Dynamic frictional force testing system and dynamic frictional force testing method of pavement materials

A testing system and pavement material technology, applied in the direction of analyzing materials, force/torque/work measuring instruments, measuring devices, etc., can solve the problems of large deviation of test results, inability to carry out all-weather test results stability, etc., and achieve stable test results. Good performance and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

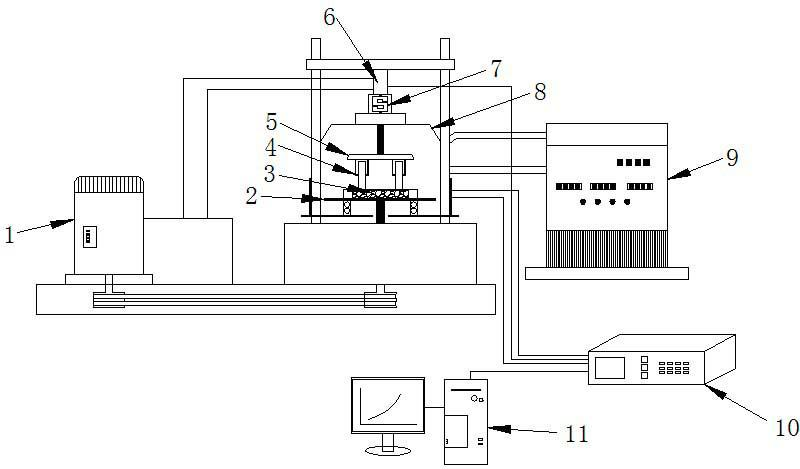

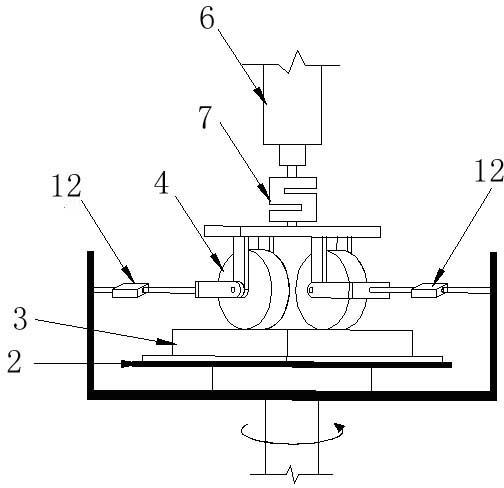

[0036] attached figure 1 It is a structural schematic diagram of the pavement material dynamic friction testing system of the present invention, with figure 2 It is a structural schematic diagram of the test part of the pavement material dynamic friction test system of the present invention, in which 1 is a frequency conversion motor, 2 is a rotating wheel platform, 3 is a tested pavement material, 4 is a test simulated tire, 5 is a loading bar, 6 is a Pressurizing piston, 7 is a pressure sensor, 8 is a heat preservation chamber, 9 is a temperature control device, 10 is a data acquisition instrument, 11 is a computer, and 12 is a tension sensor. As can be seen from the figure, the pavement material dynamic friction testing system of the present invention includes: a rotating system, a loading system, a temperature control system and a testing system; wherein,

[0037] The rotating system includes a frequency conversion motor, a frequency modulation controller and a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com