Automatic weighing system

A technology of automatic weighing and weighing device, applied in the field of weighing system and automatic control weighing system, can solve the problems of inconvenient query and post-tracking, cumbersome batch and weight, waste of labor cost, etc., and achieve the degree of automation High, easy to operate, saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

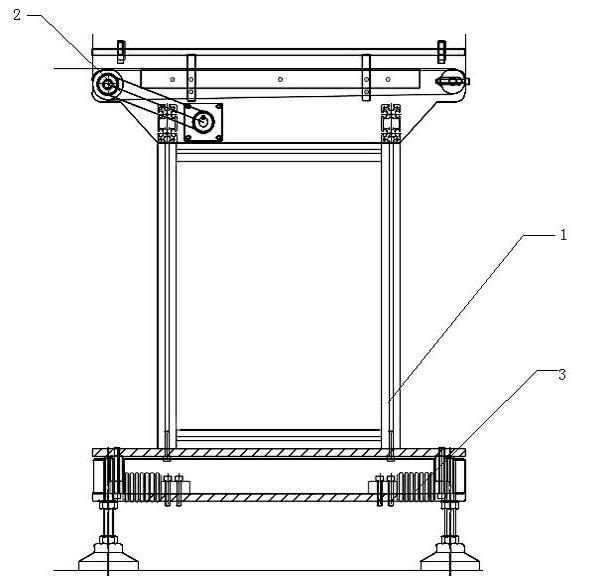

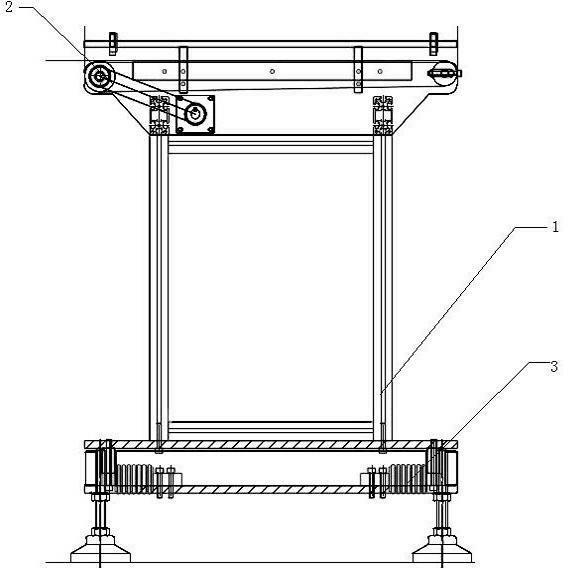

[0019] figure 1 It is the front view of the weighing device of the present invention;

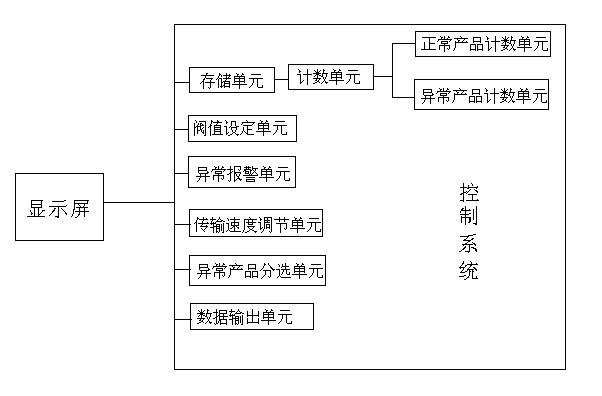

[0020] figure 2 It is a structural schematic diagram of the control device of the present invention.

[0021] Such as figure 1 and figure 2 Shown: an automatic weighing system, including a weighing device 1, a pressure sensor 3, a transmission device 2, a control device and a display screen, the transmission device 2 is arranged on the top of the weighing device 1, and the pressure sensor 3 is arranged at the bottom of the weighing device 2, and the pressure sensor 2 and the display screen are both connected to the control device, and the control device is provided with a control system.

[0022] In this embodiment, the weighing device 1 is made of aluminum alloy and SUS304 stainless steel, with a size of 600mm in length, 700mm in width, and 800...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com