On-line sampling device for multi-phase flow liquid

A sampling device, multiphase fluid technology, applied in wellbore/well components, earthwork drilling and other directions, can solve problems such as poor applicability, poor representation, complex structure, etc., and achieve large sampling volume, low cost and high sampling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

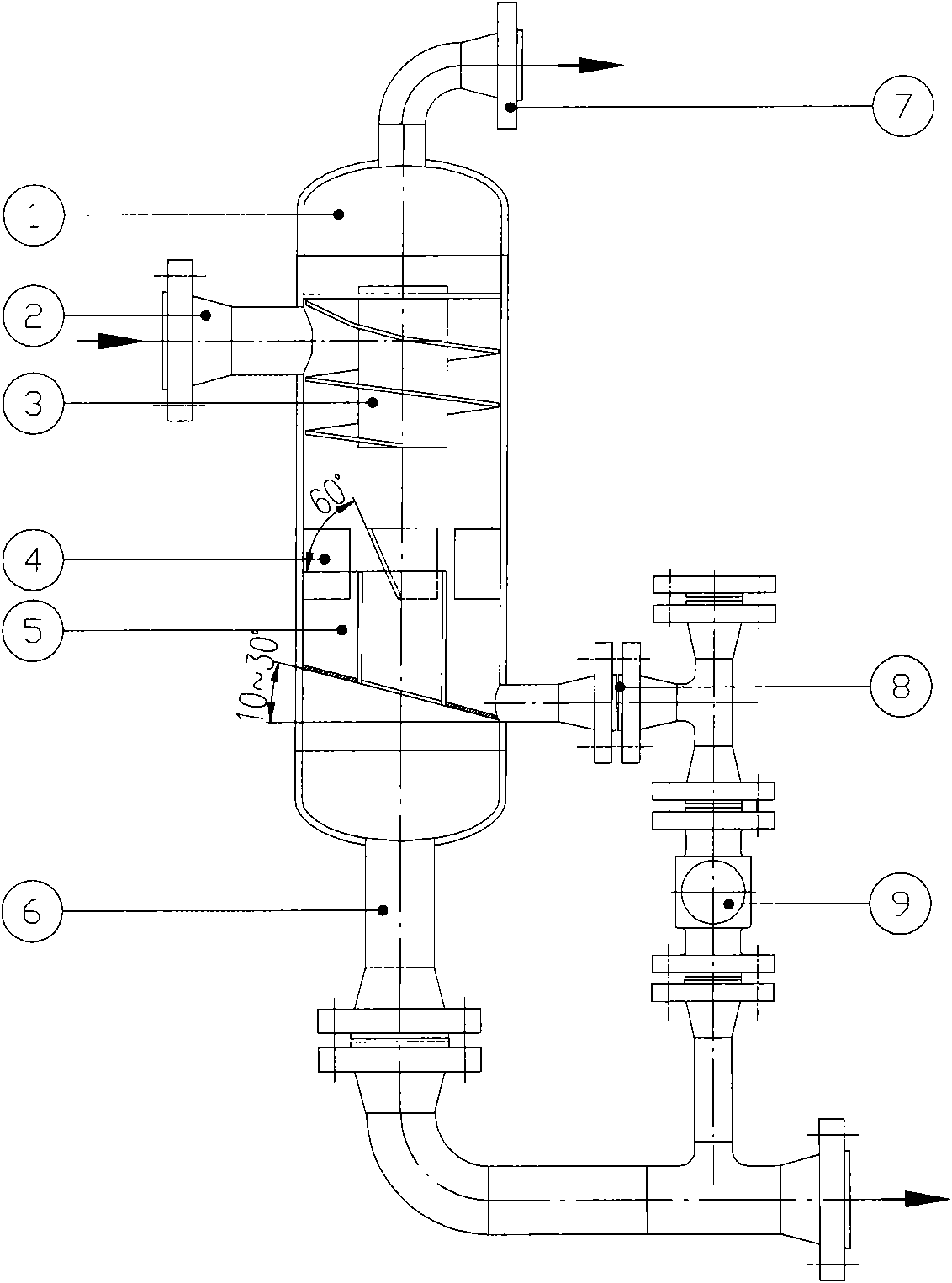

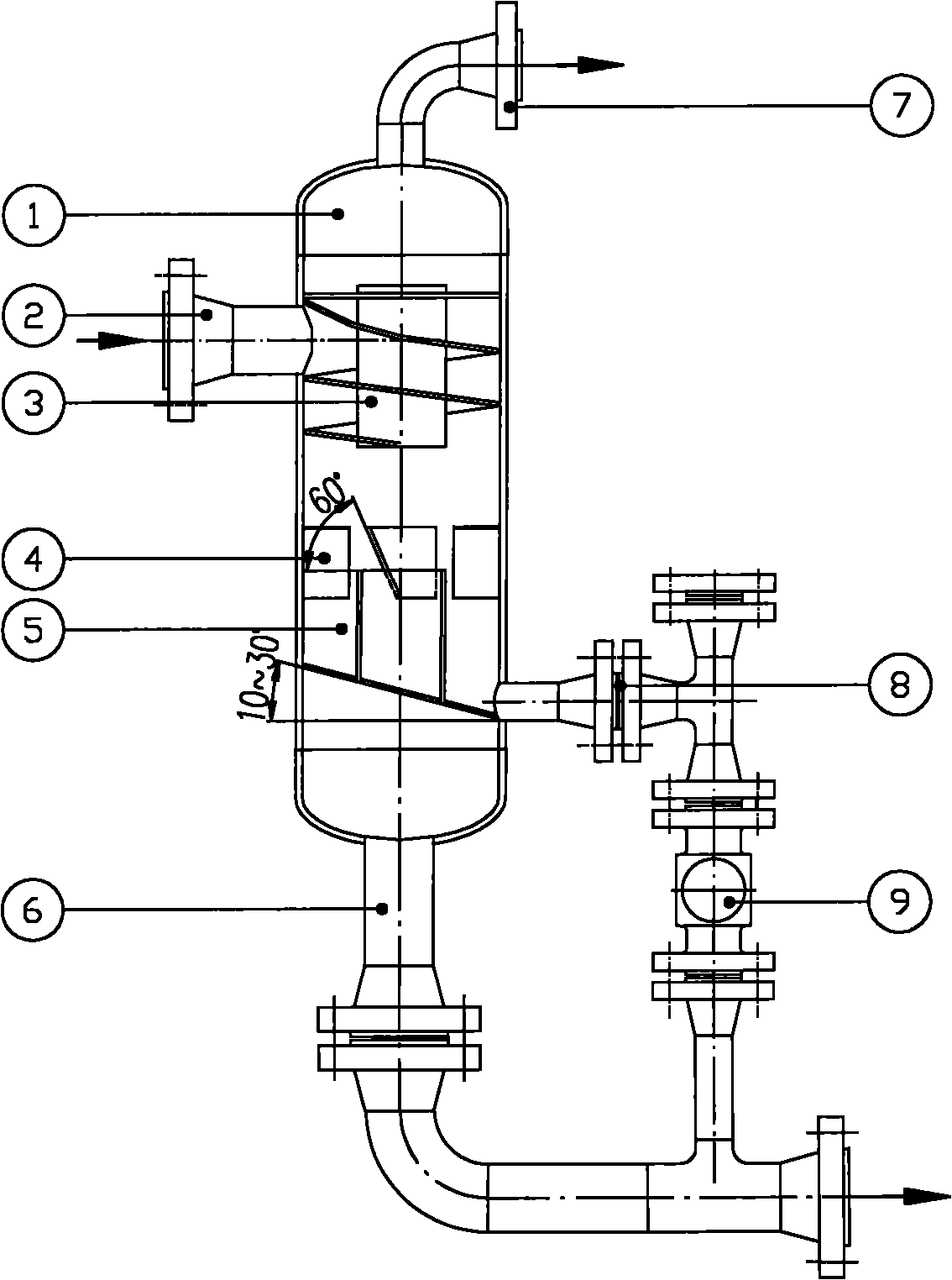

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] The present invention comprises a vertically installed container 1, a screw channel 3 with a spiral angle downwards is arranged in the container 1, and a multiphase fluid inlet pipeline 2 is connected to a hole on the side of the upper end of the container 1, and the multiphase fluid inlet pipeline 2 is connected to the screw channel. The inlets of 3 are connected, and the gas-liquid swirl can be forced to achieve centrifugal separation. The inner wall of the lower part of the container 1 is welded with an annular liquid storage bin 5, and the annular liquid storage bin 5 and the container 1 are provided with an inclination angle of 10-30 degrees in the radial direction. "L" shaped drainage baffles 4 are evenly distributed on the inner wall of the container between the liquid storage bin 5 and the screw channel 3, and the upper end of the "L" shaped drainage pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com