Industrially-applicable method for preparing polymer foamed material by using supercritical fluid technology

A supercritical fluid and foaming material technology, which is applied in the field of industrialized supercritical fluid technology to prepare polymer foaming materials, can solve the problems of uneven pore size distribution, low pressure reduction rate, small foaming ratio, etc. The effect of high expansion ratio, fast pressure reduction rate and short equilibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

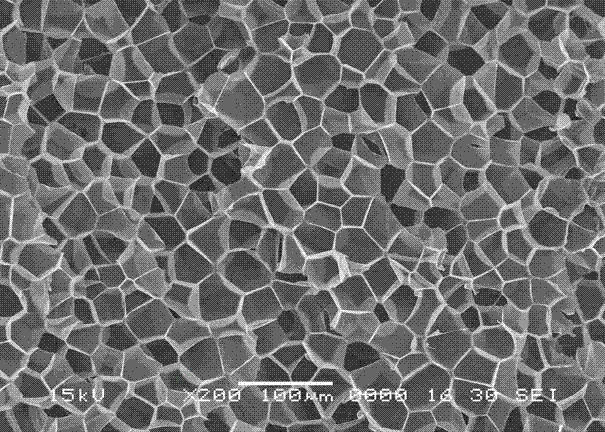

Embodiment 1

[0045]Firstly, general-purpose polypropylene pellets with low crystallinity are selected, and a conventional mixing process is used to produce a embryonic plate with a certain size (180×180×10mm) and a crystallinity of less than 30%.

[0046] Then place the prefabricated polypropylene foamed embryonic board (180×180×10mm) in a high-temperature foaming container, where the foaming container should reserve enough space for volume expansion required for swelling, penetration and nucleation to ensure that the board can be uniform. of nucleation.

[0047] Then replace the oxygen in the foaming container, and then fill it with high-pressure gas CO 2 . The temperature of the high-pressure vessel is kept constant at 145°C, the pressure of the supercritical fluid is controlled at 20MPa, and the swelling and permeation is 0.5h.

[0048] After the balance is reached, the pressure is quickly released to 0, and the pressure release rate is controlled at 50MPa / s. The swollen polypropylene...

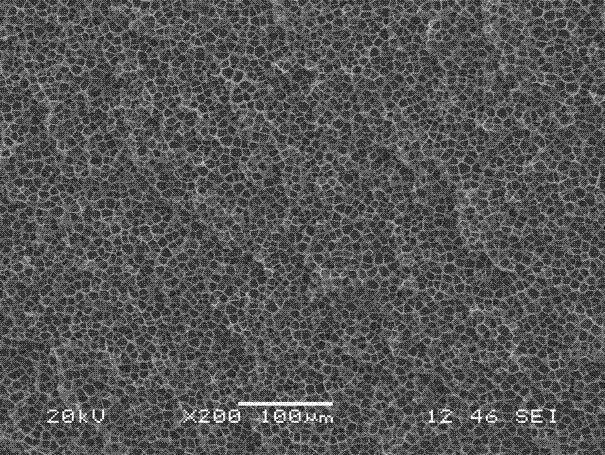

Embodiment 2

[0050] Firstly, general-purpose polypropylene pellets with low crystallinity are selected, and a conventional mixing process is used to produce a embryonic plate with a certain size (180×180×10mm) and a crystallinity of less than 30%.

[0051] Then place the prefabricated polypropylene foamed embryonic board (180×180×10mm) in a high-temperature foaming container, where the foaming container should reserve enough space for volume expansion required for swelling, penetration and nucleation to ensure that the board can be uniform. of nucleation.

[0052] Then replace the oxygen in the foaming container, and then fill it with high-pressure gas CO 2 . The temperature of the high-pressure vessel is kept constant at 150°C, the pressure of the supercritical fluid is controlled at 15MPa, and the swelling and permeation is performed for 1 hour.

[0053] After the balance is reached, the pressure is quickly released to 0, and the pressure release rate is controlled at 100MPa / s. The swo...

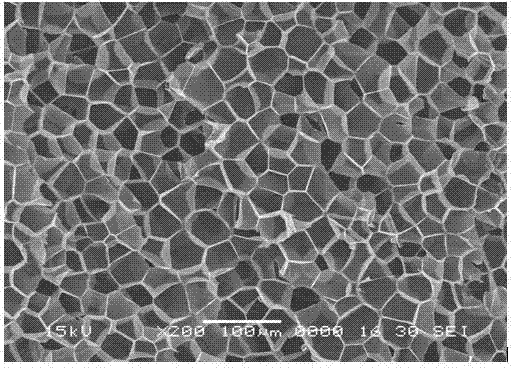

Embodiment 3

[0055] Firstly, general-purpose polypropylene pellets with low crystallinity are selected, and a conventional mixing process is used to produce a embryonic plate with a certain size (180×180×10mm) and a crystallinity of less than 30%.

[0056] Then place the prefabricated polypropylene foamed embryonic board (180×180×10mm) in a high-temperature foaming container, where the foaming container should reserve enough space for volume expansion required for swelling, penetration and nucleation to ensure that the board can be uniform. of nucleation.

[0057] Then replace the oxygen in the foaming container, and then fill it with high-pressure gas CO 2 . The temperature of the high-pressure vessel was kept constant at 155°C, the pressure of the supercritical fluid was controlled at 10MPa, and the swelling and permeation took 1.5h.

[0058] After the balance is reached, the pressure is quickly released to 0, and the pressure release rate is controlled at 300MPa / s. The swollen polypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com