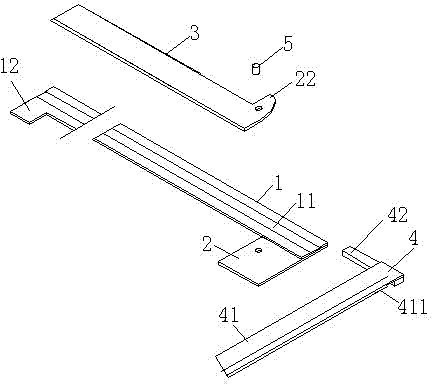

Grid marking tool

A scribing tool and grid technology, applied in manufacturing tools, workshop equipment, etc., can solve problems such as rework, inaccurate positioning and scribing, and missing documents, to eliminate scribing errors, accurate and consistent grid lines, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

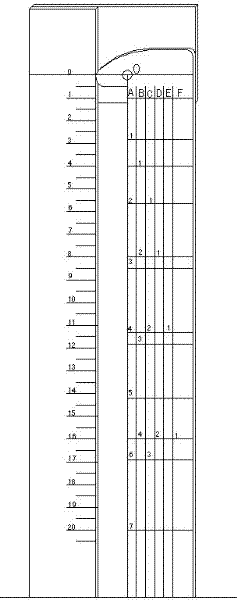

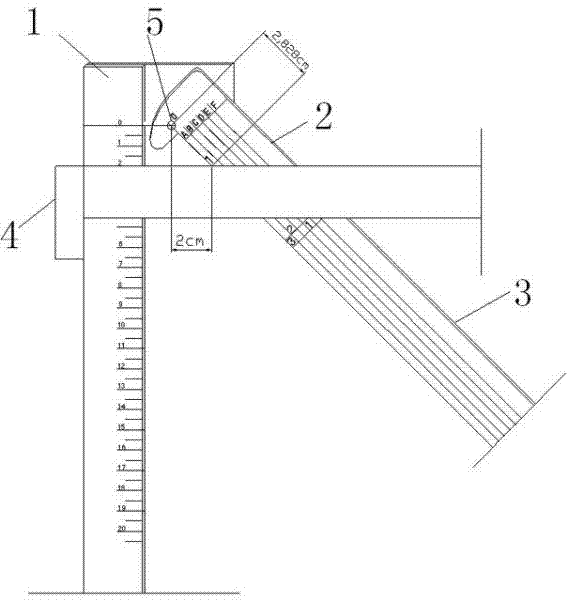

[0107] Embodiment 1, the dashed line of the equidistant grid line: determine that the grid line interval data is 2.49cm;

[0108] Rotate the angle positioning ruler 3 to the starting angle position;

[0109] According to the given grid line interval data of 2.49cm, move the position of the vernier 4 on the standard board ruler 1, so that the upper edge of the horizontal ruler 41 of the moving vernier ruler 4 is aligned with the data scale 2.49cm on the standard board ruler 1;

[0110] Observe the position of the line along the horizontal ruler 41 of the compass 4 on the angle positioning ruler 3; virtualize the overlapping line of the upper edge of the horizontal ruler 41 on the angle positioning ruler 3 as a reference line R, observe the location line on the angle positioning ruler 3 scale;

[0111] Lock the position of the vernier 4, take the virtual reference line R on the angle positioning ruler 3 as a reference, and the nearest scale below the reference line...

Embodiment 2

[0115] Embodiment 2, evenly divide the grid in the given line range:

[0116] Rotate the angle positioning ruler 3 to the starting angle position;

[0117] Given that the vertical line range is within 30 cm, the number of divisions is determined to be 10;

[0118] Align the starting point 0 of the standard board ruler 1 with the upper edge of the given vertical line range;

[0119] Move the vernier 4 at the position of the standard board ruler 1; move the upper edge of the horizontal ruler 41 of the movable vernier 4 to 30 cm from the lower edge of the given scribe range;

[0120] Observe the position of the line along the horizontal ruler 41 of the vernier 4 on the angle positioning ruler 3; virtualize the overlapping line of the upper edge of the horizontal ruler 41 on the angle positioning ruler 3 as a reference line R;

[0121] Lock the position of the vernier 4, and then turn the angle positioning ruler 3 counterclockwise until the position line with the nearest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com