Automatic fixed-length cutting machine for soft rubber hose

An automatic length-fixing and soft rubber hose technology, which is applied in metal processing and other directions, can solve the problems of manufacturers such as economic losses, large specification and size errors, and difficulty in precise lengthening, so as to improve corporate profits, reduce manufacturing costs, and avoid economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

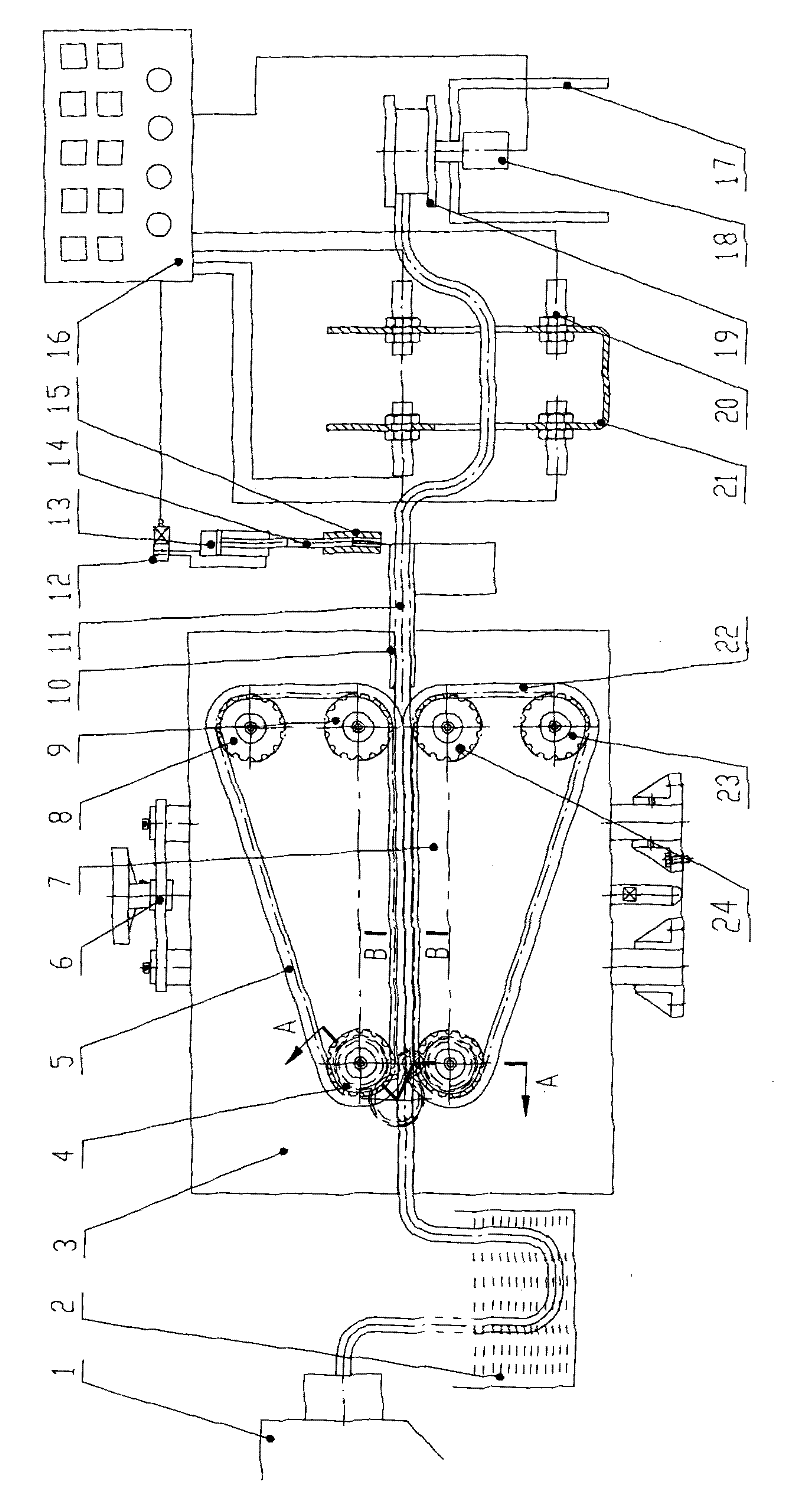

[0026] Depend on figure 1 It can be seen that the automatic fixed-length cutting machine for soft rubber hoses of the present invention includes an adjustment part 6, a transmission part 4, a quick cutting part, a coiling part, and a control part; wherein: the transmission part 4, the rapid cutting part, and the control part are two pairs of shooting tubes in the control part. 20 and the reel part are arranged in sequence along the forward movement direction of the soft rubber hose 11 . The structure of each component is described in detail below:

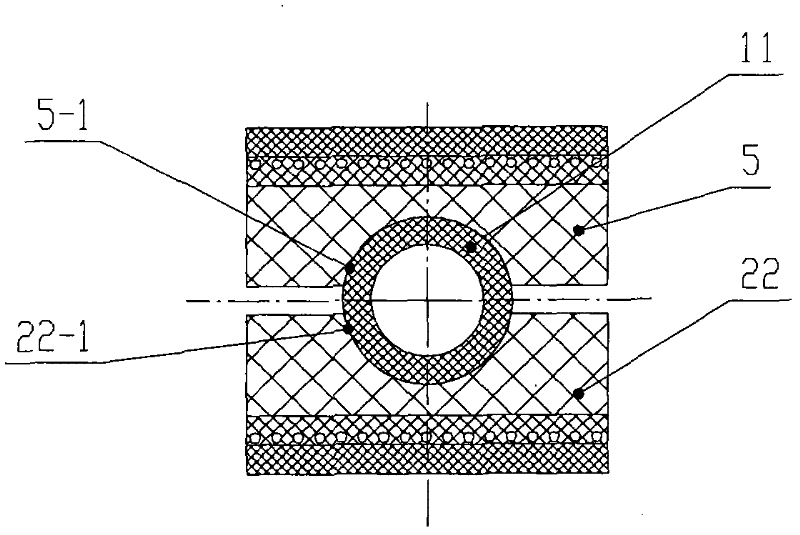

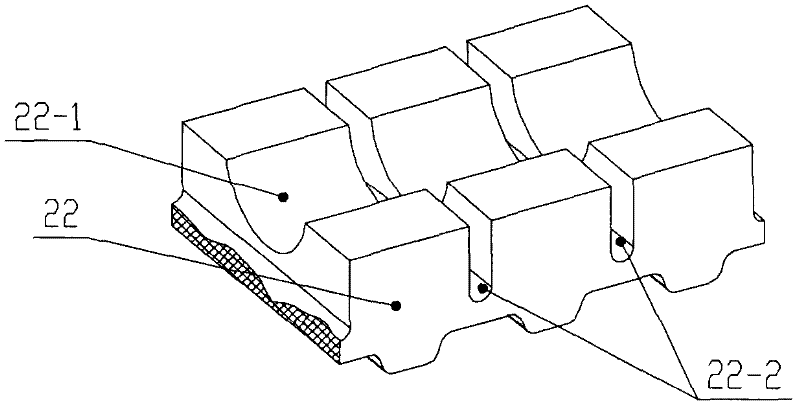

[0027] (1) Adjustment part: refer to figure 1 , Figure 4 .

[0028] The adjustment part is set for different diameters of soft rubber hoses, which can adjust the matching gap between a pair of special timing belts to meet the cutting needs of different diameters of soft rubber hoses.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com