Permanent magnet high-voltage vacuum circuit breaker

A vacuum circuit breaker and permanent magnet technology, applied in high voltage air circuit breakers, high voltage/high current switches, circuits, etc., can solve the problems of long operation time, unreliable latching, complicated operation, etc., and achieve convenient installation and maintenance, The effect of increasing the scope of application and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

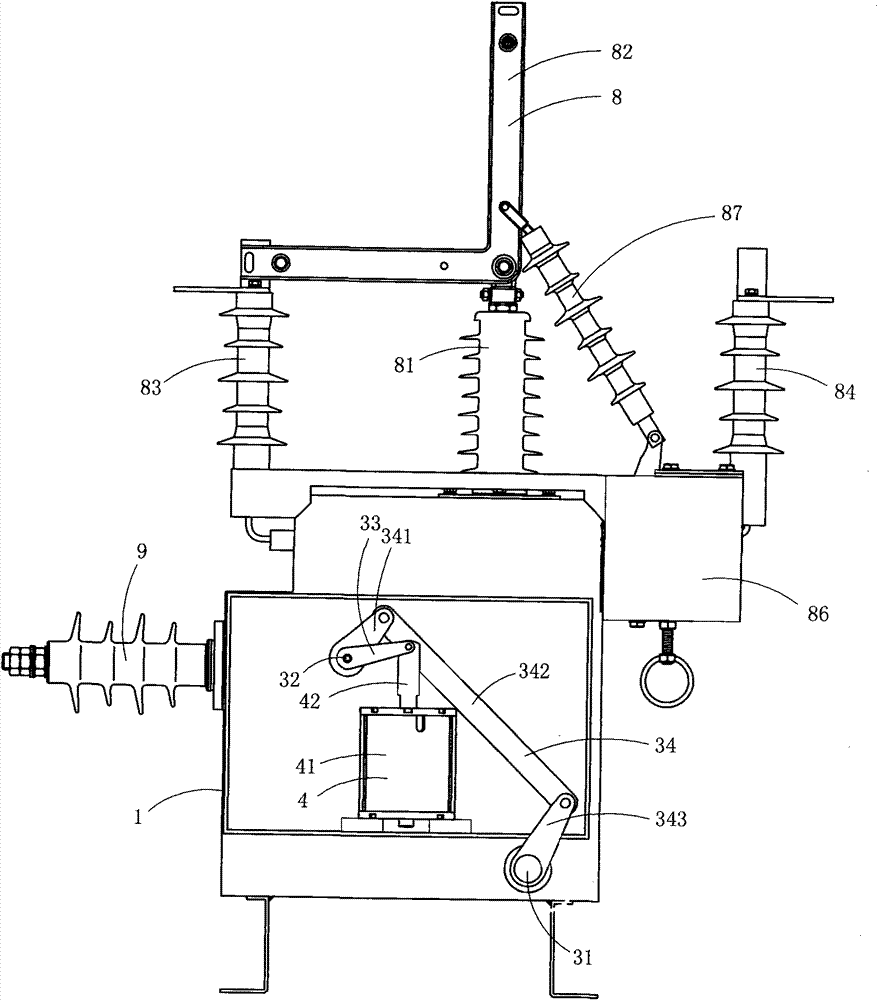

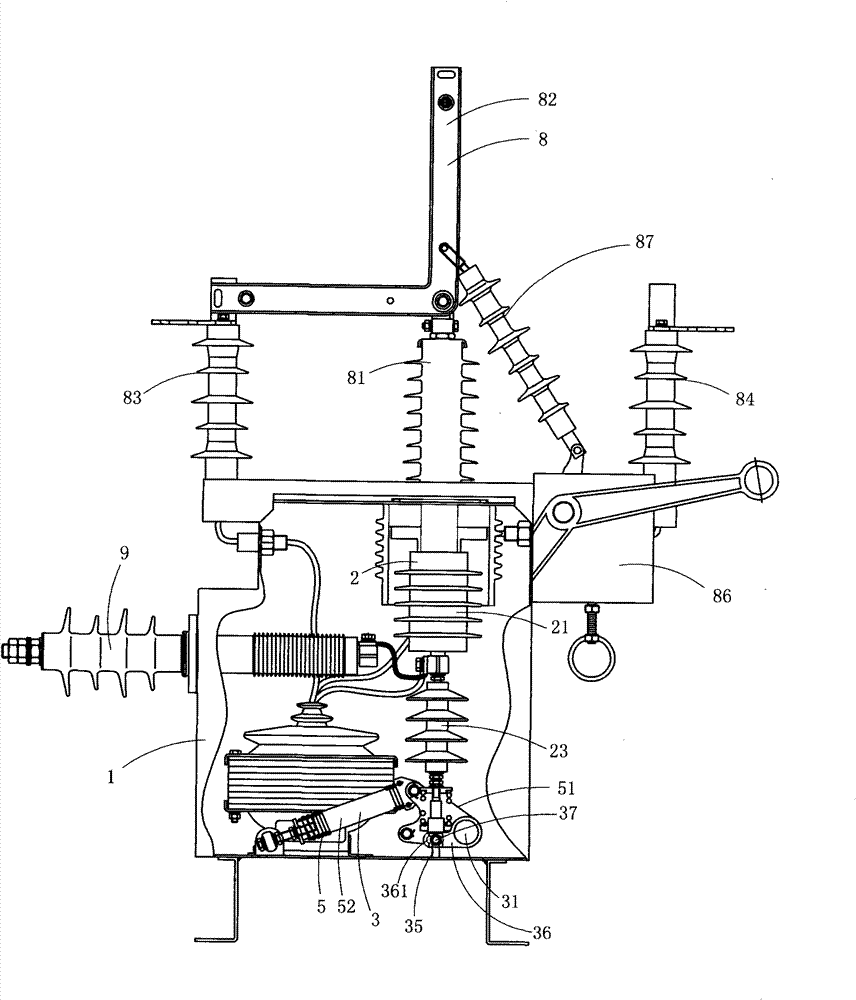

[0029] figure 1 and figure 2 A specific embodiment of the invention is shown in which, figure 1 It is a structural schematic diagram of the first structure of the present invention; figure 2 for figure 1 A schematic diagram of the structure of the permanent magnet high-voltage vacuum circuit breaker when viewed from another angle after some components are removed.

[0030] This embodiment is a permanent magnet high voltage vacuum circuit breaker, see figure 1 and figure 2 , including housing 1, vacuum arc extinguishing mechanism 2, operating mechanism 3, permanent magnet drive device 4 and buffer mechanism 5.

[0031] See figure 1 and figure 2 , each of the vacuum interrupter mechanisms 2 includes a vacuum interrupter 21, and an insulating pull rod 23 for driving the moving contact in the vacuum interrupter 21 to move in a straight line; the insulating pull rods 23 are arranged vertically;

