Passive temperature sensor and test system based on same

A technology of temperature sensor and sensor, which is applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve problems such as line aging, limit the application of sensors and sensor systems, and system failure, and achieve accuracy improvement , to achieve the effect of passive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings in order to better understand the present invention. It should be particularly reminded that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

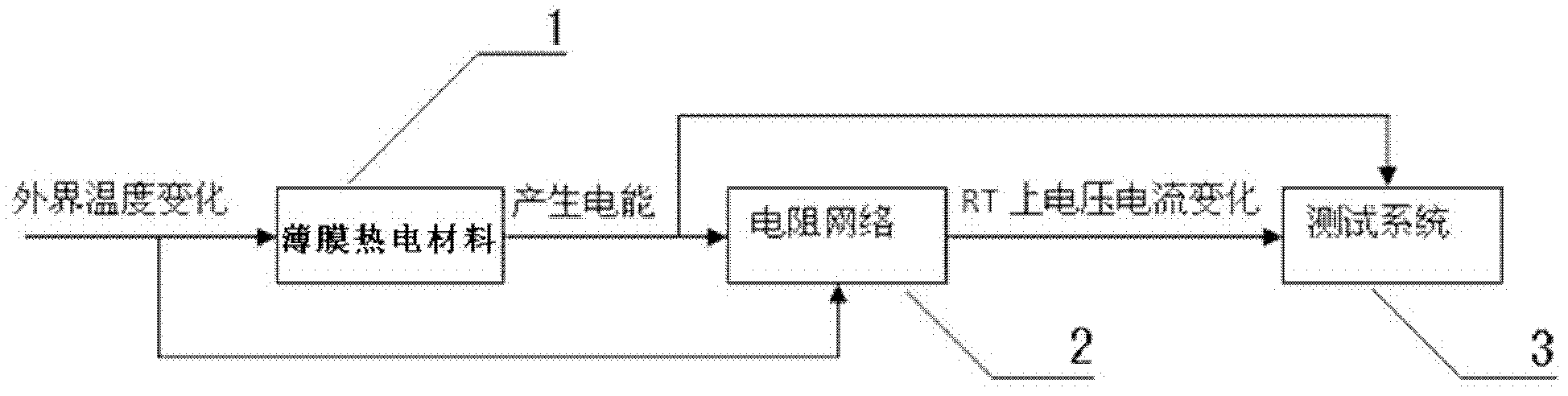

[0026] figure 1 Shown is a block diagram of a passive temperature sensor system. When the outside temperature changes, the thermoelectric material converts the change in the temperature field into electrical energy. The electrical energy generated will power the resistive voltage divider network and subsequent equipment. The back-end measurement circuit measures the resistance of the thermistor to obtain the current The temperature value.

