Dynamic gas well productivity forecasting method

A productivity forecasting and dynamic technology, applied in forecasting, instrumentation, data processing applications, etc., can solve the problems of increased development and testing costs, affecting gas well production, etc., and achieve the effects of saving manpower, great practical value and economic value, and accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

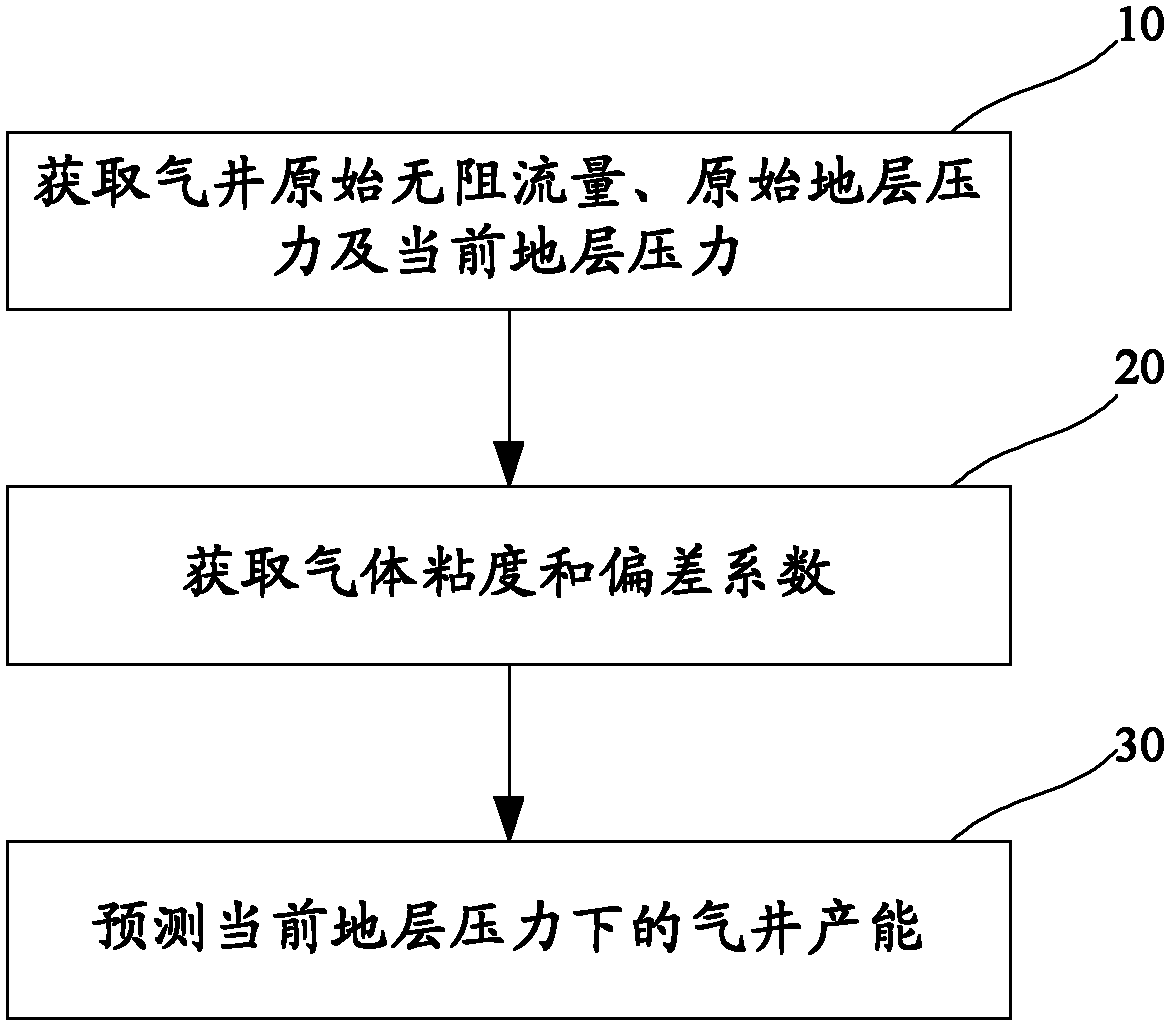

[0016] see figure 1 , a gas well dynamic productivity prediction method provided by an embodiment of the present invention, comprising:

[0017] Step 1. Obtain the original open flow q of the gas well AOFi , original formation pressure p i and current formation pressure p m . Among them, the original open flow rate of the gas well q AOFi , original formation pressure p i It is tested before gas well production. The current formation pressure can be obtained by pressure gauge.

[0018] Step 2. Obtain the gas viscosity μ g and the coefficient of deviation Z.

[0019] natural gas viscosity μ g = 10 - 4 Kexp ( X ρ g Y ) , in,

[0020] K = 2.6832 × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com