Annular array thermoelectric generator with functional gradient thermoelectric arms

A technology of thermoelectric generators and functional gradients, applied in the direction of generators/motors, electrical components, etc., can solve the problems of lack of research on the comprehensive design and application of thermoelectric generators, and the lack of research reports on thermoelectric generators, so as to improve the output power and work efficiency, easy installation, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

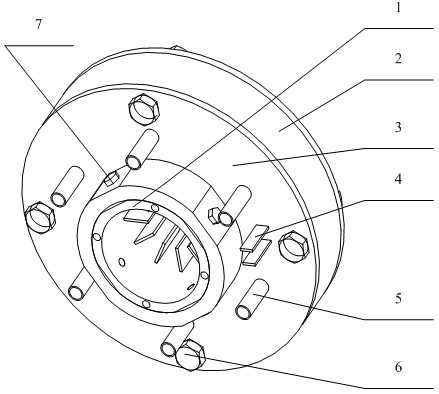

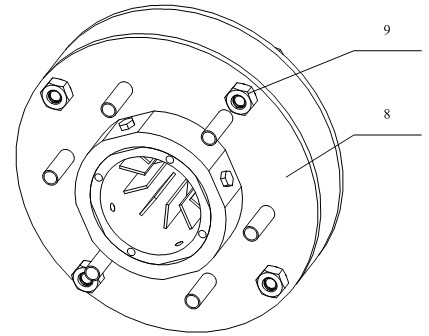

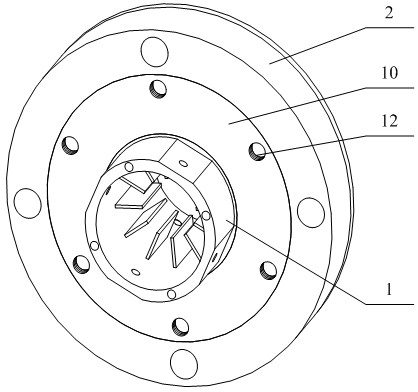

[0028] Such as Figure 1 to Figure 12 As shown, the present invention includes a high-temperature end heat exchanger 1, a low-temperature end heat exchanger 2, a first sleeve 8, a second sleeve 3, a plurality of P-type thermoelectric arms 13, and the same number of P-type thermoelectric arms 13 N-type thermoelectric arm 14, the first sealing ring 12, the second sealing ring 10, the third sealing ring 12 and the fourth sealing ring 10; as Figure 7 , the middle part of the cylinder of the high-temperature end heat exchanger 1 is provided with a plurality of fins 22 symmetrically and equally distributed with both ends, and the cylinder opposite to the fins 22 is provided with a plurality of equally distributed heat transfer arms 19, The outer ends of the cylinder without fins 22 are respectively provided with equally distributed threaded holes 20 for fixing, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com