Mint-doped tobacco baking and blending method

A technology of peppermint and flavoring, applied in directions such as tobacco, tobacco preparation, and tobacco treatment, can solve problems such as no successful reports, and achieve the effects of enriching the aroma of tobacco leaves, reducing usage, and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

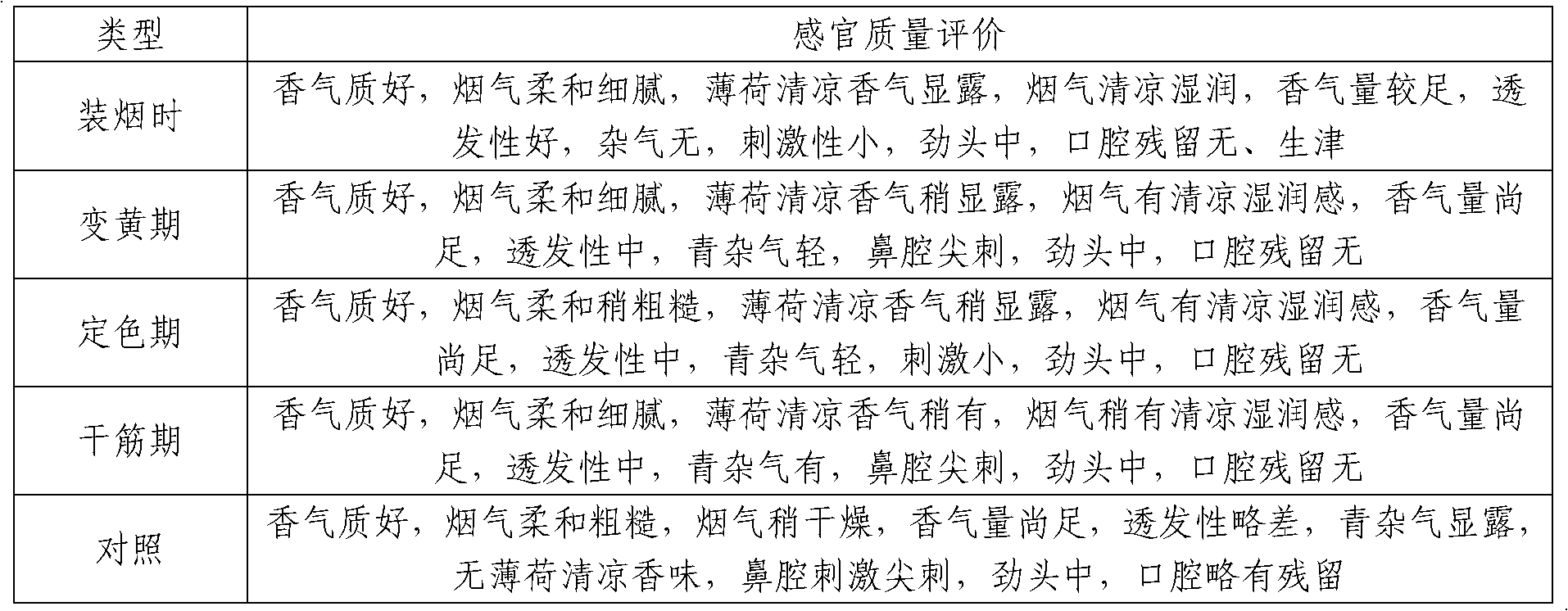

Embodiment 1

[0013] Weigh 1000g of mint and divide it into 6 bamboo baskets, hang it at a place 3-5cm away from the tobacco leaves on the bottom table, and prepare it by baking together with the tobacco leaves according to the conventional three-stage curing method of flue-cured tobacco. The curing room is an ordinary intensive curing room. The room capacity is about 7000kg / furnace. The effect of putting in the experiment in four stages: 1. When loading the tobacco, put it in the barn before lighting the fire; 2. During the yellowing period, bake for about 24 hours, when the temperature of the barn reaches 38°C 3. During the color-fixing period, bake for about 72 hours, and put it in the oven when the temperature of the oven reaches 50°C; 4. During the drying period, bake for about 96 hours, and when the temperature of the oven reaches 60°C Put it in the oven. After the curing, the tobacco leaves were taken out to make cigarettes, and compared with the tobacco leaves not added with mint, ...

