Connector with reinforced shielding shell

A technology of shielding shells and connectors, which is applied in the direction of connection, parts of connection devices, protective grounding/shielding devices of connection parts, etc. Problems such as electromagnetic interference of components and reduced working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

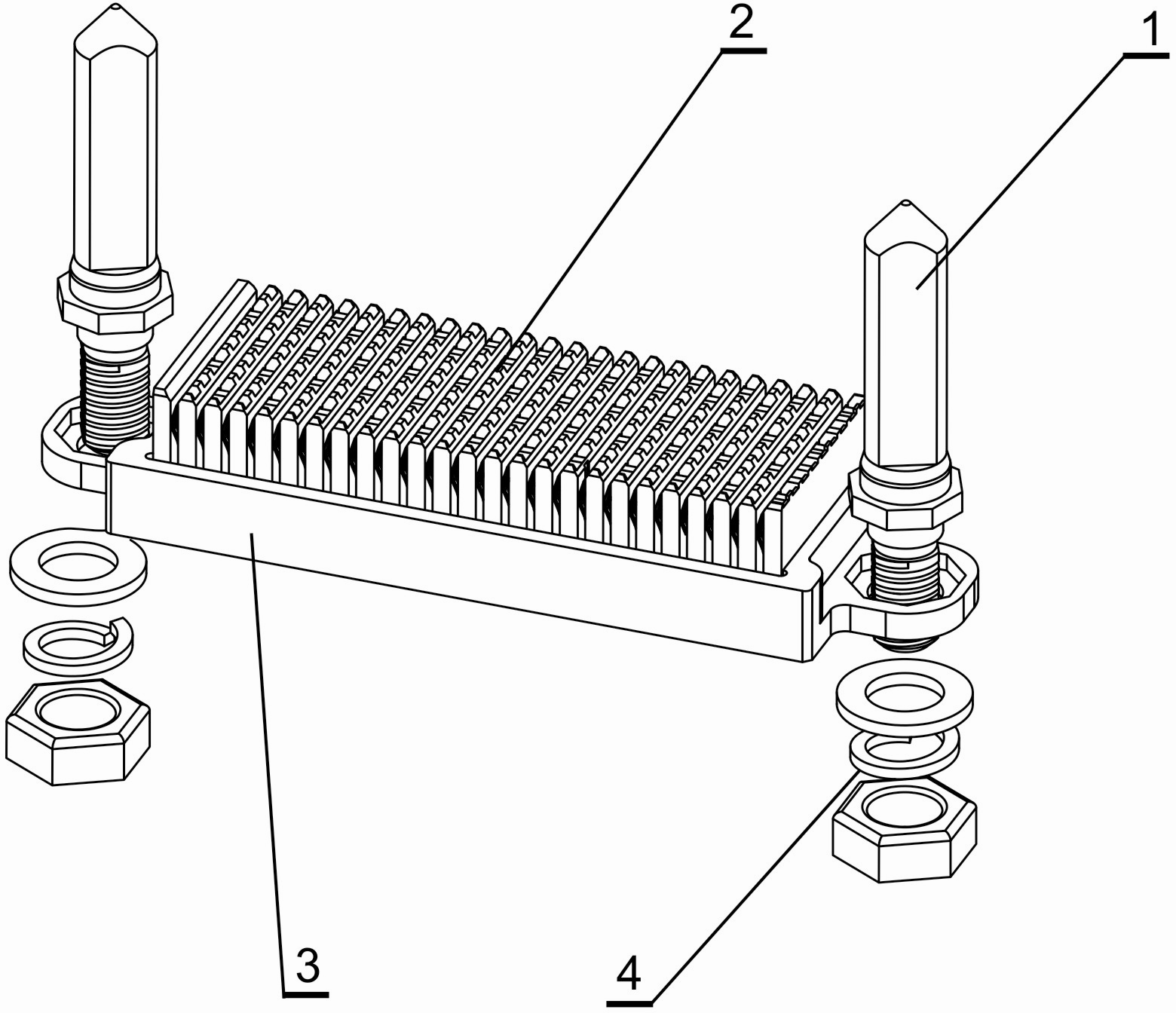

[0015] refer to figure 1 , the present invention includes a guide pin 1, a connector module 2, a housing 3 and a connector 4;

