Digital intelligent slip ring

An intelligent, slip ring technology, applied in current collectors, electrical components, transmission systems, etc., can solve problems such as high cost, complex structure, and low reliability, and achieve the effect of reducing maintenance, cumbersome maintenance, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

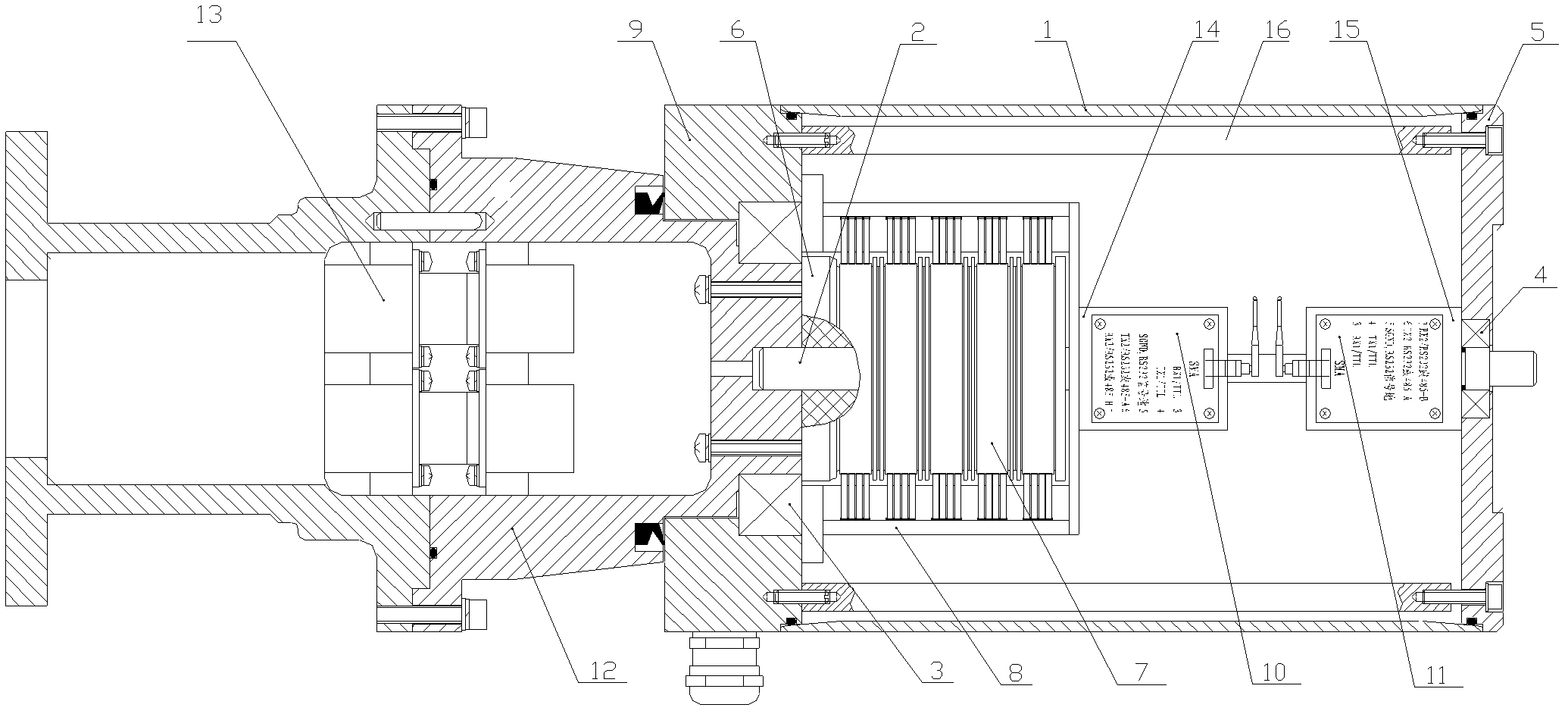

[0008] As shown in the drawings, the stator seat 9 fixes the rotor seat 12 through the bearing 3, and the electrical connector 13 is fixed inside the rotor seat 12. The left end of the rotating shaft 2 is fixed on the rotor seat 12 at the center of the bearing 3, and the right end of the rotating shaft 2 passes through the bearing. 4 is fixed with the end cover 5, and the end cover 5 and the stator seat 9 are fixedly connected by a tie rod 16, and the outer end cover 5 of the tie rod 16 and the stator seat 9 are sealed and fixed to the shell 1.

[0009] On the left side of the rotating shaft 2, an insulating annular column 6 is fixed, and a conductive ring 7 is fixed on the annular column 6, and the brush group 8 slidingly matched with the conductive ring 7 is fixed with the stator base 9.

[0010] The wireless rotary communication module 10 is fixed on the right side of the rotating shaft 2, the communication line of the wireless rotary communication module 10 is drawn through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com