Upper air anti-collision guardrail module transfer hanging bracket and construction method

An anti-collision guardrail and shifting formwork technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of slow construction progress, and achieve the effects of short construction period, high quality, and convenient dismantling and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

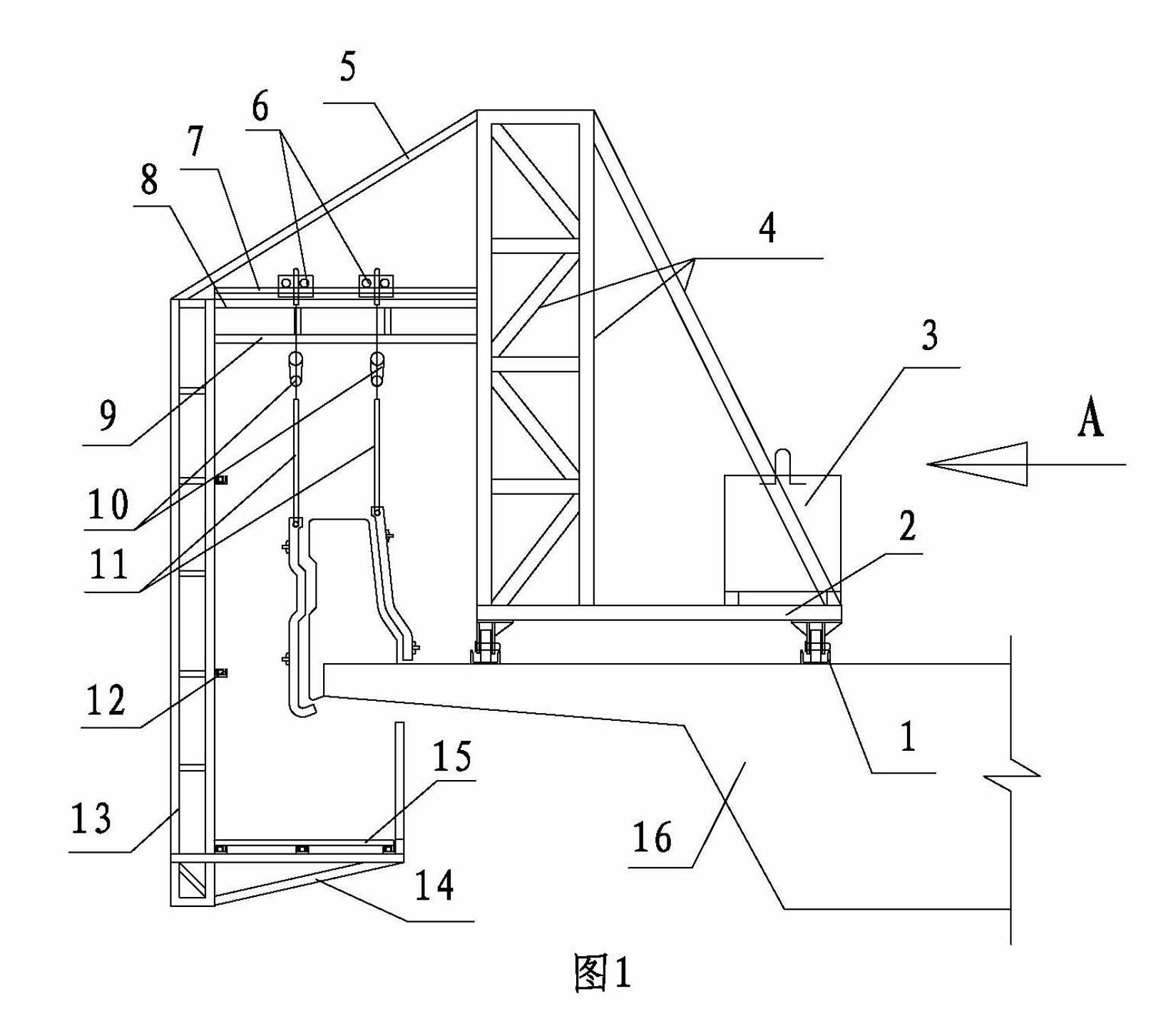

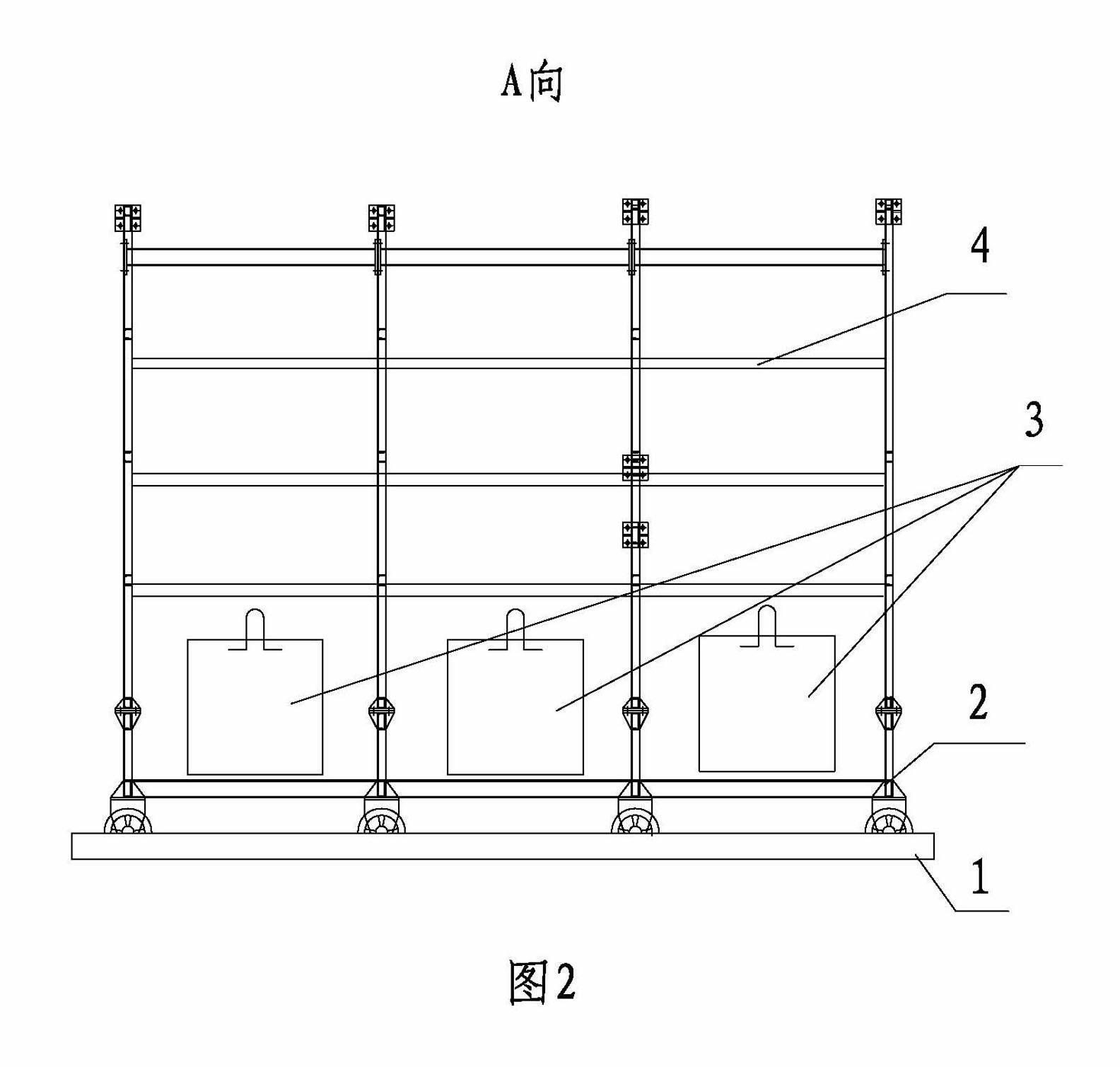

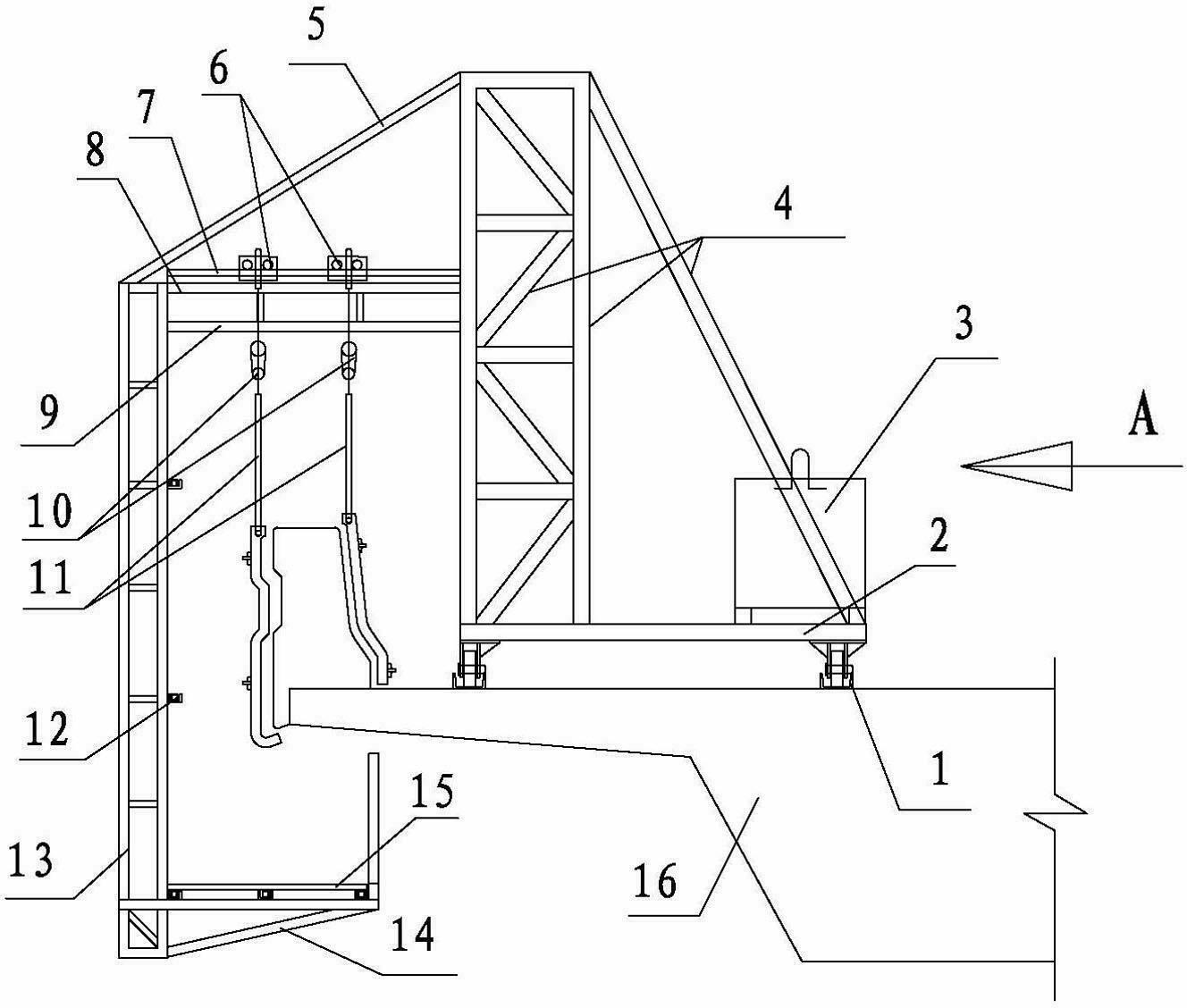

[0022] Such as figure 1 , figure 2 As shown, the high-altitude anti-collision guardrail formwork hanger of the present invention includes two slide rails 1 above the viaduct 16, a trolley 2 is provided on the slide rail 1, and a counterweight 3 and an inner truss 4 are provided on the trolley 2. There are several inner trusses 4 on the trolley 2 of the high-altitude anti-collision guardrail mold transfer hanger of the present invention. The tops of several inner trusses 4 are longitudinally connected by connecting rods 17 . The upper part of each inner truss 4 is connected to the outer truss 13 through the inclined beam 5 , the upper beam 8 and the lower beam 9 . A protective fence 12 is provided on the outer truss 13 . The lower part of the outer truss 13 is connected with a horizontal frame 14, and several horizontal frames 14 are longitudinally connected by pedals 15 to form a workbench. A slideway 7 is provided on the upper beam 8 . Two sliding bodies 6 are slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com