Installation method of vacuum pump for central negative pressure suction station

An installation method and vacuum pump technology, applied in the direction of pump devices, suction devices, pumps, etc., can solve the problems of large width of channel steel foundation, waste of space, deformation of channel steel foundation, etc., so as to improve bearing capacity, installation accuracy and bearing capacity effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] like Figure 12 As shown, the water ring pump A is installed on the channel steel foundation B in the prior art.

[0046] like Figure 1 to Figure 11 As shown, it is the vacuum pump installation method for the central negative pressure suction station of the present invention, comprising the following steps:

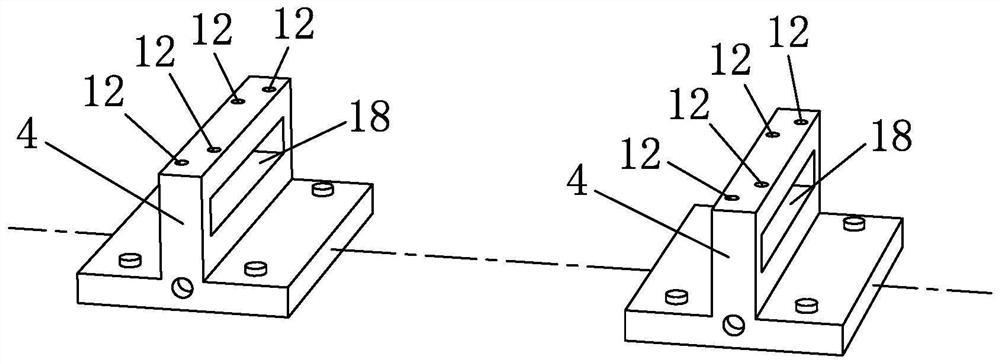

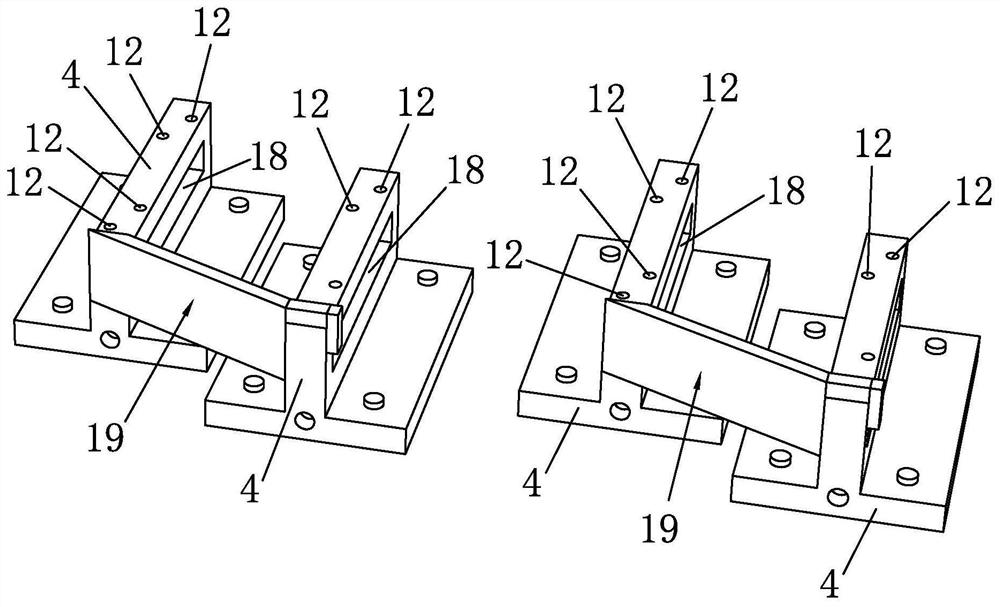

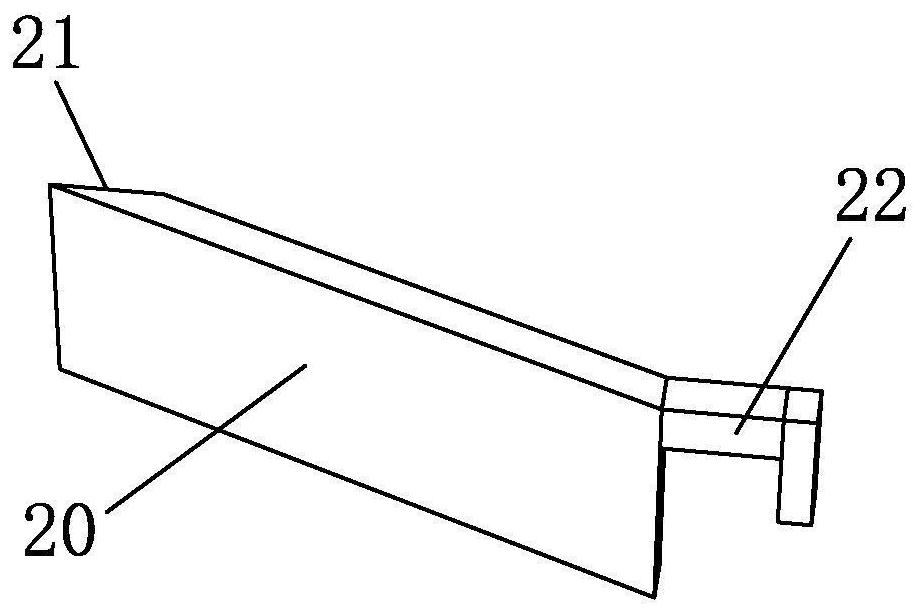

[0047] a. Measure the line on the ground to determine the installation positions of the two vacuum pumps 1 . Each vacuum pump 1 is provided with two pre-embedded bases 4 , and each pre-embedded base 4 is provided with four first embedded steel plates 5 for fixing. Threaded holes 12, the four first threaded holes 12 are distributed at parallelogram points. During the installation of each vacuum pump 1, one of the pre-embedded bases 4 is used as a standard pre-embedded base 4, and the other pre-embedded base 4 is used as inclined The distance between the standard embedded base 4 and the oblique embedded base 4 is based on the length of the embedded steel plate 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com