Biogas slurry reduction treatment and biogas collaborative purification system and purification method

A purification system and reduction technology, applied in chemical instruments and methods, separation methods, water/sewage multi-stage treatment, etc., can solve the problems of large volume, low utilization rate and low fertilizer efficiency, and achieve low temperature requirements and reduced The equipment covers an area and the effect of enhancing fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

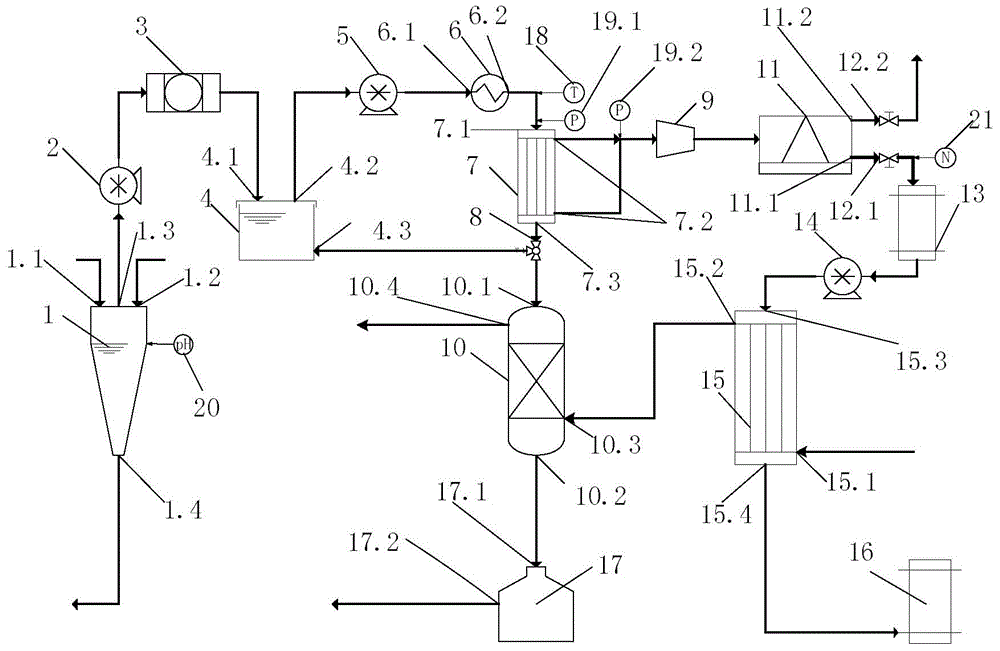

[0036] like figure 1 The shown biogas slurry reduction treatment and biogas collaborative purification system and purification method include a biogas slurry mixing and stirring tank 1, a centrifugal pump 2, a security filter 3, a fine filtration biogas slurry storage tank 4, a fine filtration biogas slurry pump 5, Heater 6, hollow fiber membrane contactor 7, vacuum pump 9, washing and purification tower 10, condenser 11, ammonia water storage tank 13, ammonia water pump 14, ammonia water rich liquid storage tank 16, desulfurization and decarbonization tower 15, biogas liquid rich liquid storage tank The liquid tank 17 also includes a three-way valve 8, a first valve 12.1, and a second valve 12.2. The biogas slurry mixing and stirring tank 1 is provided with a biogas slurry inlet 1.1 and a plant ash inlet 1.2. The input of the centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com