Oilfield skid block hoisting structure

A skid block and hoisting technology is applied in the field of oil field skid block hoisting structures, which can solve the problems of inapplicable skid block hoisting, affect the skid block space layout, occupy the skid block space, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

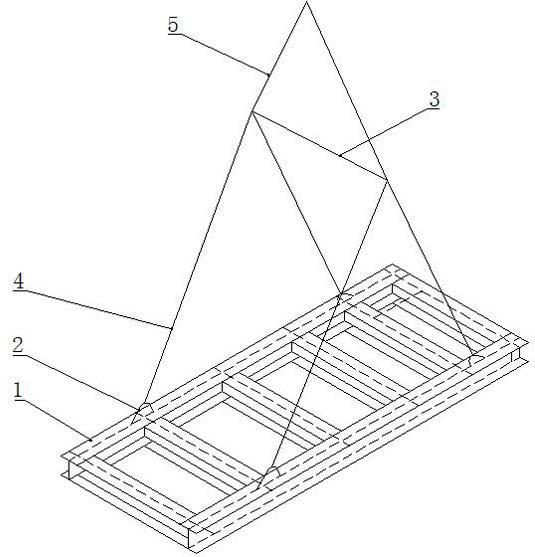

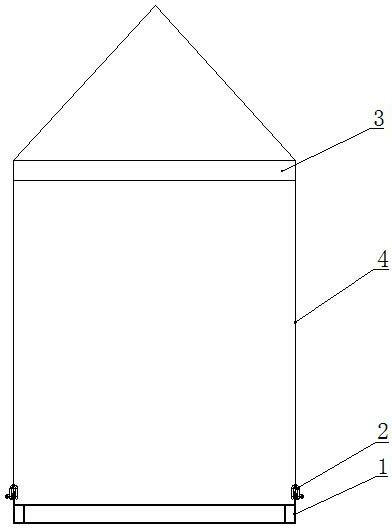

[0017] Such as figure 1 As shown, it includes a skid block 1, a lifting lug 2, a hanging beam 3, a sub-sling 4, and a main sling 5.

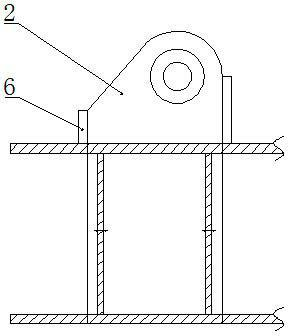

[0018] Two lifting lugs 2 are respectively arranged on the two sides of the above-mentioned skid block 1, and the lifting lugs 2 on the two sides are arranged symmetrically. In this embodiment, the two sides on which the lifting lug 2 is set are the long axis sides, and are located on the structural beam where the saddle of the large equipment on the skid is located.

[0019] Above the skid block 1, a hoisting system connected to the lifting lug is arranged, and the hoisting system at least includes a hoisting beam 3 and a subsling 4.

[0020] Specifically: the suspension beam 3 is horizontally arranged directly above the skid block 1, the axis of the suspension beam 3 is perpendicular to the long axis side of the skid block 1, and its length is equal to the distance between the two long axis sides of the skid block 1.

[0021] The number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com