Reliability test method for photovoltaic component

A technology of photovoltaic modules and test methods, which is applied in the monitoring of photovoltaic systems, single semiconductor device testing, photovoltaic modules, etc., can solve the problems of long cycle, only half the temperature rise and fall, and long test time, so as to speed up the test time and speed up the test. Promote and use, facilitate research and development, and test and evaluate the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

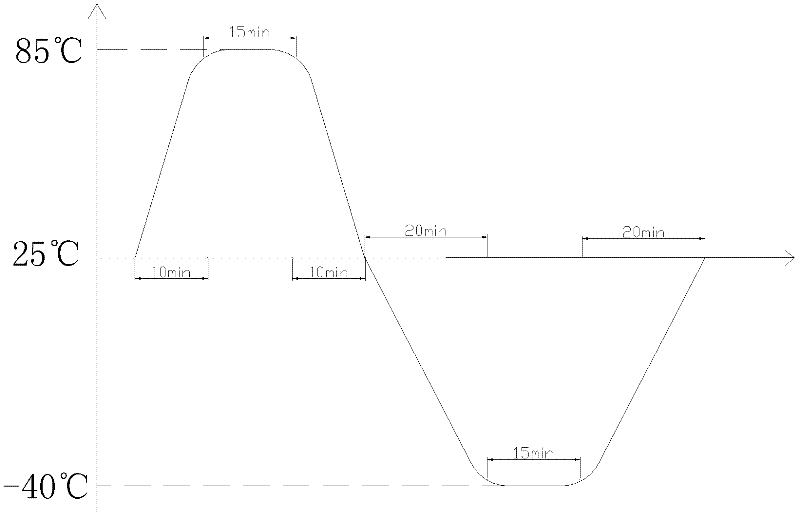

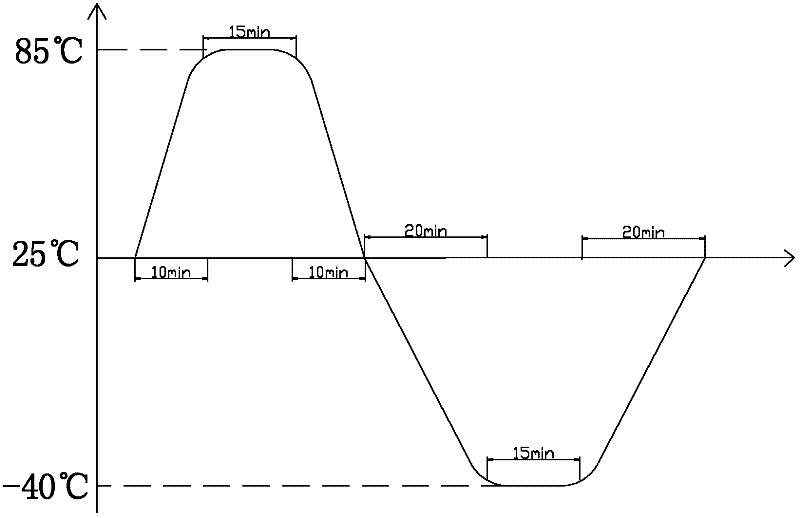

[0018] Such as figure 1 As shown, the specific process is as follows: 1. Raise the temperature of the photovoltaic module from +25°C to +85°C, and it takes 10 minutes; 2. Keep the temperature of the photovoltaic module at 85°C, and keep it warm for 15 minutes; It takes 30 minutes to drop from +85°C to -40°C; 4. When the temperature of the photovoltaic module is kept at -40°C, keep the temperature at low temperature for 15 minutes; 5. It takes time to raise the temperature of the photovoltaic module from -40°C to +25°C 20min; 6. Repeat the process from 1 to 5 100 times.

[0019] exist figure 1 On the basis of , it takes a total of 90 minutes to realize a thermal cycle, 100 cycles are equivalent to 200 conventional thermal cycles, and 200 cycles are equivalent to 500 conventional thermal cycles.

Embodiment 2

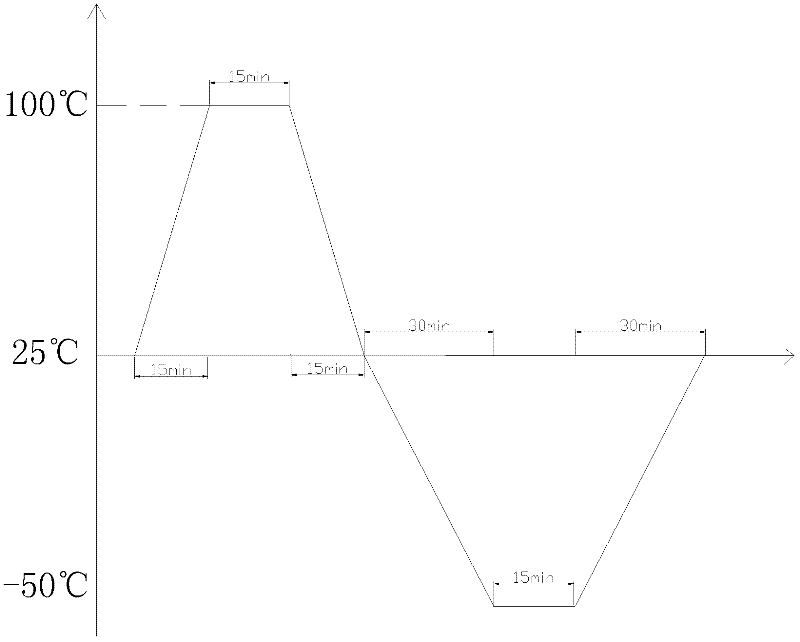

[0021] Such as figure 2 As shown, the process is as follows: 1. Raise the temperature of the photovoltaic module from +25°C to +100°C, which takes 15 minutes; 2. Keep the temperature of the photovoltaic module at 100°C, and keep it warm for 15 minutes; 3. Increase the temperature of the photovoltaic module from It takes 45 minutes to drop from +100°C to -50°C; 4. Keep the temperature of the photovoltaic module at -50°C, and keep it at low temperature for 15 minutes; 5. It takes 20 minutes to increase the temperature of the photovoltaic module from -50°C to +25°C. 6. Repeat the process from 1 to 5 60 times.

[0022] exist figure 2 On the basis of , it takes a total of 120 minutes to realize a thermal cycle, and 60 cycles are equivalent to 500 conventional thermal cycles.

[0023] Taking the tin-coated copper strip of photovoltaic modules as an example, by making small components connected in series with 4pcs cells and a separate tin-coated copper strip, tests and comparison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com