Machining process for slender shaft type part of unmachined outer circle

A processing technology and technology for shaft parts, which is applied in the field of processing technology for slender shaft parts without machining the outer circle, can solve problems such as inability to ensure uniform wall thickness, out-of-tolerance, and difficult calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

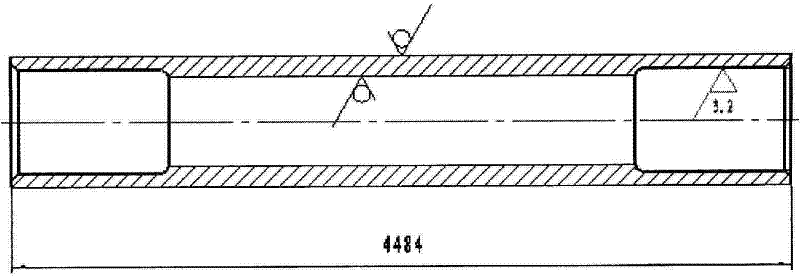

[0015] Such as figure 1 As shown, the length of a drawbar pipe fitting is 4484mm, and the dimensions, wall thickness, and straightness of the blank meet the technical requirements of the material, but because the part is too long, the blank cannot meet the machining requirements of the part, resulting in a fitter for each batch After correcting the outer circle with the welder, it takes a lot of man-hours to process the inner hole. At the same time, since the machining allowance of a single hole and one side is only 2.5mm, machining the outer circle can easily cause the wall thickness to be out of tolerance.

[0016] In order to improve production efficiency and ensure the machining accuracy of parts holes, and avoid out-of-tolerance, the processing technology of slender shaft parts with no outer circle processing is adopted, including the following steps:

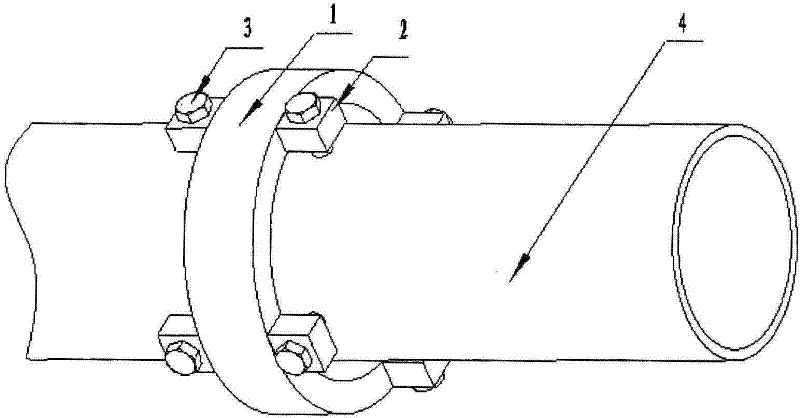

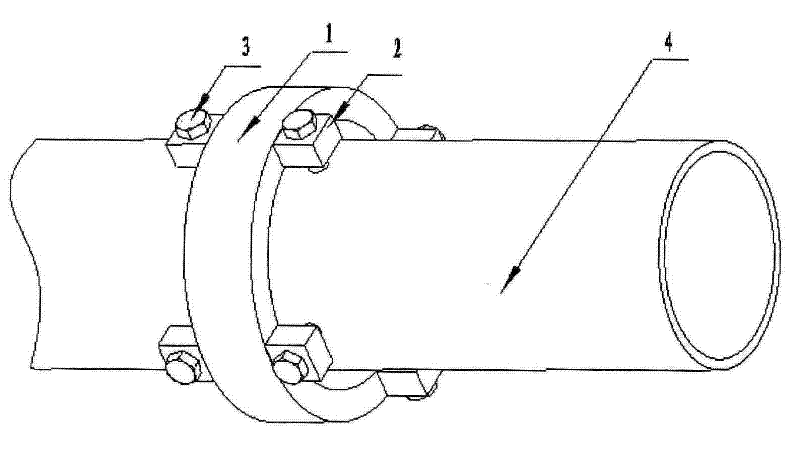

[0017] 1) Process an adjustable clamp, such as figure 2 As shown, its structure is as follows: the main body of the cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com