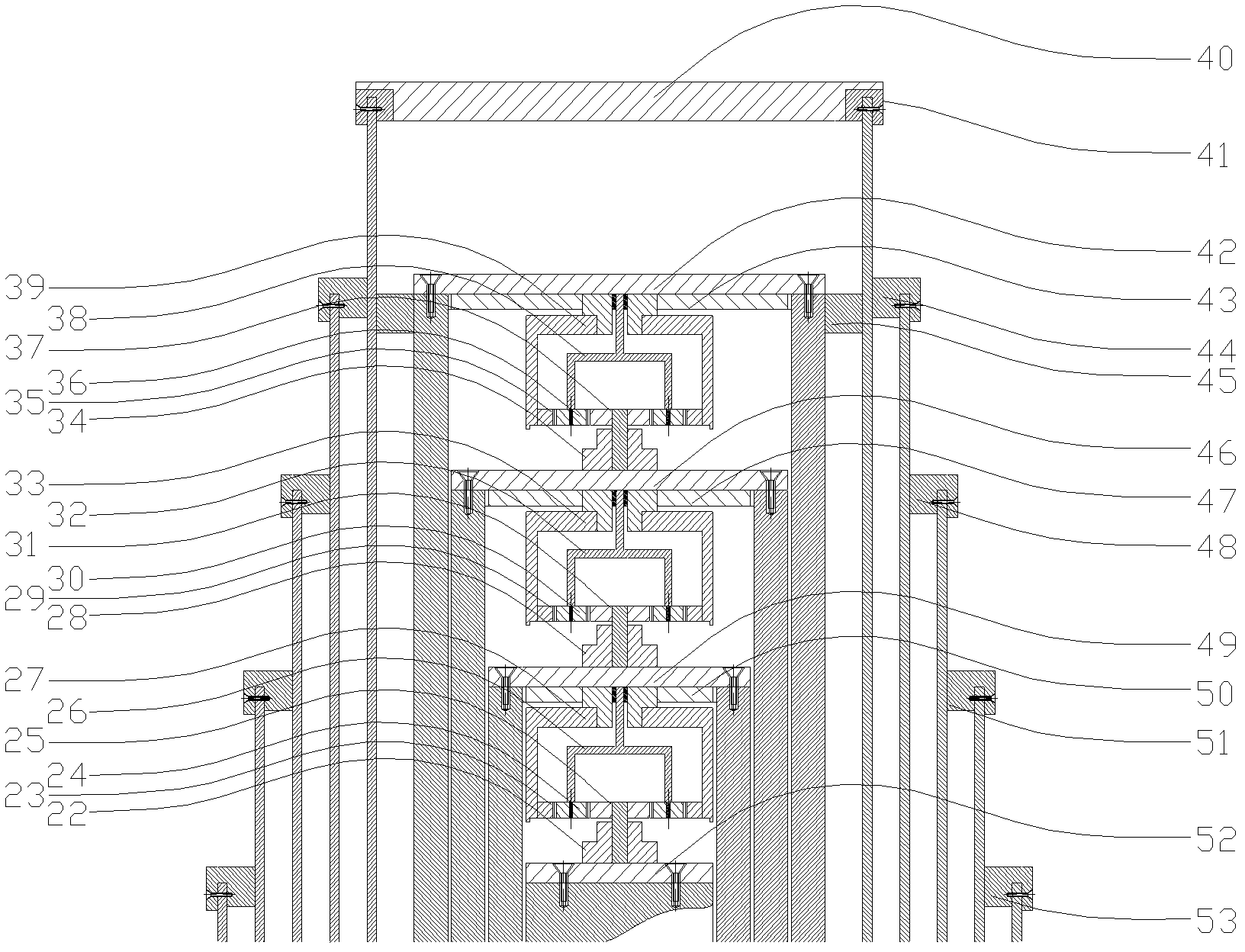

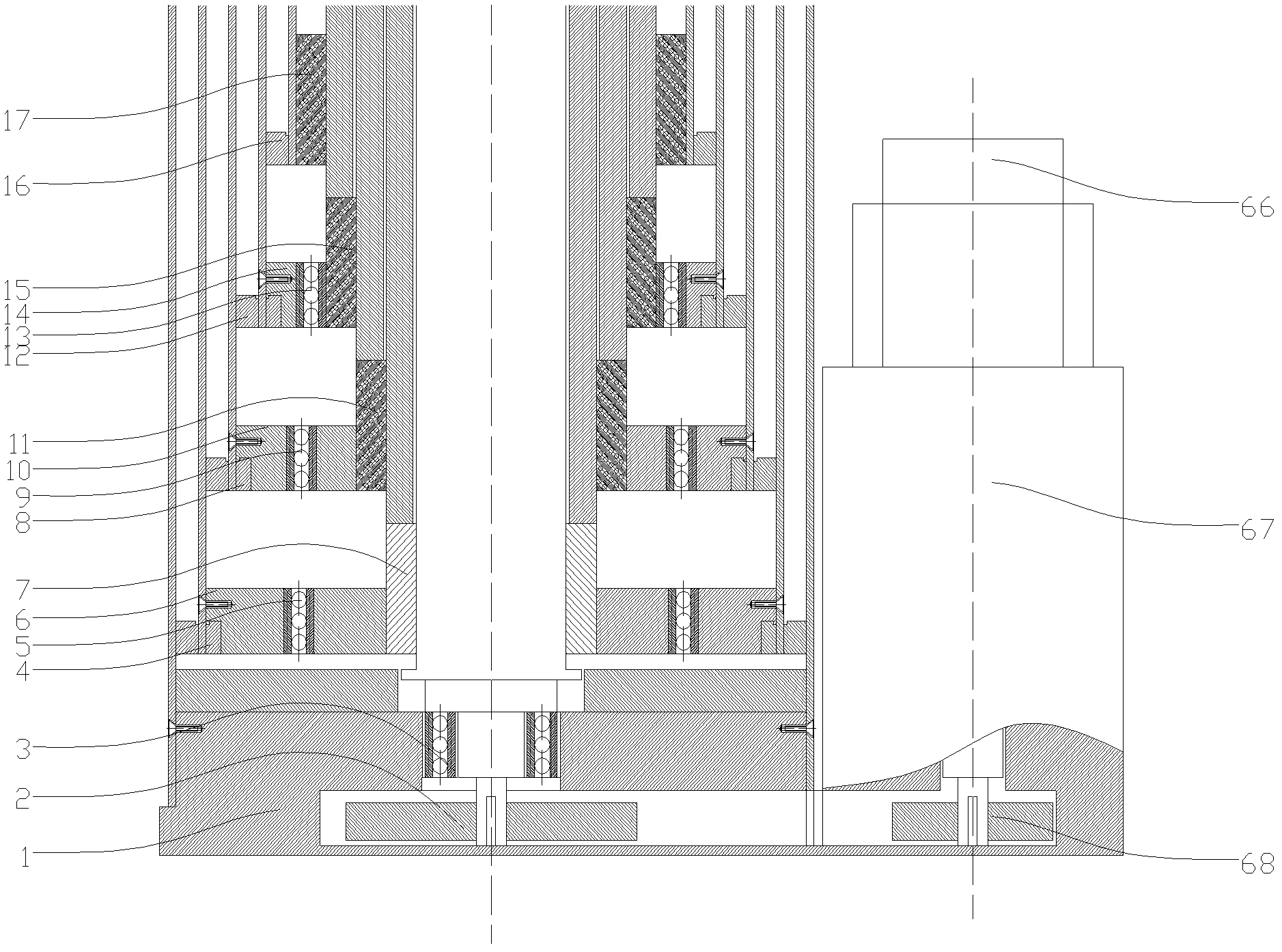

[0028] Such as Figure 1 to 6 As shown, when the mast needs to rise, the main drive motor 67 or the manual drive component 66 drives the reducer pinion 68 to rotate along the axis of the motor assembly, and the first sleeve 62 decelerates through a chain drive and drives the reducer gear 2 to drive the reducer The large gear 2 directly drives the primary screw 18 to rotate along the mast axis. Because the secondary screw 19 is rigidly connected to the secondary screw sliding screw pair 7, the secondary screw sliding screw pair 7 is The screw 18 is matched by the sliding screw, and the rotation of the primary screw 18 will cause the sliding screw pair 7 of the secondary screw and the secondary screw 19 to rise simultaneously. At the same time, the primary lead screw 18 and the secondary lead screw 19 are driven by the first drive main drive base 22, the first drive slave drive gear 23, the first drive planetary wheel 24, the first drive main drive gear 25, and the first drive pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com