Direct-water-supply type humidifying system

A technology of humidification system and water inlet pipe, which is applied in the direction of air humidification system, heating and ventilation control system, heating and ventilation safety system, etc. It can solve the problems of large amount of atomization, inconvenient movement, inconvenient centralized management of line control humidifiers, etc. , to achieve the effect of uniform humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

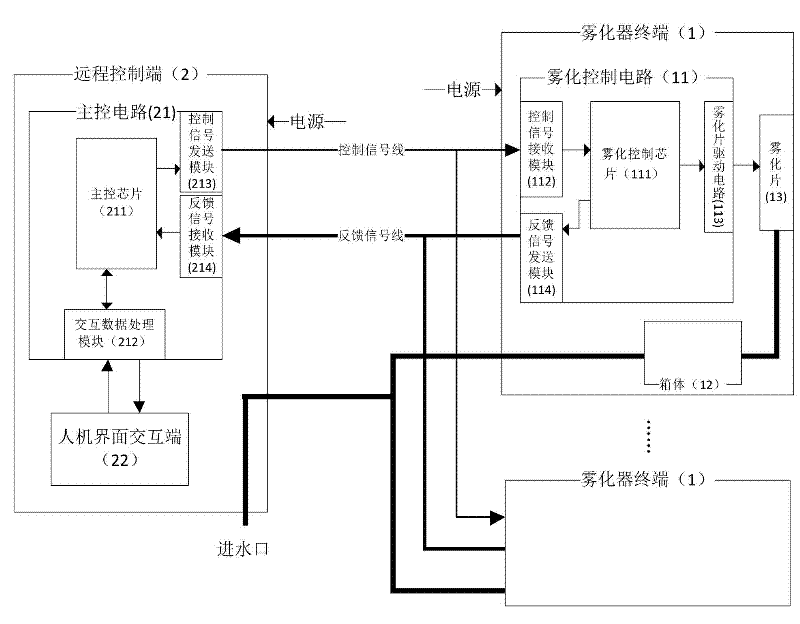

[0029] Reference figure 1 , The system structure diagram of the first embodiment of the present invention includes at least one atomizer terminal 1, and also includes a remote control terminal 2 connected to the atomizer terminal 1 through a control signal line. Each atomizer The device terminal 1 is also connected with a water distribution pipe, and the atomizer terminal 1 realizes different working modes and produces different atomization amounts according to the control signal transmitted from the remote control terminal 2. The atomizer terminals 1 are evenly distributed in the workshop, and the water pipes, power lines, signal lines, etc. are arranged in a centralized and unified manner to make it an effective overall control system. The different working modes are spray atomization at designated time, continuous spray atomization at intervals, preset spray atomization and so on.

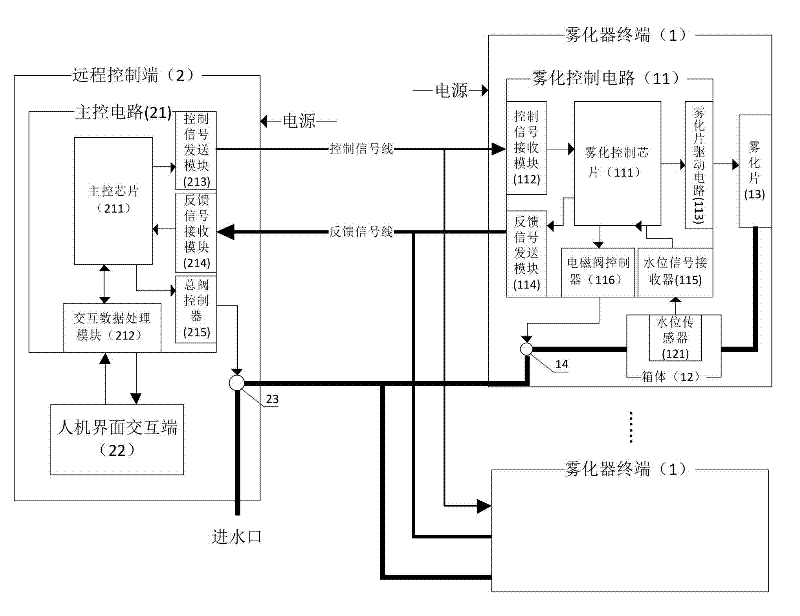

[0030] Further as a preferred embodiment, the atomizer terminal 1 is also connected to the remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com