Dynamic adjustment method for infrared temperature measuring period of transformer station equipment

An infrared temperature measurement and dynamic adjustment technology, applied in the field of power systems, can solve the problems of missing the best period to prevent failures, relying on regular periodic inspections, and adjusting the inspection cycle, so as to promote informatization, realize automation and intelligence, The effect of liberating productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

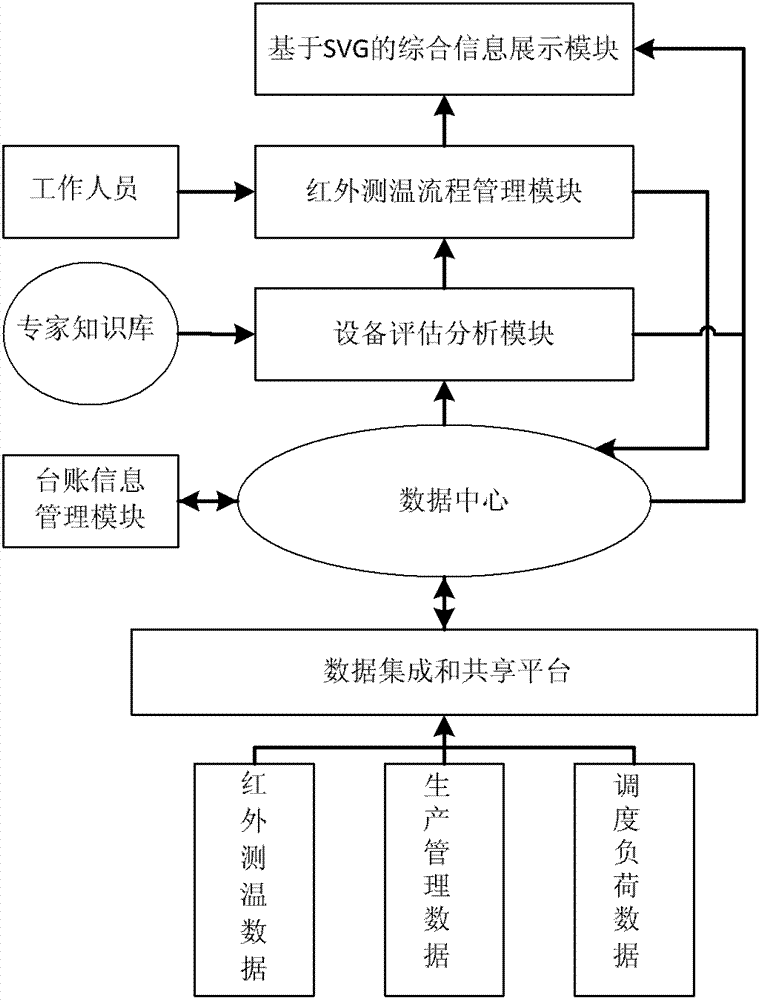

[0063]The purpose of this invention is to provide a new method, through the implementation of this method, the production and operation personnel can adjust the infrared temperature measurement cycle in time according to the dispatching load information of the power grid and the infrared temperature measurement information, and in the optimal period, the hidden dangers of electric power and heat Effective monitoring and prevention of thermal faults can reduce the risk of grid operation and improve the stability and safety of grid operation.

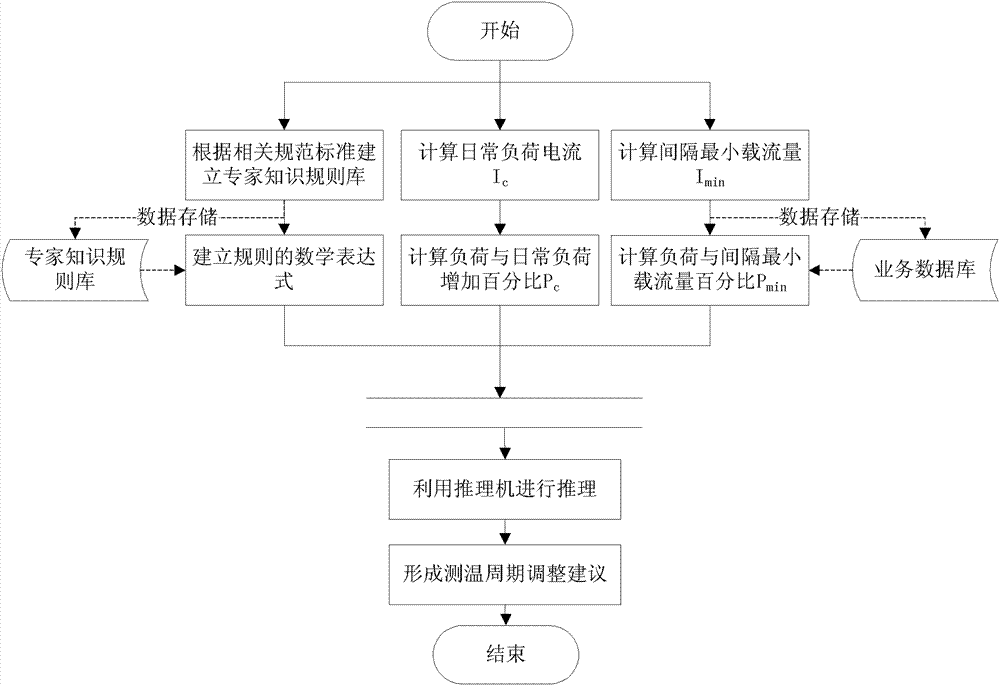

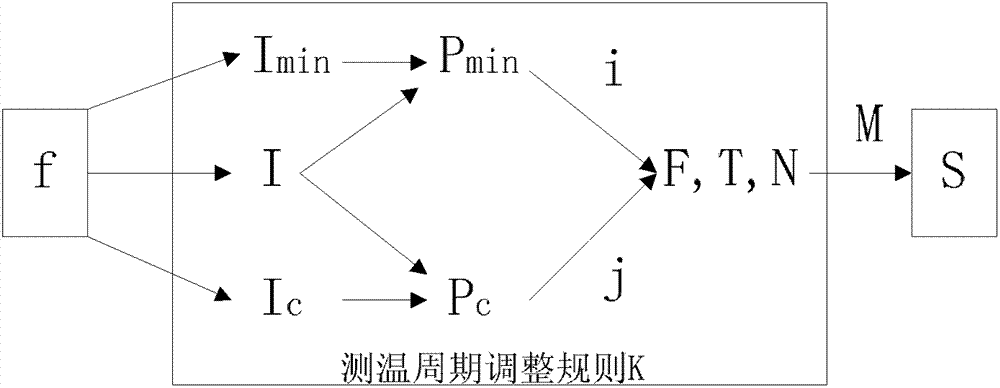

[0064] A method for dynamically adjusting the infrared temperature measurement cycle of substation equipment proposed by the present invention mainly includes the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com