Valve mounting mechanism, method for controlling position and angle of valve and fire truck

A technology for installing mechanisms and valves, which is applied in the direction of mechanical equipment, pipes/pipe joints/fittings, pipe components, etc. It can solve the problem of difficulty in ensuring the accuracy of valve installation position and angle, difficulty in installation and disassembly, and inability to control the installation position and angle of valves and other problems to achieve the effect of eliminating pipeline manufacturing errors, simple and fast installation and disassembly, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

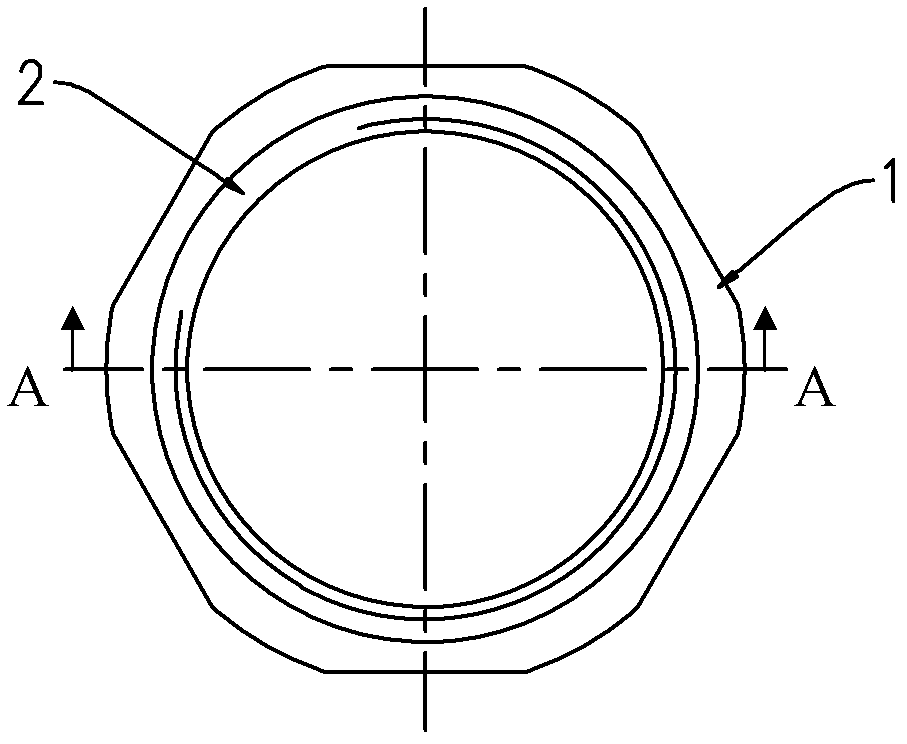

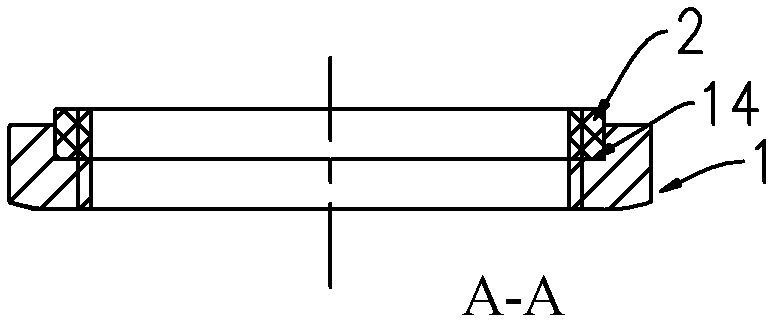

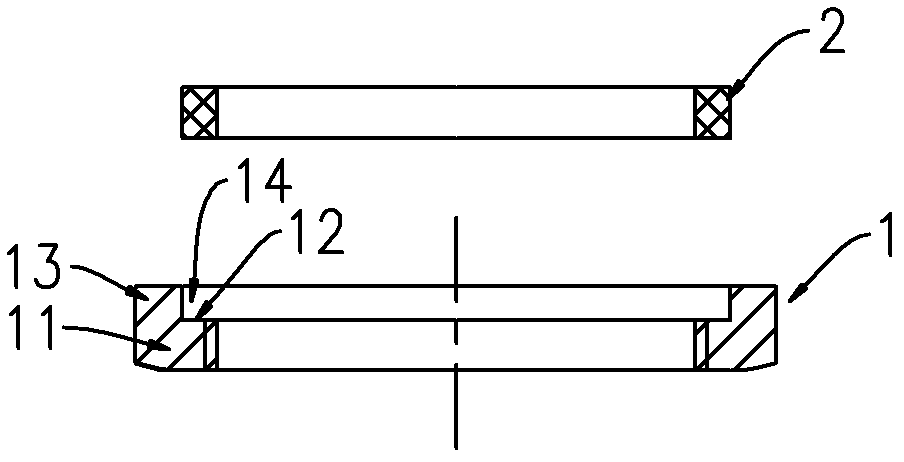

[0015] Figure 1 to Figure 3 A mounting mechanism for a threaded connection type valve in some embodiments of the invention is shown. Such as Figure 1 to Figure 3 As shown, the installation mechanism of the threaded valve includes a locking part 1 and an annular sealing part 2. The locking part 1 includes a nut 11, and the outer half of an end face 12 of the nut 11 extends along the axial direction of the nut 11 to form a The ring body 13 forms an annular stepped portion 14 with the end surface 12 of the nut 11 , and the annular sealing component 2 is disposed on the stepped portion 14 .

[0016] The locking part 1 can be made of metal material in some embodiments. In some embodiments, the sealing member 2 can be made of soft non-metallic materials, such as rubber, silicone and the like.

[0017] The inner diameter of the ring body 13 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com