Method for determining vibration working stress limit of aircraft anti-skidding braking control box

A work stress, anti-skid braking technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as unrealistic data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

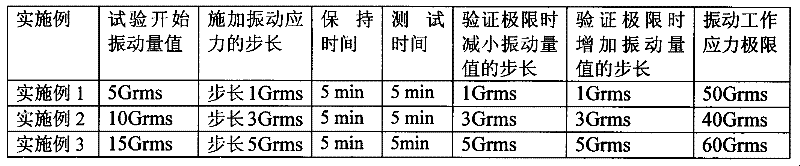

Embodiment 1

[0027] This embodiment is a test to determine the vibration working stress limit for the first type of control box, and the test sample is a set of control boxes. The test sample completed the design improvement for the vibration problem in the development test.

[0028] The test of this embodiment adopts a reliability enhancement test box of model UHS1200, a digital three-purpose meter, a signal source and an oscilloscope.

[0029] The specific process of this embodiment is:

[0030] Step 1. Determine the test parameters. The test parameters include the step starting point of the vibration test, the vibration step length, the vibration duration and performance test time at each step, the step length when verifying the vibration working stress limit, and the finally obtained vibration working stress limit. The starting point of the vibration test step in this embodiment is 5 Grms, the vibration step length is 1 Grms, and the smaller the step length is, the more accurate. The vibrat...

Embodiment 2

[0036] This embodiment is a test to determine the vibration working stress limit for the second type of control box, and the test sample is a set of control boxes. The test sample completed the design improvement for the vibration problem in the development test.

[0037] The test of this embodiment adopts a reliability enhancement test box of model UHS1200, a digital three-purpose meter, a signal source and an oscilloscope.

[0038] The specific process of this embodiment is:

[0039] Step 1. Determine the test parameters. The test parameters include the step starting point of the vibration test, the vibration step length, the vibration duration and performance test time at each step, the step length when verifying the vibration working stress limit, and the finally obtained vibration working stress limit. The vibration test step starting point of this embodiment is 10 Grms, the vibration step length is 3 Grms, and the smaller the step length, the more accurate, the vibration dura...

Embodiment 3

[0045] This embodiment is a test to determine the vibration working stress limit for the third type of control box, and the test sample is a set of control boxes. The test sample completed the design improvement for the vibration problem in the development test.

[0046] The test of this embodiment adopts a reliability enhancement test box of model UHS1200, a digital three-purpose meter, a signal source and an oscilloscope.

[0047] The specific process of this embodiment is:

[0048] Step 1. Determine the test parameters. The test parameters include the step starting point of the vibration test, the vibration step length, the vibration duration and performance test time at each step, the step length when verifying the vibration working stress limit, and the finally obtained vibration working stress limit. The vibration test step starting point of this embodiment is 15 Grms, the vibration step length is 5 Grms, and the smaller the step length is, the more accurate, the vibration du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com