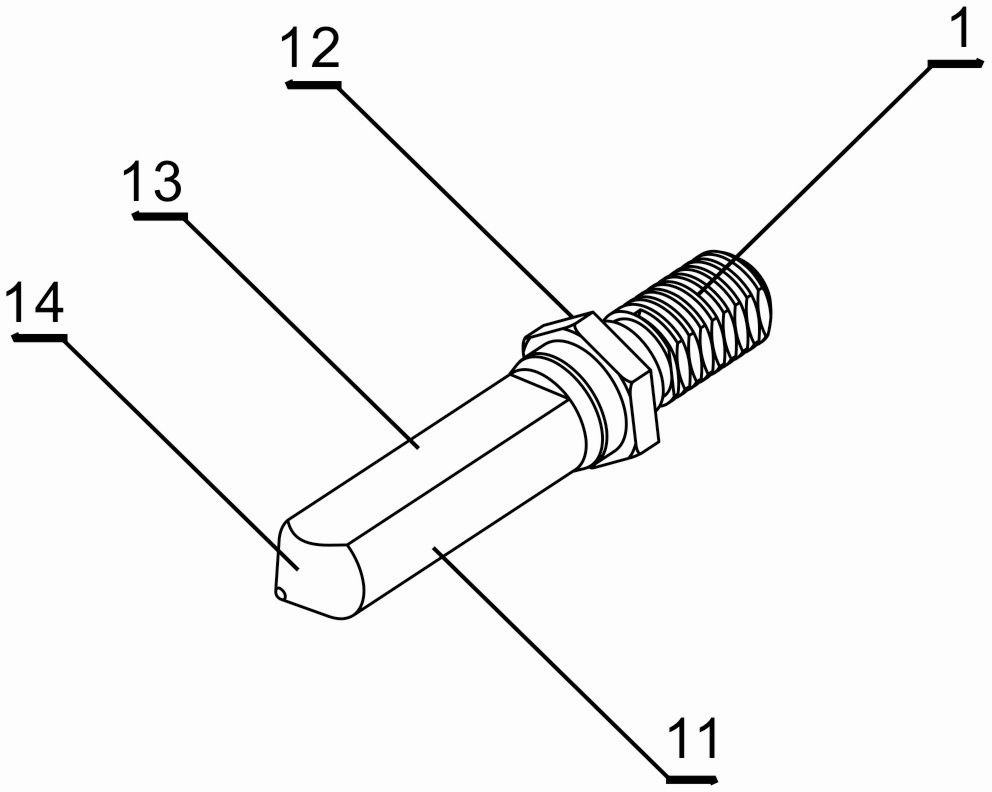

[0016] refer to figure 2 , the guide pin 1 is cylindrical formed by a polished rod 11 and a screw rod, wherein a step 12 is provided between the polished rod 11 and the screw rod, a plane 13 is provided on the cylindrical surface of the polished rod 11, and an arc surface 14 is provided at the end of the polished rod 11;