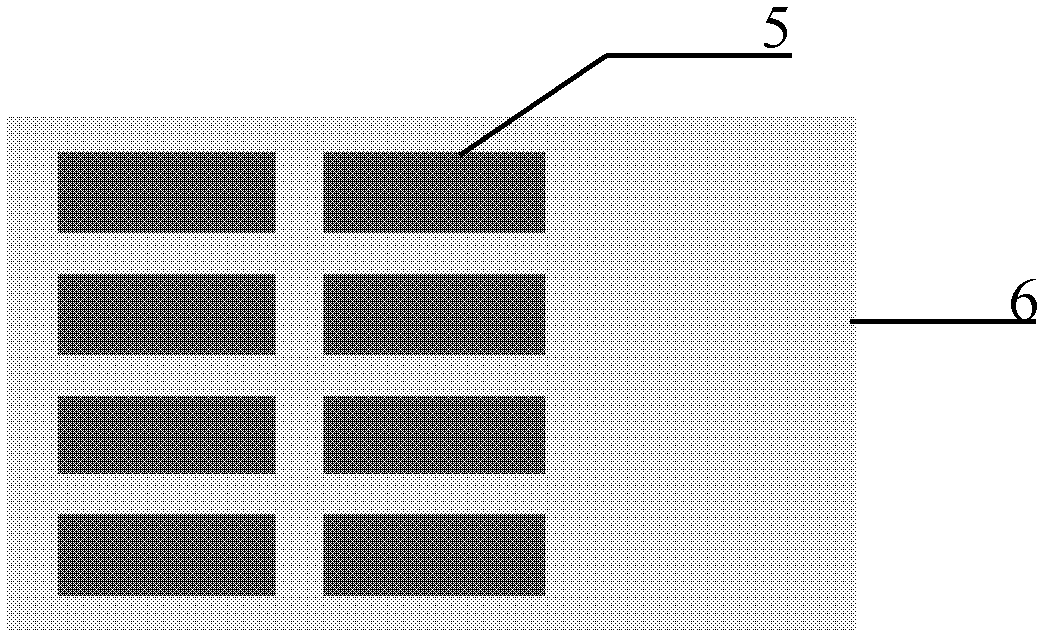

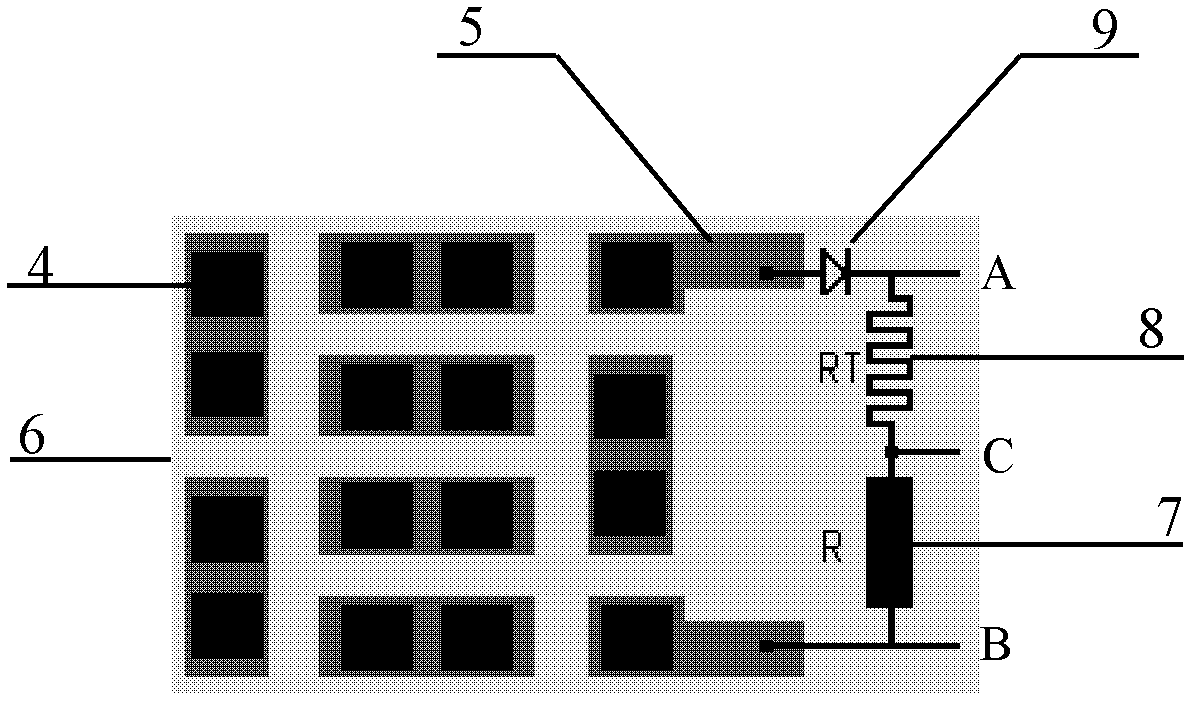

[0027] figure 2 Shown is the top view of the upper electrode plate of the passive temperature sensor. The electrode plate uses a 4cm*5cm (length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com