Manual lifting trolley for forking and lifting

A manual and fork lifting technology, applied in the direction of lifting devices, can solve the problems of inconvenient, expensive and unsafe stacking, and achieve the effect of expanding the lifting height, cheap and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

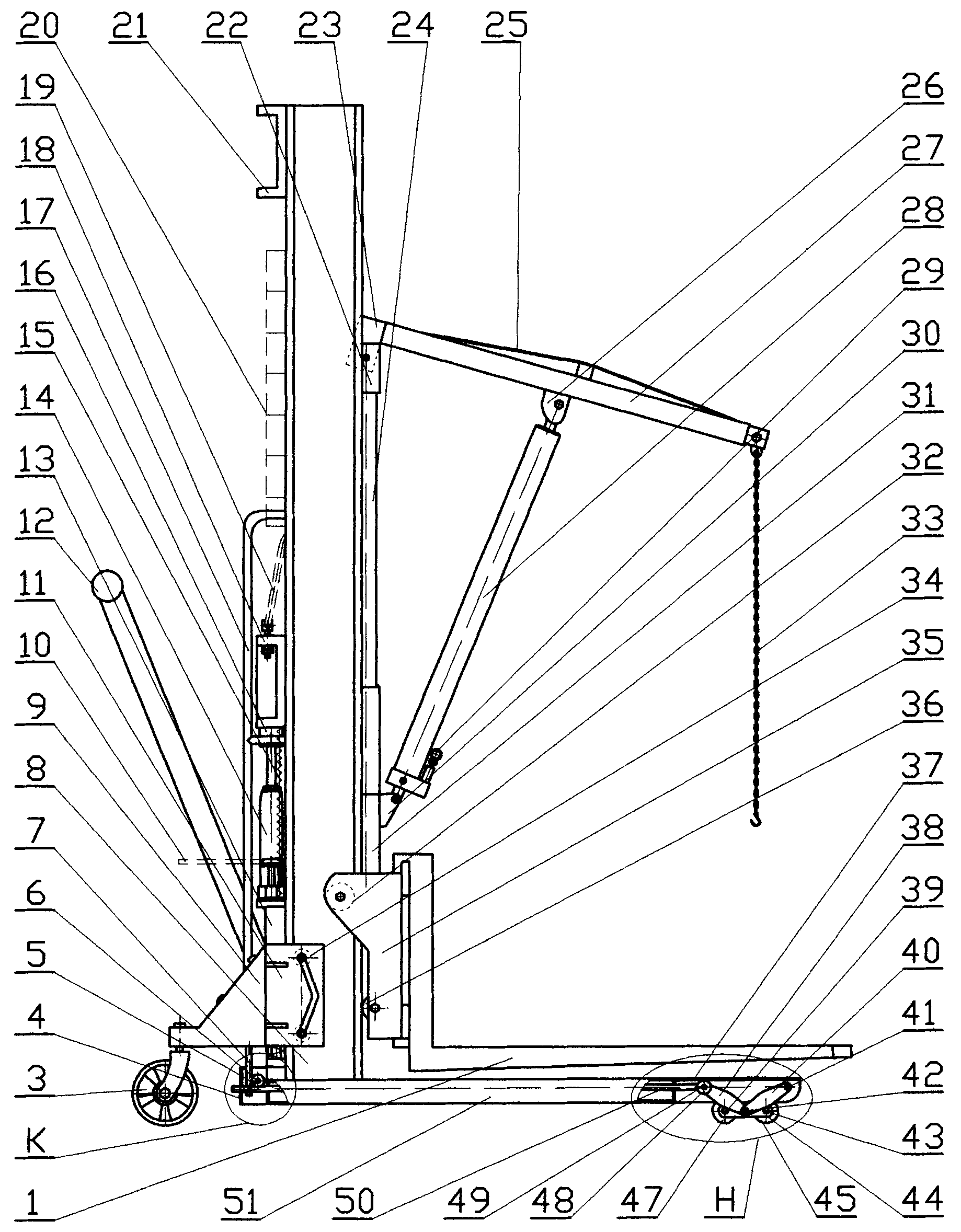

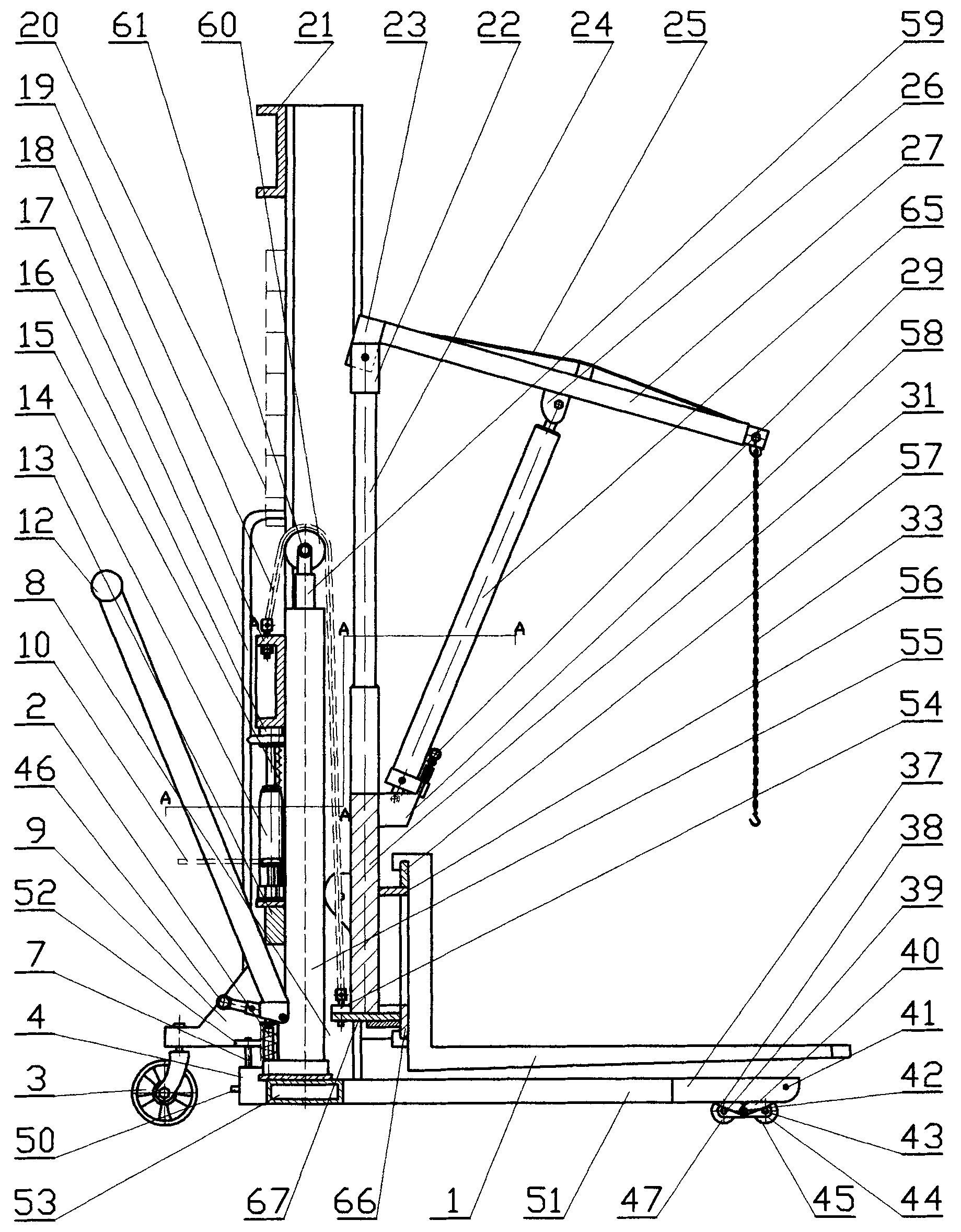

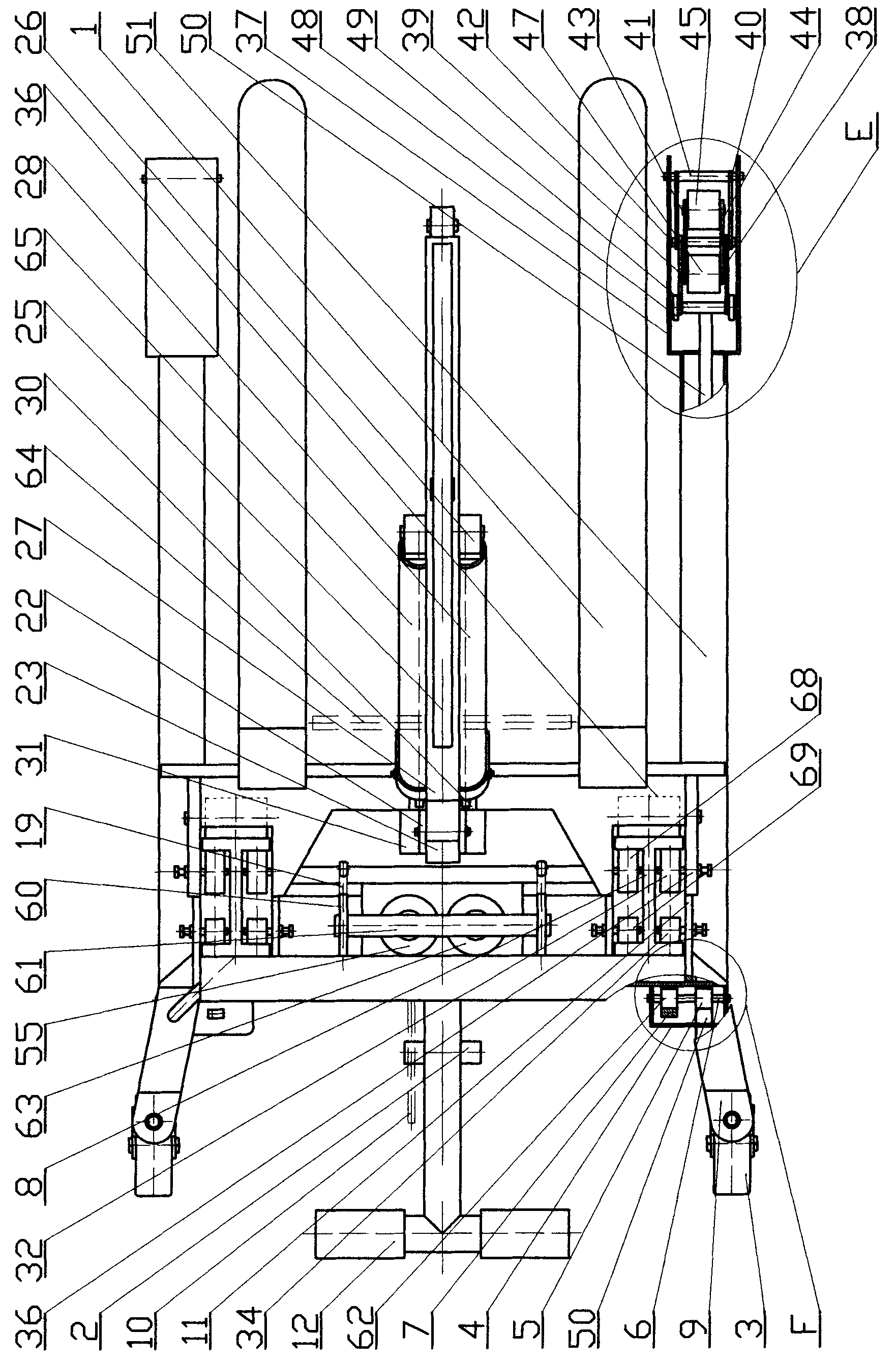

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0028] The present embodiment includes a pair of I-shaped lifting beam columns 8, a vehicle frame member, a fork lifting member and a lifting member, and a caster lifting member composed of a pair of directional casters, a caster lifting unit and a caster lifting conversion device.

[0029] The frame components include a frame beam 53 and a pair of frame longitudinal beams 51 with movable casters 3, a pair of frame longitudinal beams 51 are respectively installed at both ends of the frame beam 53, a pair of I-shaped lifting beam columns 8 and the lifting and lowering member device are on the vehicle frame beam 53. Also directional caster is housed at the front end of vehicle frame longitudinal beam 51, the rear portion device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com