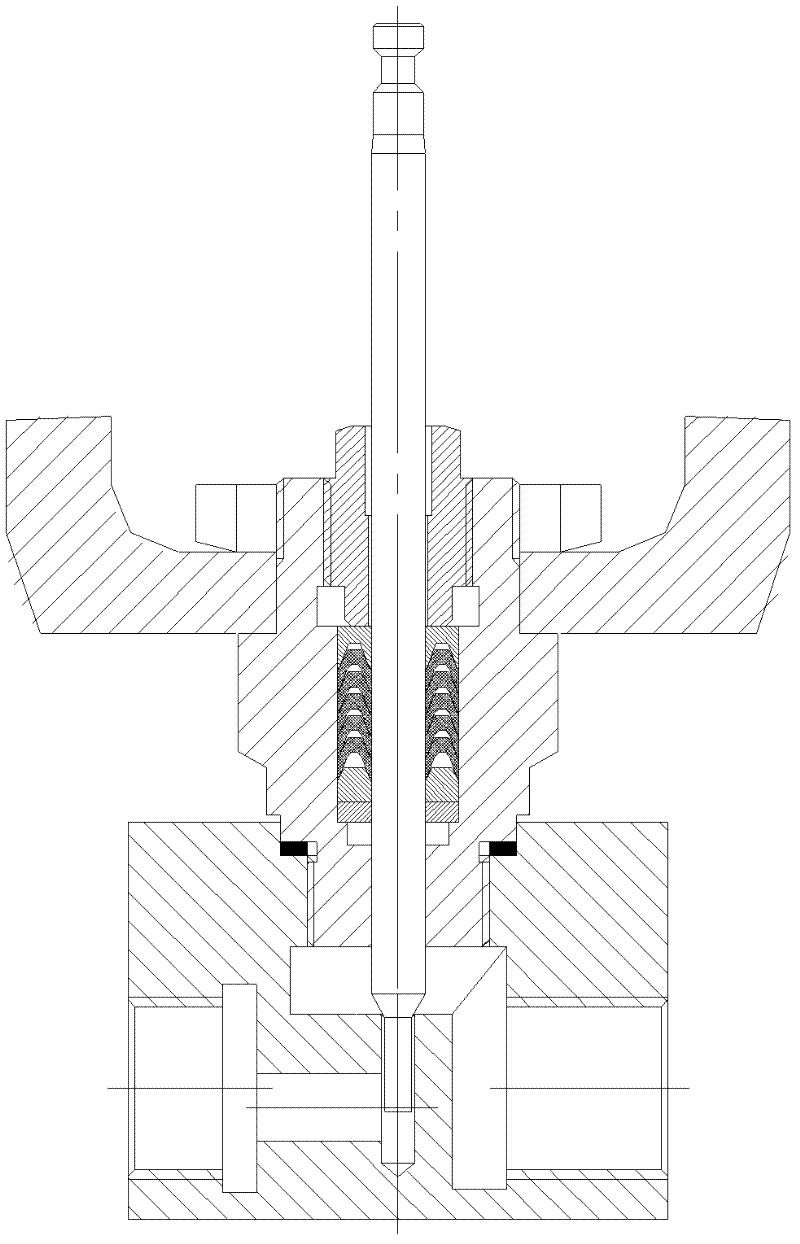

Micro-flow regulating valve

A flow control valve and tiny technology, applied in the field of flow valves, can solve the problems of poor adjustment accuracy, low leakage level, impurity blockage, etc., and achieve the effects of accurate and easy flow control, guaranteed processing strength, and improved leakage level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