Embodiment 2

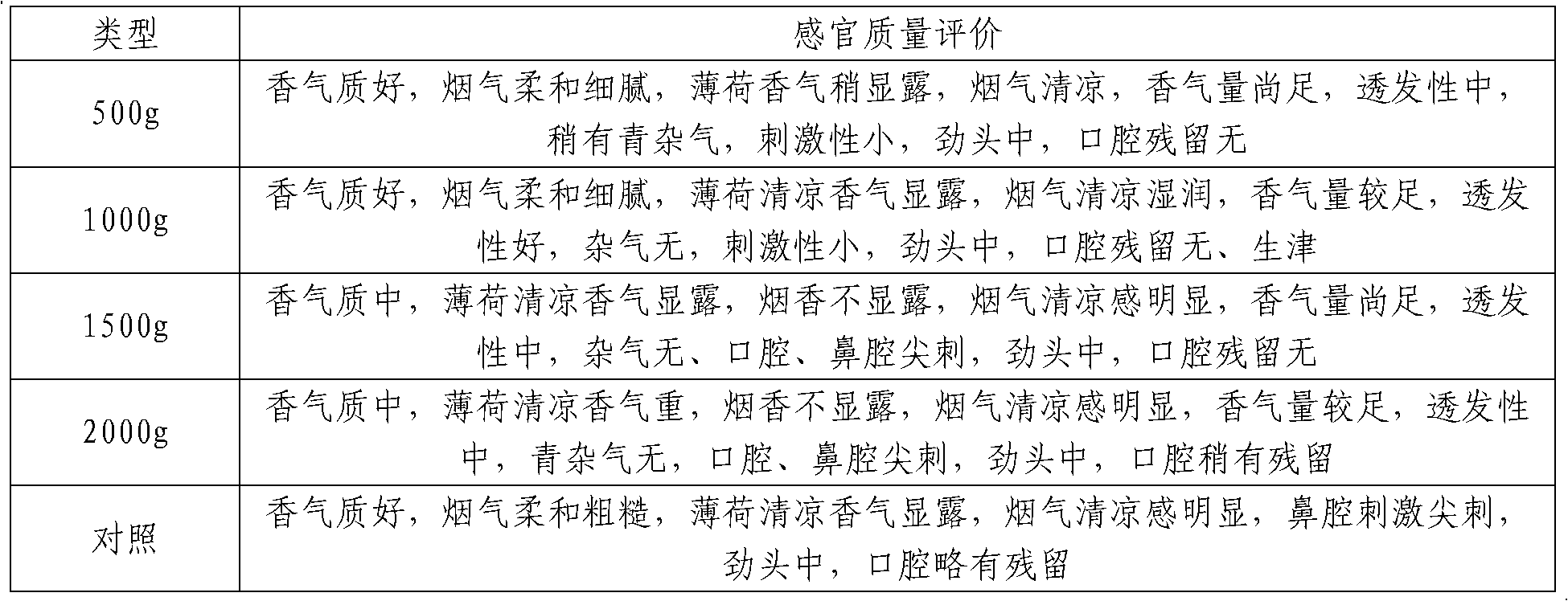

[0025] Weigh 500g, 1000g, 1500g, and 2000g of mint respectively, and put them into different curing rooms to be baked together with the tobacco leaves when filling the tobacco. The curing rooms are ordinary intensive curing rooms, and the capacity of the curing rooms is about 7000kg / furnace. Hang in the barn in a bamboo basket 3 to 5 cm away from the tobacco leaves on the bottom platform, and make cigarettes from the tobacco leaves taken out after the curing, and compare and smoke with the control tobacco leaves cured without mint material, and the results are as follows: See Table 4.

[0026] Table 4 Evaluation of sensory quality of tobacco leaf fragrance after adding different weights of mint when filling cigarettes

[0027]

[0028] The smoking evaluation shows that when the mint is added to the cigarettes, the aroma of the tobacco leaves is significantly improved when the amount of mint is from 500g to 1000g, and the smoke is full of cool breath of mint, making the arom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com