Circulating spray washing system for anilox roll of intaglio printing press

A cleaning system and cycle injection technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of missing cleaning, low efficiency, and high cost of use, and achieve the effect of improving the cleaning effect and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

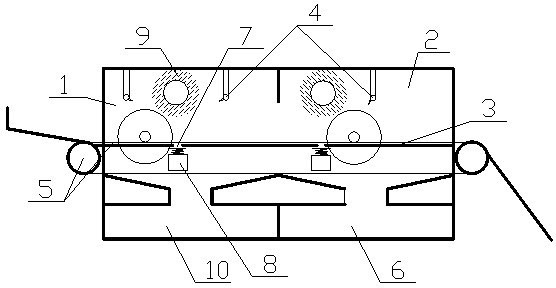

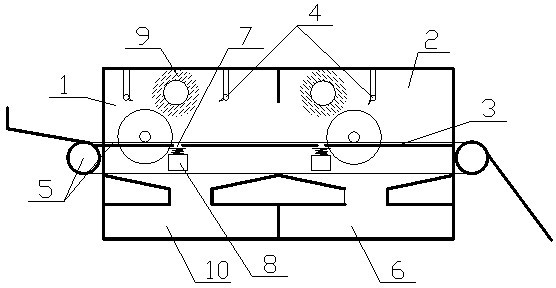

[0013] Embodiment 1: as figure 1 As shown in Figure 2, the cleaning room can be built with transparent tempered glass, which is divided into a preliminary cleaning room 1 and a fine cleaning room 2, and a waste solvent storage tank 10 and a solvent storage tank 10 are respectively arranged below the preliminary cleaning room 1 and the fine cleaning room 2. Recovery tank 6, the solution in the rough cleaning chamber is collected and processed. The solvent recovery tank 6 is connected with the solution extraction tank of the high-pressure pump, which can realize recycling and be replaced after cleaning for a certain period of time. The high-pressure pump used is an anti-static high-pressure pump.

[0014] A plurality of high-pressure nozzles 4 are arranged in the initial cleaning chamber 1 and the fine cleaning chamber 2, and the high-pressure pump is connected to the high-pressure nozzles 4; an anilox roller running track 3 is arranged in the cleaning room, and the anilox roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com