Determination method for covering power of titanium dioxide

A measurement method, titanium dioxide technology, applied in the field of titanium dioxide production, can solve the problems of low accuracy and long time consumption, and achieve the effect of high accuracy of results, simple and easy operation, and fast and effective analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

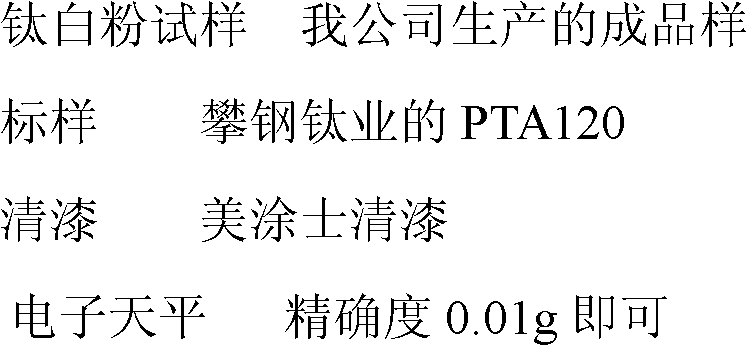

[0059] 1 Weigh 10g of Meitushi paint (packed in a drinking cup) on a coarse balance, then add 1g of a batch of samples produced by our company, and stir evenly with a glass rod for 5 minutes; the standard sample preparation method is the same;

[0060] 2 Place the prepared paint paste on a black and white cardboard whiteboard with a glass rod, place the standard sample on the left, and the sample on the right (the sample and the standard sample are basically parallel, and there is an interval of 3 mm), and then prepare it with a wet film scrape from the whiteboard to the blackboard;

[0061] 3 Place the cardboard horizontally in the room for 0.5h at room temperature;

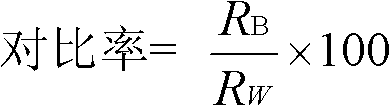

[0062] 4 First measure the reflectance of the coating film on the white board, measure four points up, down, left, and right, and calculate the average value R W ; Measure the coating film on the blackboard again, measure four points up and down, left and right, and calculate the average value R B The standard s...

Embodiment 2

[0065] Step is the same as embodiment 1, adopts two batches of samples produced by our company (different from the production time of a batch of samples), the selected standard sample is the same as the embodiment standard sample; test contrast ratio, test result is as shown in table 1 .

Embodiment 3

[0067] Step is the same as embodiment 1, adopts three batches of samples produced by our company (different from the production time of one batch and two batches of samples), the selected standard sample is the same as the embodiment standard sample; test contrast ratio, test result is as follows As shown in Table 1; if the contrast ratio of the sample is greater than the contrast ratio of the agreed standard sample, it indicates that the hiding power index of this batch of samples is qualified, otherwise it is unqualified.

[0068] In practical application, the inventor often combines the method of the present invention with a relatively accurate visual method to compare two kinds of titanium dioxide hiding powers. The visual method adopted is specifically: take by weighing 10g Metosil paint (with Drinking cup), then add 1g of a batch of samples produced by our company, stir evenly with a glass rod for 5 minutes, the standard sample preparation method is the same; use a glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com