Structural deformation observation and data processing method at operation and maintenance stage of high-speed train

A technology for operation and maintenance and high-speed railways, applied in surveying and navigation, height/horizontal measurement, measuring devices, etc., can solve problems such as difficult to restore the state, no longer applicable to the operation period, and height failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

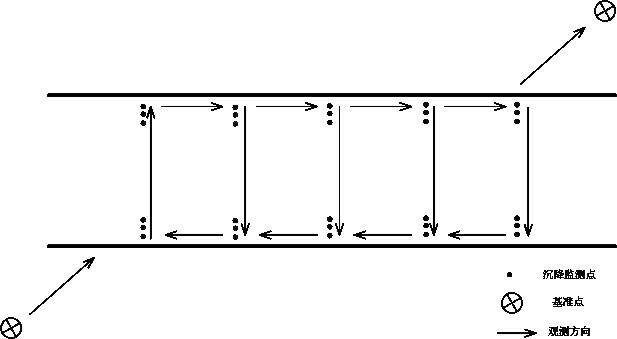

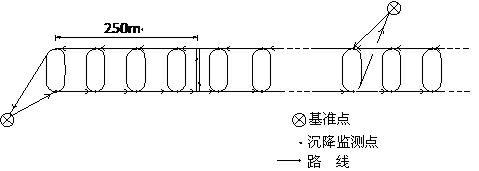

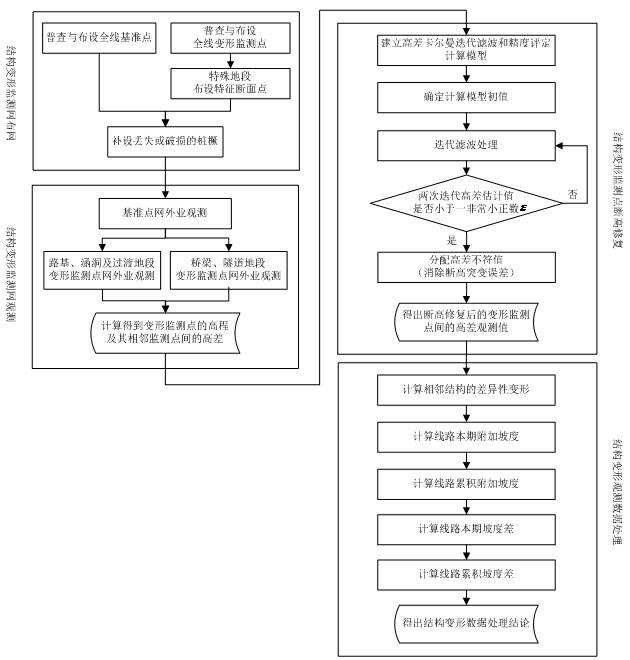

[0028] Considering that the working base point was severely damaged during the construction of the high-speed railway, it is difficult to restore the original state after re-embedding, and there are certain difficulties in the preservation and maintenance of the working base point during the operation period. After rigorous theoretical derivation and simulation calculation analysis, A new method of two-level network deployment and deformation observation for the deformation monitoring network during the operation period is proposed according to the reference point and the deformation monitoring point.

[0029] Network deployment method: the reference point network is laid out along the line, and a reference point is arranged every 1km or so, and the line leveling base points laid out during the construction period are used as much as possible, and the laying specification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com