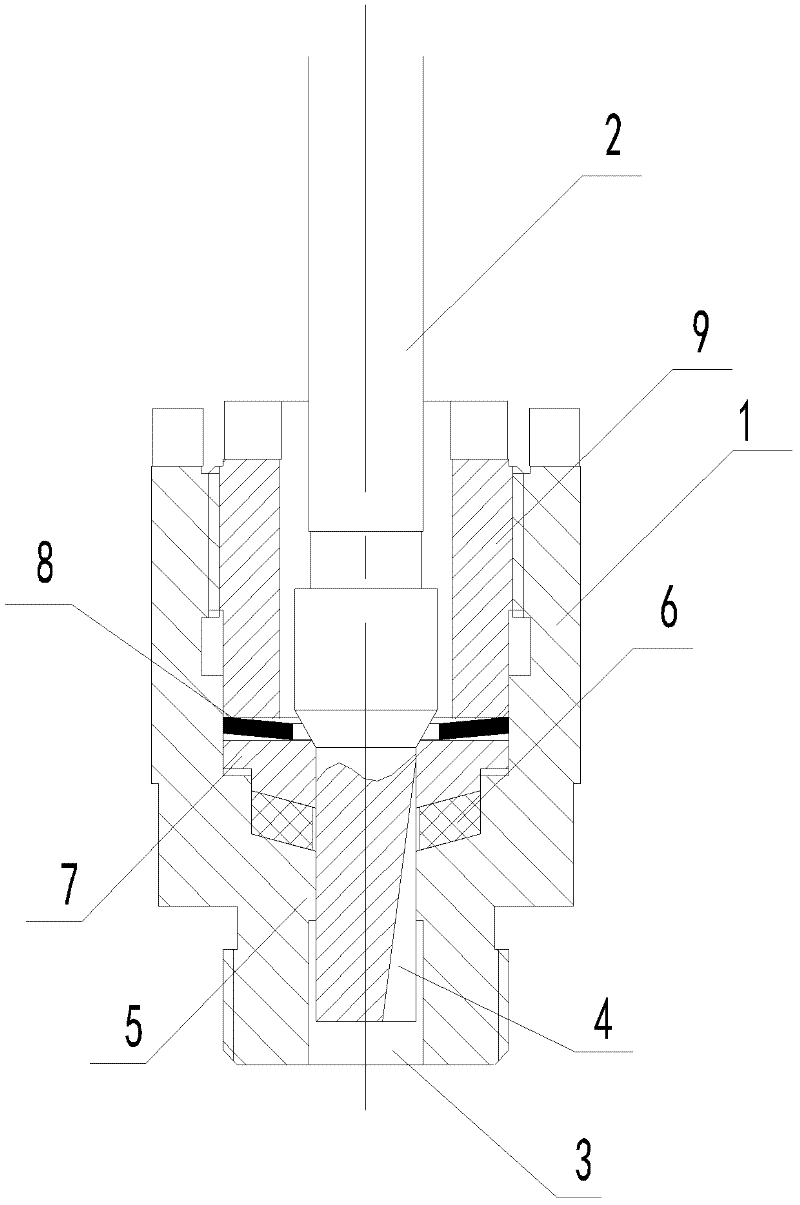

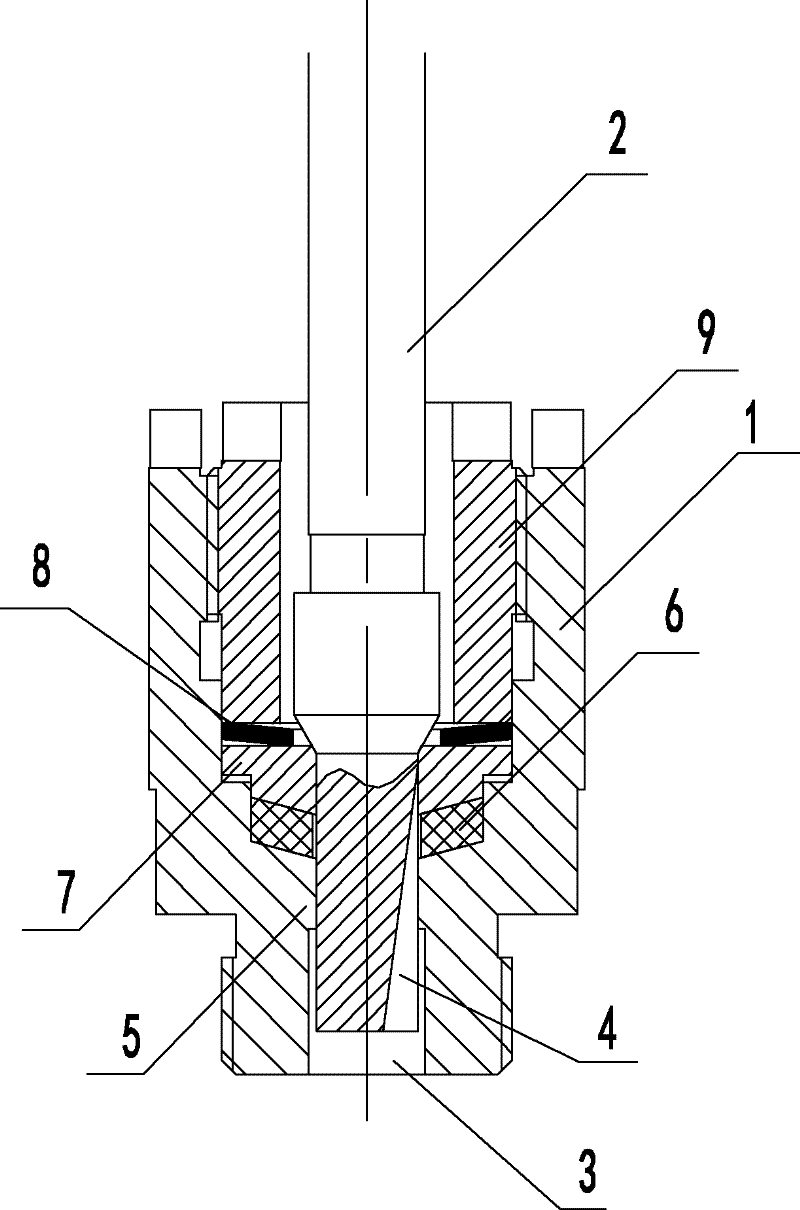

[0016] see figure 2 , a small flow regulating valve, including a sleeve valve seat 1 and a valve core 2 arranged in the sleeve valve seat, a boss 2 is arranged in the water outlet 3 of the sleeve valve seat 1, and the head of the valve core 2 Closely matched with the boss 5, the head side of the valve core 2 is provided with a fluid passage groove 4 that gradually becomes smaller along the water inlet direction. In order to facilitate processing and precise control of the flow rate, the fluid passage groove 4 is triangular. The tank body, the end of the tank body close to the top of the head of the valve core 2 is the bottom edge of the triangle, with the largest flow area, and along the water inlet direction, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com