Double-stage lifting type crawler pump truck

A lifting and crawler technology, which is applied in the field of double-stage lifting crawler pump trucks, can solve the problems of low space utilization rate, height increase, influence of vehicle driving stability, etc., and achieve the effect of improving space utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

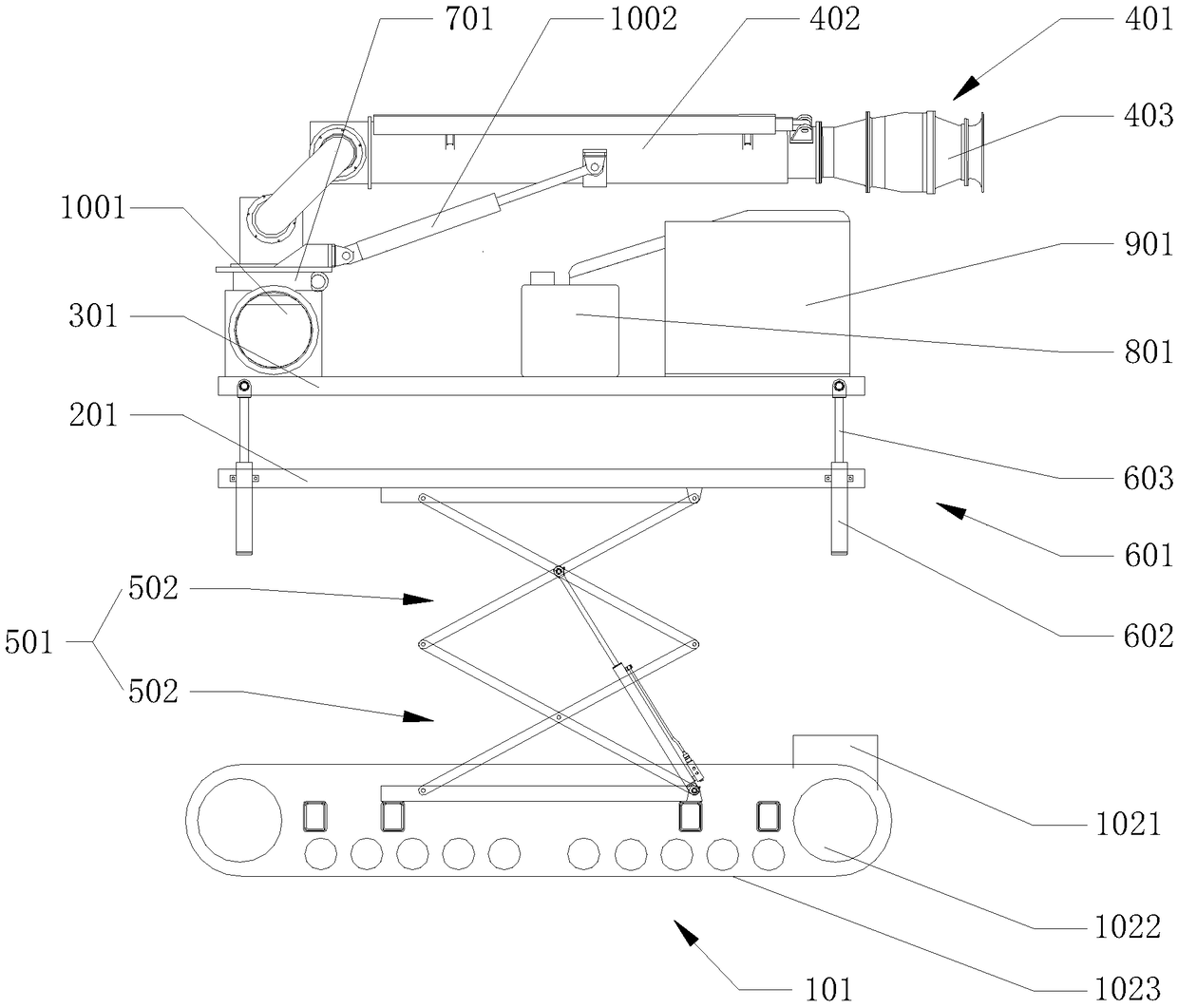

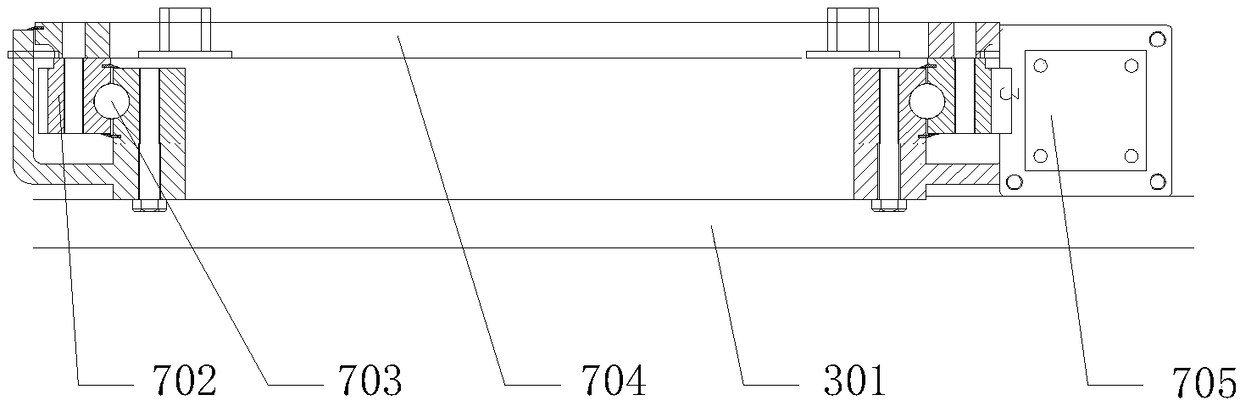

[0045] Please also refer to figure 1 as well as image 3, this embodiment discloses a two-stage lifting type crawler pump vehicle, the two-stage lifting type crawler pump vehicle includes a crawler chassis 101, a first carrying platform 201, a second carrying platform 301, a drainage mechanism 401, and a scissor lifting mechanism 501 , the first lifting rod 601 , the horizontal rotation device 701 , the hydraulic station 801 , the engine 901 and the drainage box 1001 . The first carrying platform 201 is arranged on the top of the crawler chassis 101, the second carrying platform 301 is arranged on the top of the first carrying platform 201, the scissor lift mechanism 501 includes the scissor arm unit 502 and the fourth telescopic rod 503, the scissors The arm unit 502 includes a first scissor arm 5021 and a second scissor arm 5022. The first scissor arm 5021 and the second scissor arm 5022 are arranged alternately. Orientation settings. In the adjacent two groups of scissor...