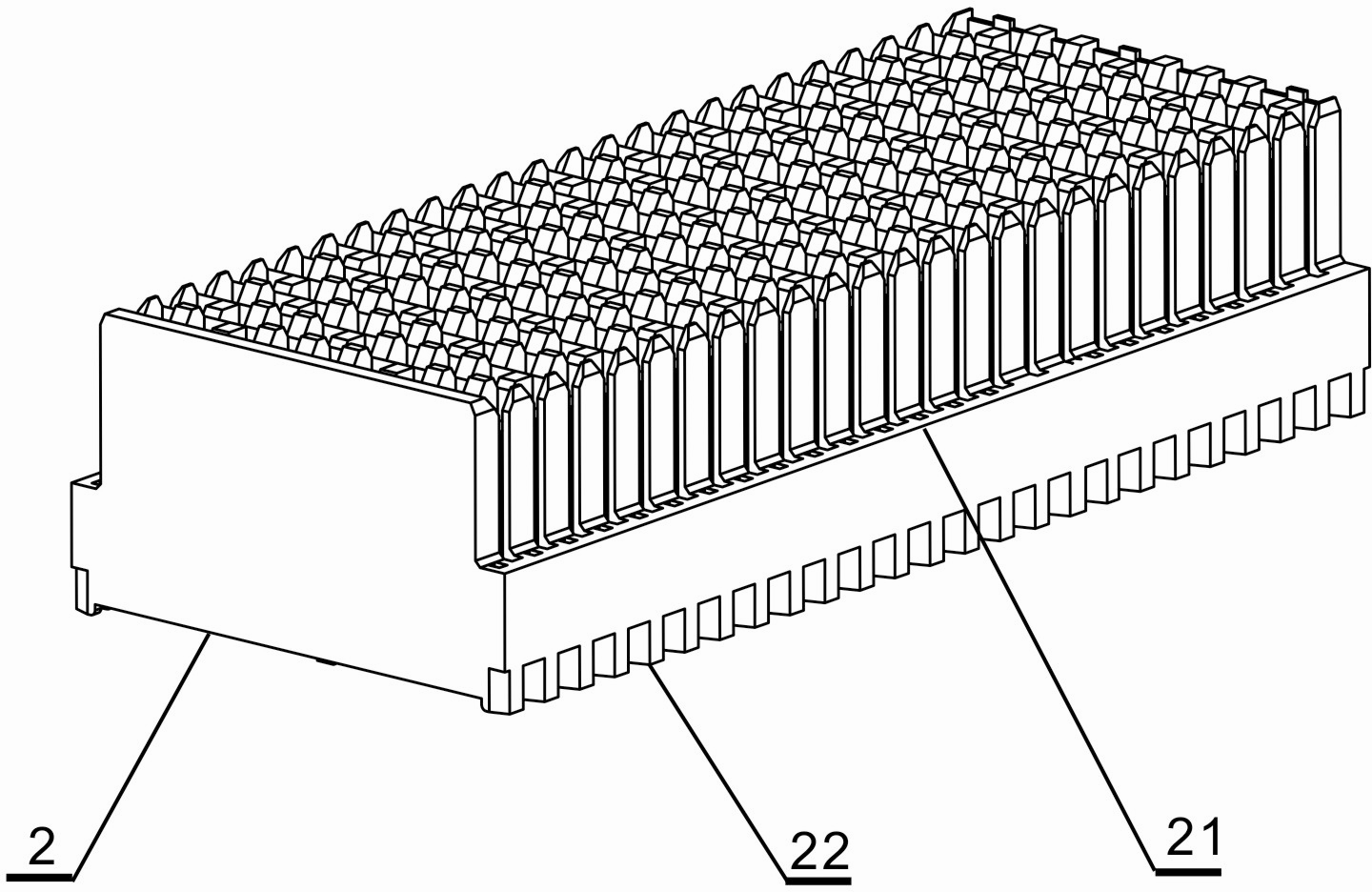

[0017] refer to image 3 , the connector module 2 is a rectangular block, with bosses 21 on both sides, and several grooves 22 parallel to the bottom of the bosses 21;

[0018] refer to Figure 4 , the housing 3 is a rectangular shape surrounded by four side walls, the upper edge of the symmetrical side walls is provided with ribs 31, the lower edge is provided with a row of convex hulls 32, and the outer ends of the remaining symmetrical side walls are provided with connecting The lifting lug 33 is provided with a step hole 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com