[0032]The permanent magnet driving device 4 includes a body 41 and a drive...

Embodiment 2

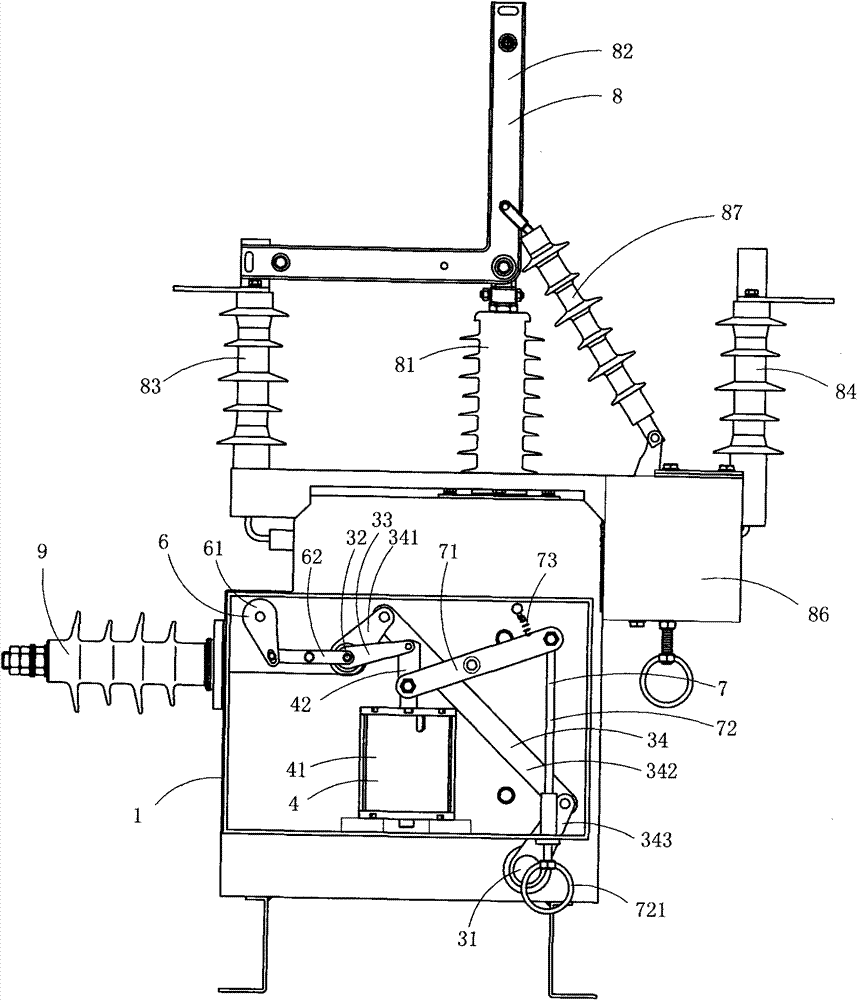

[0041] image 3 It is a structural schematic diagram of the second structure of the present invention, showing the second specific implementation mode of the present invention.

[0042] This embodiment is basically the same as Embodiment 1, the difference is: see image 3 , the vacuum circuit breaker also includes an opening and closing indicating mechanism 6 and a manual opening mechanism 7 .

[0043] The opening and closing indicating mechanism 6 includes an opening and closing indicator 61 and a linkage rod 62 which are rotatably arranged on the housing 1; one end of the linkage lever 62 is connected with the opening and closing indicator 61, and the other end is fixed on the driving auxiliary on axis 32. The indicating mechanism is relatively simplified, and the installation and maintenance are relatively convenient.

[0044] The manual opening mechanism 7 includes an opening operating lever 71, a manual pull rod 72, and a return spring 73 for resetting the opening oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com