Heat pump system utilizing latent heat of solidification

A heat pump system and latent heat technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve problems such as large space, auger stuck, screw reliability problems, etc., to achieve simple process and reduce water consumption Quantity, the effect of saving the initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

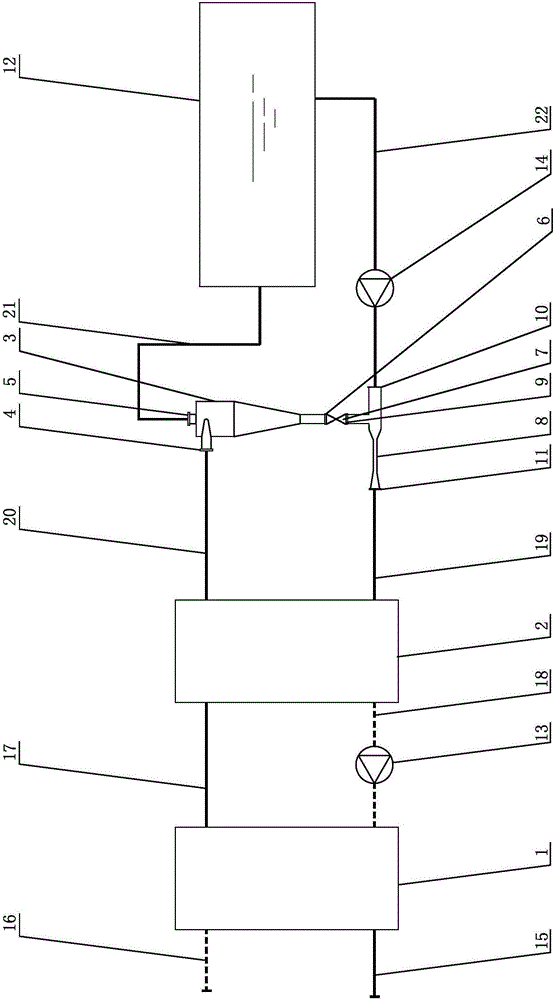

[0022] Specific implementation mode one, such as figure 1 As shown, a heat pump system using solidification latent heat in this embodiment is composed of a heat pump unit 1, heat exchange equipment 2, cyclone desander 3, sand control valve 7, ejector 8, water tank or pool 12, intermediary Water pump 13, water source water pump 14, end water supply pipe 15, end return water pipe 16, intermediary water supply pipe 17, intermediary water return pipe 18, water source water supply pipe 19, water source return pipe 20, water source drain pipe 21, water source inlet pipe 22, The cyclone desander 3 is respectively provided with a cyclone desander water inlet 4, a cyclone desander outlet 5, and a cyclone desander outlet 6; the ejector 8 is provided with There are ejector sand inlet 9, ejector water inlet 10, and ejector water outlet 11; the ejector water inlet 10 communicates with the water tank or pool 12 through the water source water inlet pipe 22; the water source water pump 14 is...

specific Embodiment approach 2

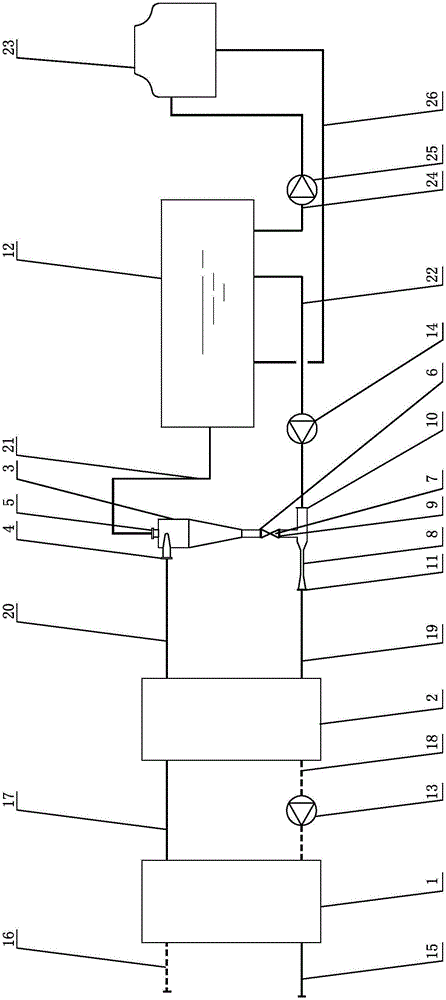

[0023] Specific implementation mode two, such as figure 2 As shown, the system of this embodiment differs from Embodiment 1 in that it also includes a cooling tower 23, a cooling tower water supply pipe 24, a cooling tower circulation pump 25, and a cooling tower return pipe 26. The cooling tower Water supply pipe 24 connects water tank or pool 12 and cooling tower 23; Described cooling tower return pipe 26 connects cooling tower 23 and water tank or pool 12; The beneficial effect of this embodiment is to use the cooling tower to melt ice, reduce the water consumption required by the system, and when the outdoor wet bulb temperature reaches a certain value, the cooling tower heating system cleans the water to a greater extent to increase the temperature, and the heat exchange equipment In this case, the system operates more efficiently.

specific Embodiment approach 3

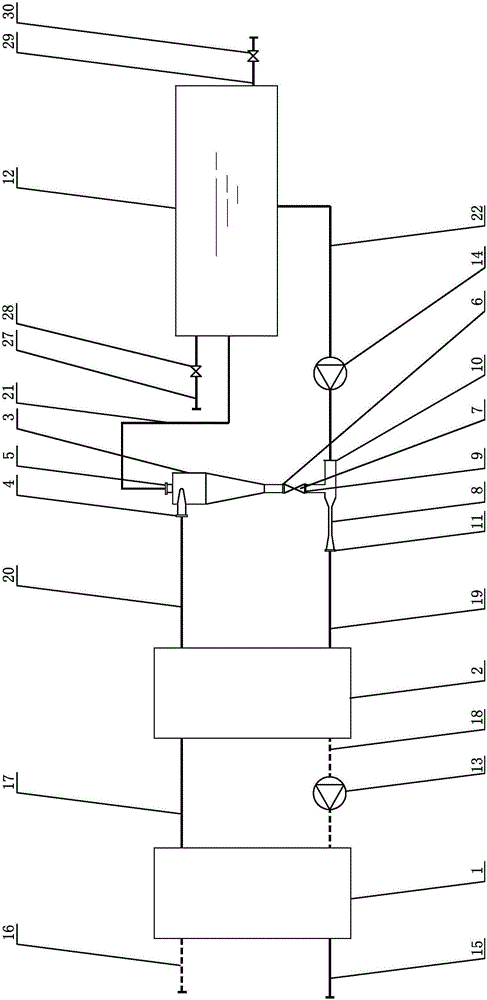

[0024] Specific implementation mode three, such as image 3 As shown, the system of this embodiment differs from Embodiment 1 in that it also includes an ice discharge pipe 27, an ice discharge valve 28, a water replenishment pipe 29, and a water replenishment valve 30. The ice discharge pipe 27 and water replenishment The pipes 29 communicate with the water tank or pool 12 respectively, the ice discharge valve 28 is arranged on the ice discharge pipe 27 , and the water supply valve 30 is arranged on the water supply pipe 29 . The beneficial effect of this embodiment is that when the amount of water is limited and not enough to support the normal operation of the entire system, the replenishment valve 30 is opened to replenish water to the water tank or pool 12, and the ice discharge valve 28 is opened to discharge ice from the water tank or pool 12.

[0025] working principle

[0026] The water source water pump 14 pumps the water in the water tank or pool 12 into the ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com