Fixing device for acoustic emission sensor in rock triaxial experiment under confining pressure

An acoustic emission sensor and fixing device technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of detachment of acoustic emission sensors, signal interference, and too much signal interference information, so as to facilitate accurate positioning of rock sample fractures. Prevent damage and destruction, reduce the effect of interfering signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

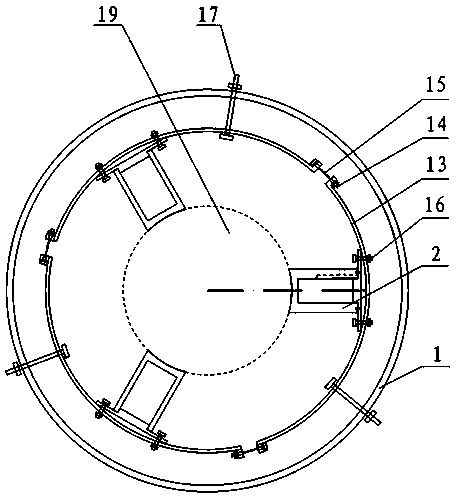

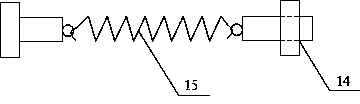

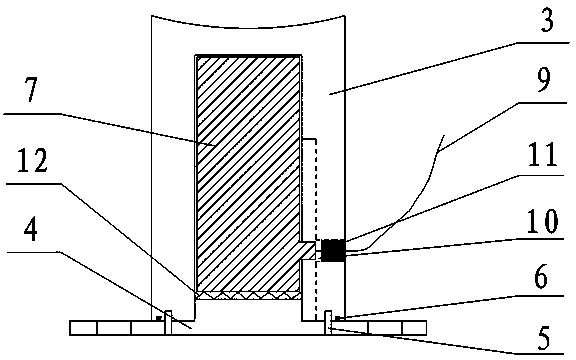

[0017] figure 1 As shown, the acoustic emission sensor fixing device for rock triaxial experiment under confining pressure of the present invention is mainly composed of a fixed ring 1, a plurality of acoustic emission sensor sealing chambers 2 and a pre-tensioning mechanism. The pre-tensioning mechanism includes a plurality of arc-shaped pre-tensioning steel sheets 13 and an adjusting bolt 14 connecting the plurality of arc-shaped pre-tensioning steel sheets 13 into a circular ring. In connection, the length of the spring 15 can be adjusted by the adjusting bolt 14 connected to the spring 15. The acoustic emission sensor sealing chamber 2 is fixed to the arc-shaped pre-tightening steel sheet 13 through the screw holes on the sealing cover. The adjusting bolt 14 is used to adjust the length of the spring 15 so that the acoustic emission sensor sealing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com