Energy-saving anti-freezing system for coal mine well port

An antifreeze system and energy-saving technology, applied in wellbore/well components, isolation devices, earthwork drilling and mining, etc., can solve the problems of poor effect, high energy consumption for heating and antifreeze, reduce environmental pollution, improve equipment utilization, and protect the environment significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

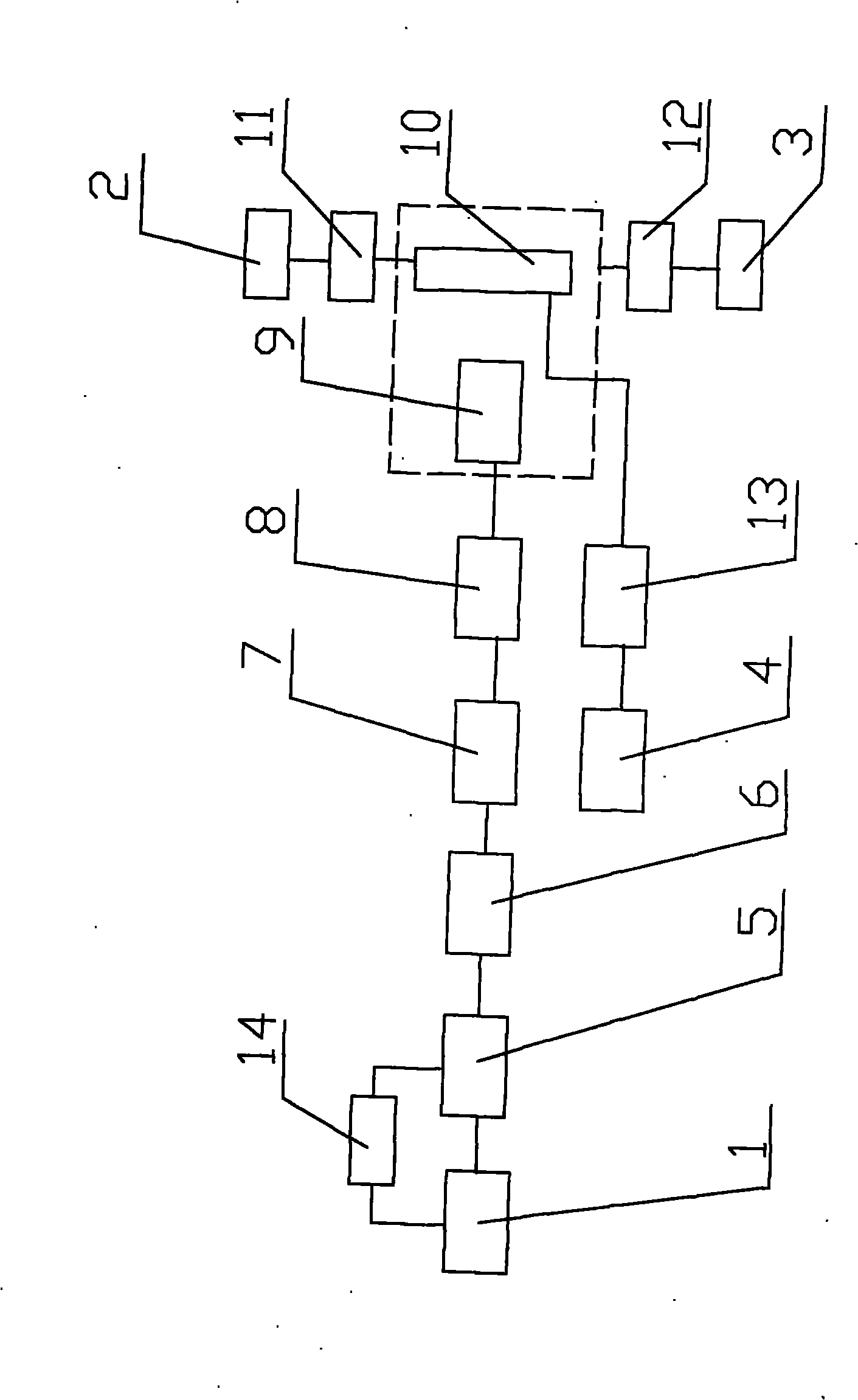

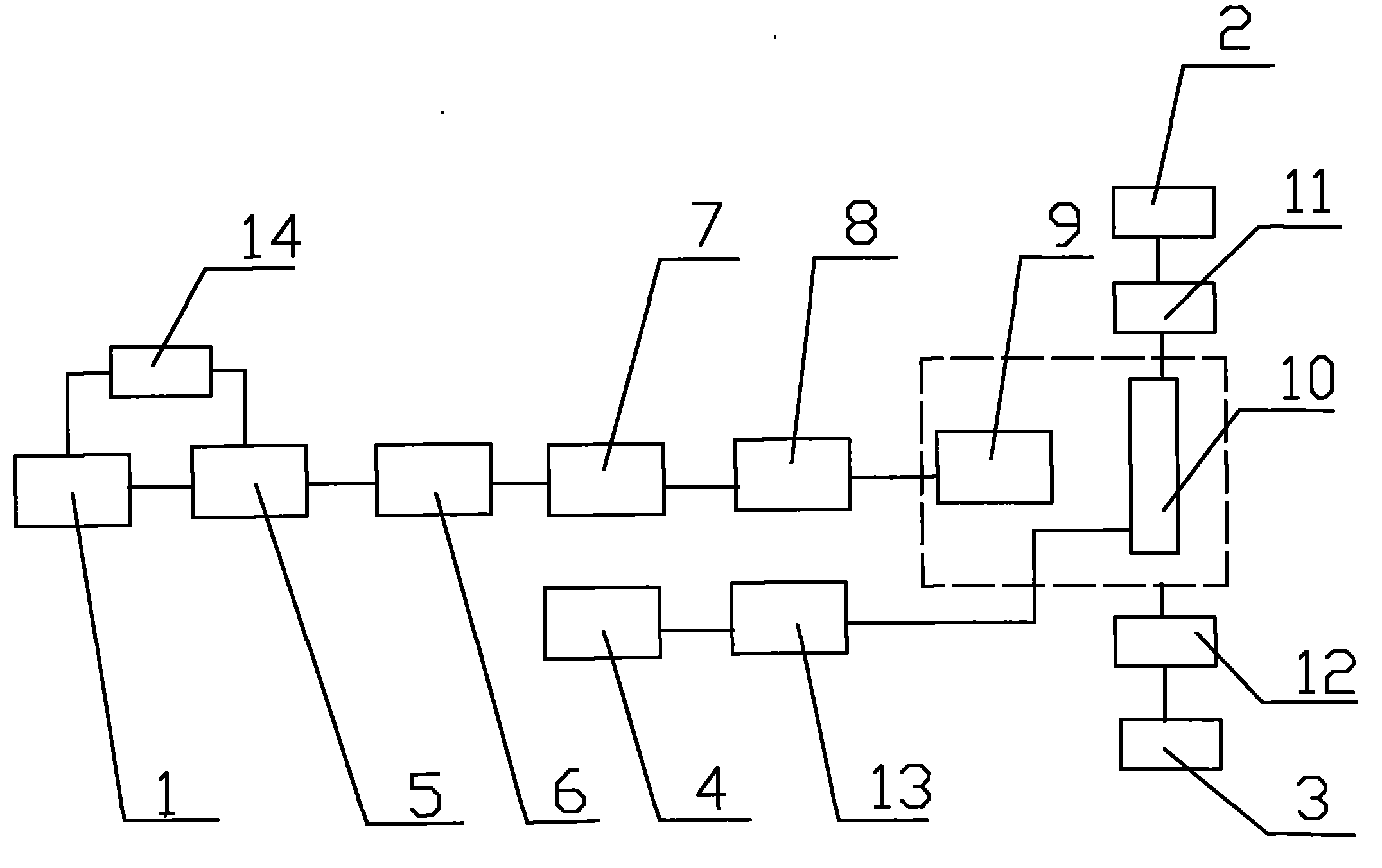

[0025] Such as figure 1 As shown, sedimentation tank 1, sewage source plate heat exchanger 5, intermediate water system 6, water source heat pump unit 7, fresh air unit 8, and wellhead air heat exchanger 9 are connected in sequence, and sedimentation tank 1 is connected to sewage source plate heat exchanger 5 A purification and filtration system 14 is provided between them. The intermediary water system 6 includes a softening and descaling and water supply system. An induced draft fan 12 is installed on the waste heat pipe of the air compressor 3. The waste heat generated by the air compressor 3 is sent to the wellhead for heating through the induced draft fan 12. Cold air, coal gangue brick factory roasting kiln cooling section 2 is connected with fin heat exchanger 10 through pin heat exchanger 11 , and mine water clean water pool 4 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com