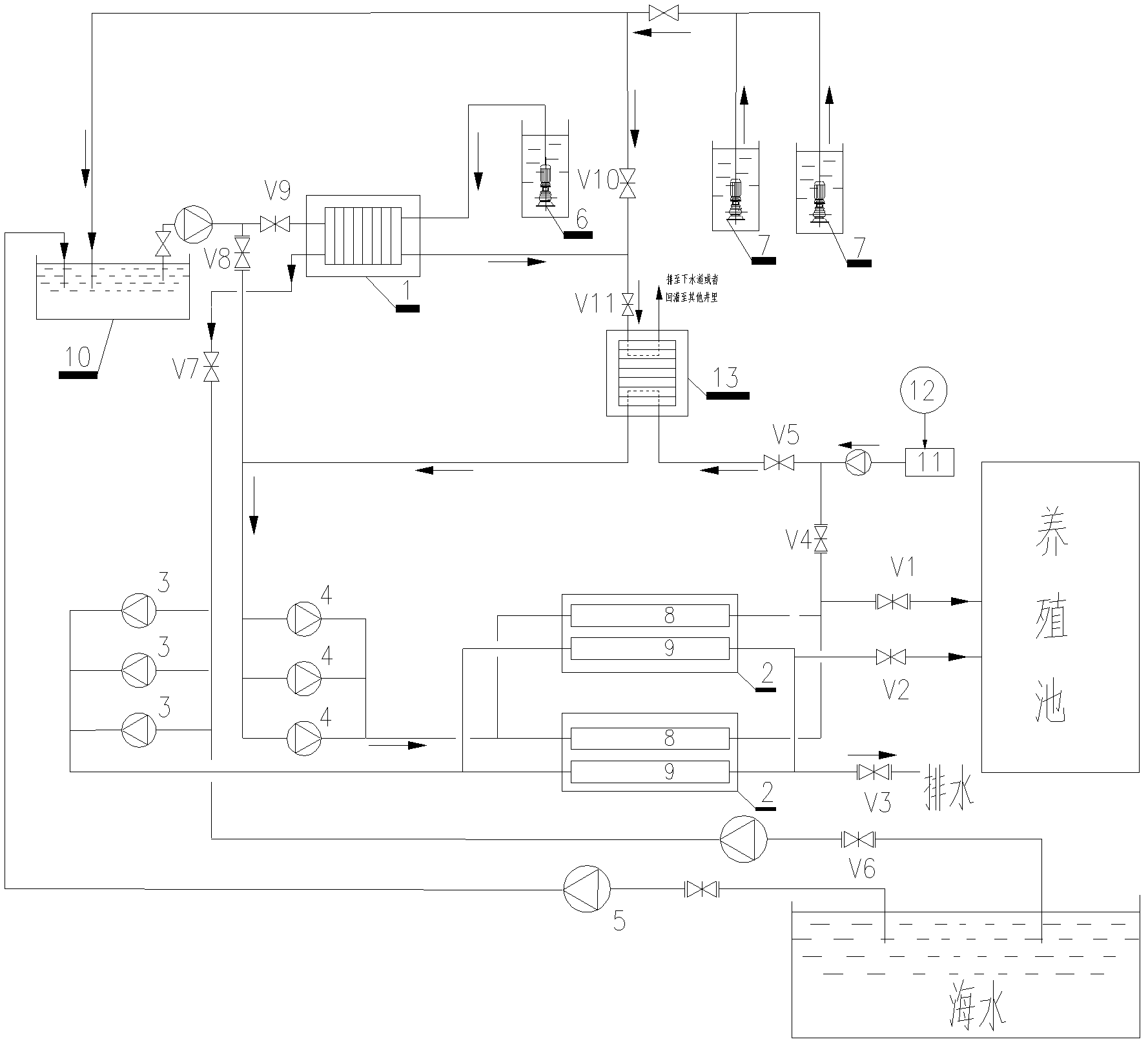

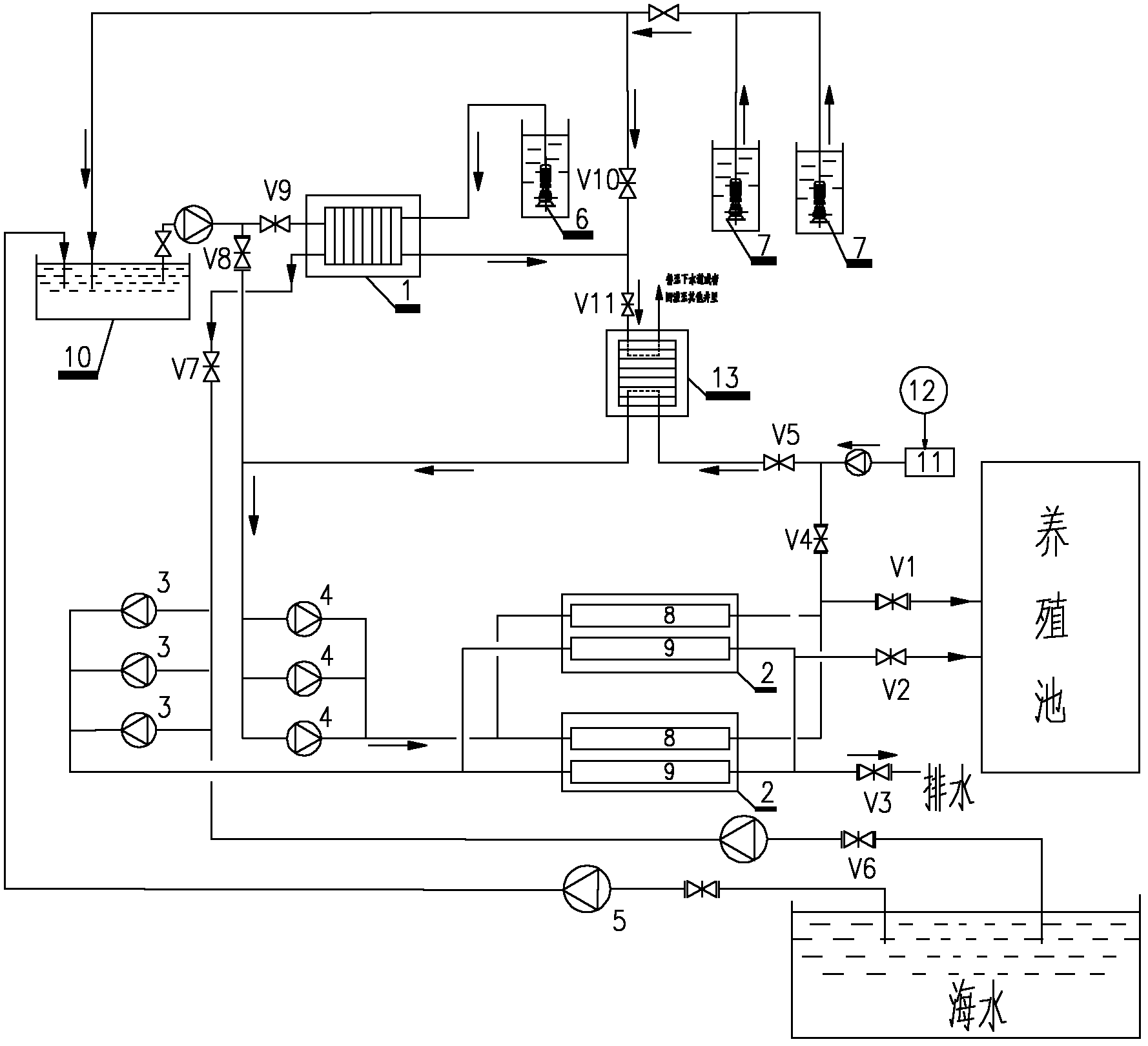

Summer and winter cold and hot water supply method for cultivation farm

A technology of hot water supply and supply method, which is applied in the direction of heat pumps, refrigerators, refrigeration components, etc., can solve the problems of resource waste, pollutants are easy to pollute the environment, etc., and achieve the effects of environmental protection, convenient operation and operation management, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) A high-temperature hot water well is set up in the breeding farm with a water output of 50m 3 / h, the water outlet temperature is about 70℃; there are 2 fresh water wells, and the water output of a single well is 60m 3 / h, the outlet water temperature is about 19℃; there is sufficient 28℃ seawater available in summer.

[0017] (2) According to the requirements of the breeding technology, it can be supplemented with 30℃ hot water about 150m per hour in winter 3 / h, where 19℃ fresh water 75m 3 / h, 75m of sea water at -5℃ 3 / h; In summer, it can add about 150m of 16℃ cold water every hour 3 / h, where 19℃ fresh water 75m 3 / h, 75m in sea water at 28℃ 3 / h.

[0018] According to the overall load requirements of the project, two fully enclosed twin-screw water source heat pump units are selected, and the two units are set in parallel, which can be steplessly adjusted according to load changes. In order to ensure the amount of hot water source required by the host and reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com