Welding spot defect identifying method

A solder joint and defect technology, applied in the field of microelectronic packaging and assembly, can solve problems such as easy to fall into local optimal solution, slow convergence of neural network, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the accompanying drawings.

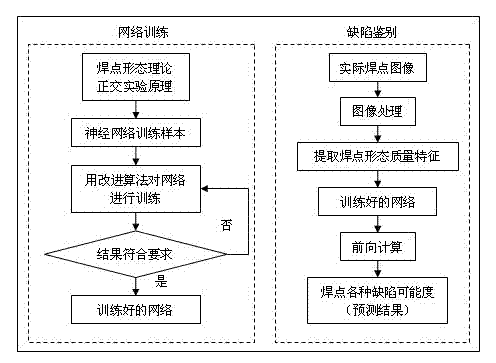

[0062] See figure 1 . The invention is divided into two parts: network training and defect identification.

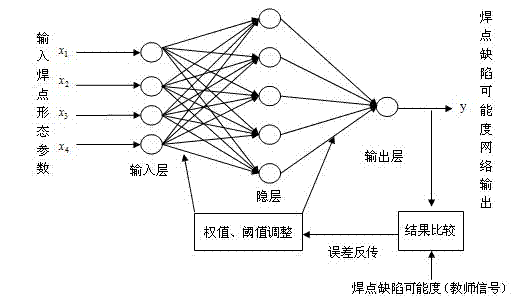

[0063] The network training includes 1), based on the shape theory of solder joints, and according to the principle of orthogonal experiment, to obtain the samples used for training the artificial neural network; 2), to train the artificial neural network with the improved neural network algorithm, and to obtain A network of various defect possibilities for solder joints. Defect identification includes image processing of actual solder joints, extracting morphological quality features as the input of the trained artificial neural network, and using the trained network for forward calculation to realize the identification of solder joint defects.

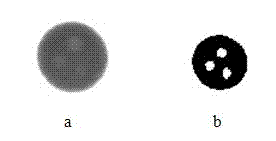

[0064] Taking BGA solder joints with a solder ball diameter of 0.75mm and a solder ball pitch of 1.27mm as an examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com