Drainage method for high-fall heavy-caliber oil-gas pipeline after pressure testing

An oil and gas pipeline, large-diameter technology, applied in the application of stable tension/pressure to test the strength of materials, by measuring the acceleration and deceleration rates of fluids, and using liquid/vacuum for liquid tightness measurement, etc. It can solve problems such as pipeline bursting , to achieve the effect of convenient operation, clear principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

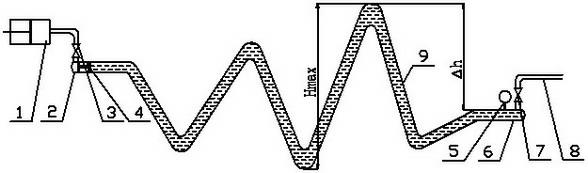

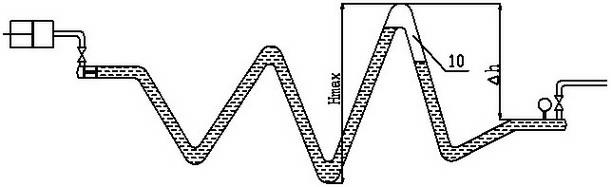

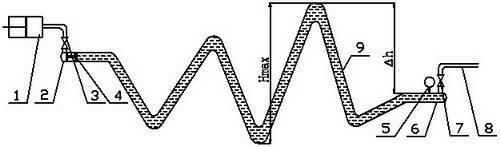

[0027] according to figure 1 As shown, the pipeline is laid in a high drop area, assuming that the maximum elevation difference in the pipeline is H max 100m, pipe outer diameter D It is 1219mm, the wall thickness is 18.4mm, and the construction site temperature is 20°C. Before the pressure test on the main line 9, install a pressure gauge 5 on the pressure test head A6 at the drain end, weld a branch pipe on the pressure test head A6 and install a high pressure gate valve A7, and install a drain on the outlet end of the high pressure gate valve A7. Pipe 8, and then weld a branch pipe to the pressure test head B2 at the other end of the main line 9 and install the high pressure gate valve B3. After the pressure test is completed, the high pressure gate valve A7 and the high pressure gate valve B3 are in a closed state.

[0028] Choose the air compressor 1 with appropriate displacement and rated discharge pressure, and the rated pressure of air compressor 1 P not lower than ,amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com