Heat treatment technology after austenite shot-blast steel pipe cold deformation

An austenite and cold deformation technology, which is applied in the heat treatment process of power plant boiler steel pipes, can solve problems such as the impact of safe use of boiler materials and the disappearance of slip bands of shot peened steel pipes, and achieve the effect of maintaining steam oxidation resistance and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The composition of the alloy used in this example is shown in Table 1.

[0020] Table 1: Composition (Wt%) of austenitic stainless steel in Example 1.

[0021] C Si mn P S Ni 0.08 0.28 0.84 0.013 0.005 8.81 Cr Cu Nb N B Al 18.28 2.94 0.60 0.096 0.004 0.010

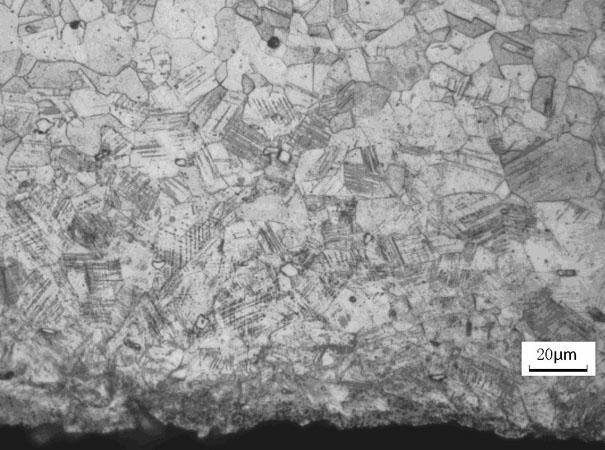

[0022] The metallographic structure of the inner wall of the steel pipe after shot peening is as follows figure 1 As shown, there are many slip bands and dislocation structures. After heat treatment in a heat treatment furnace up to 675°C, heat preservation for 10 hours, and air cooling, the metallographic phase of the inner wall of the steel pipe is as follows: figure 2 It can be seen from the figure that the austenitic shot-peened stainless steel tube still retains the slip band and dislocation structure. The metallographic structure map is obtained by taking a metallographic microscope, and the instrument model is Zeiss Axio observer.D1m.

Embodiment 2

[0024] The alloy composition used in this embodiment is shown in Table 2.

[0025] Table 2: Composition (Wt%) of austenitic stainless steel in Example 2.

[0026] C Si mn P S Ni 0.08 0.20 0.85 0.024 0.005 8.44 Cr Cu Nb N B Al 18.52 2.91 0.53 0.11 0.004 0.010

[0027] The metallographic structure of the inner wall of the steel pipe after shot peening is as follows image 3 As shown, there are many slip bands and dislocation structures. After heating up to 700°C in a heat treatment furnace, holding the heat for 2 hours, and air cooling, the metallographic phase of the inner wall of the steel pipe is as follows: Figure 4 It can be seen from the figure that the austenitic shot-peened stainless steel tube still retains the slip band and dislocation structure. The metallographic structure map is obtained by taking a metallographic microscope, and the instrument model is Zeiss Axio observer.D1m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com