Embodiment 2

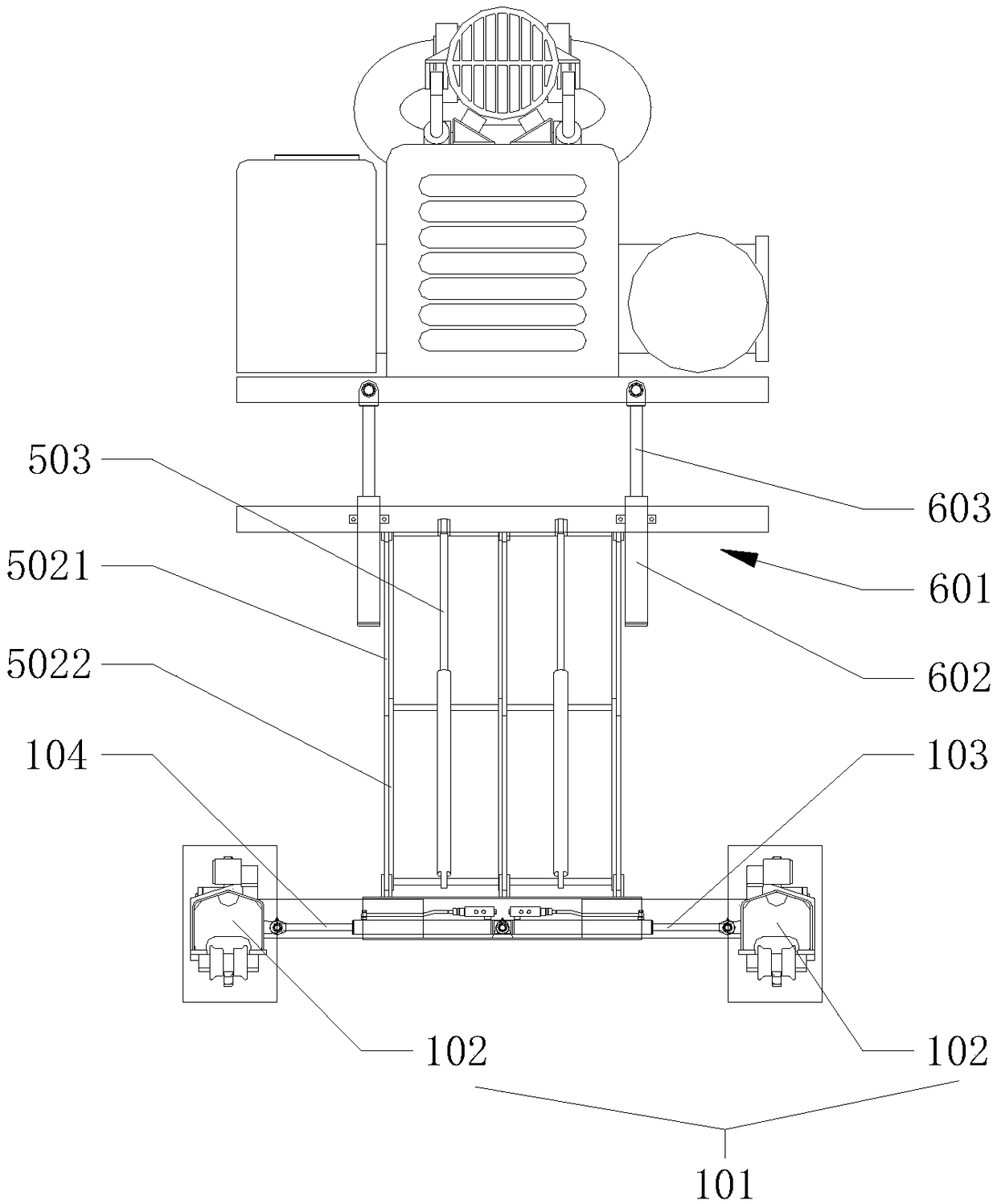

[0048] see figure 2 , the present embodiment discloses another two-stage lift type crawler pump vehicle. The crawler chassis 101 includes a crawler traveling mechanism 102, a second telescopic device 103 and a third telescopic device 104. The crawler traveling mechanism 102 is arranged on the bottom of the crawler chassis 101. On both sides, one end of the second telescopic device 103 is connected to one side of the crawler chassis 101 , and the other end is connected to the crawler traveling mechanism 102 on one side of the crawler chassis 101 . One end of the third telescopic device 104 is connected to the other side of the crawler chassis 101 , and the other end is connected to the crawler traveling mechanism 102 on the other side of the crawler chassis 101 . The bottom of the cylinder 602 of the first lifting rod 601 extends to between the crawler running mechanisms 102 on both sides of the crawler chassis 101 . By installing a lateral telescopic device between the crawl...

Embodiment 3

[0050] see Figure 4 , the present embodiment discloses another double-stage lifting crawler pump vehicle. Including a power station 1101 and a double-stage lifting crawler pump vehicle, the power station 1101 includes a hydraulic station 801, an engine 901, an energy output mechanism, and a power station moving mechanism 1103 (in this embodiment, the hydraulic station moving mechanism 1102 can adopt the same embodiment The same crawler chassis as in No. 1, the crawler chassis includes a hydraulic crawler traveling mechanism, the hydraulic crawler traveling mechanism drives the transmission wheel through a hydraulic motor, and then drives the crawler to work; wheeled vehicles can also be used as the hydraulic station moving mechanism). The hydraulic station 801, the engine 901 and the energy output mechanism 1102 are arranged on the crawler chassis of the power station 1101 or the wheeled vehicle carrying platform, the power output shaft of the engine 901 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com