Method for accurately controlling water content in tobacco processing

An accurate and moisture technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of insufficient correction and achieve the effects of reducing moisture content fluctuations, improving stability and accuracy, and improving moisture control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

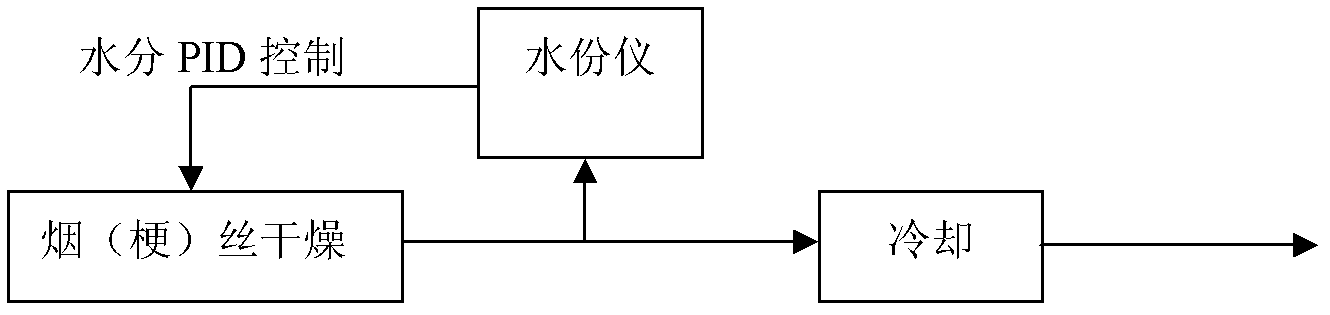

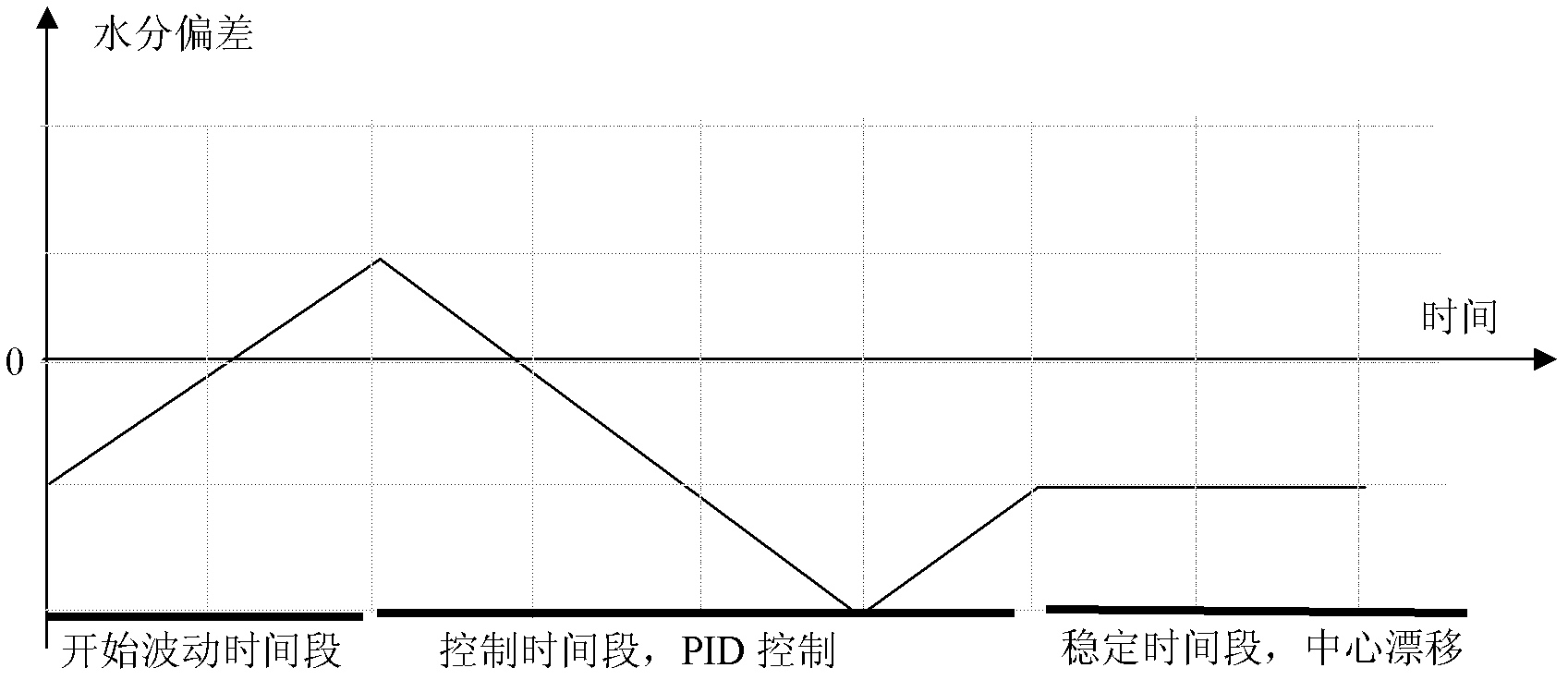

[0027] An application example of the method for accurately controlling moisture of the present invention in the drying link of shredded leaves and shredded stems of a silk thread. Such as Figure 8 As shown, the first moisture meter is set at the outlet of the silk dryer, and the second moisture meter is set at the outlet of the cooler. Due to the good accuracy of the moisture value detected at the outlet of the cooler, the detected moisture value is input into the control computer, and the moisture value required by the standard after cooling is calculated by PID to calculate the correction value, which forms the standard value of moisture at the outlet of the dried silk , compared with the moisture value at the outlet of the dried silk detected by the first moisture meter, and based on the comparison results, the PID calculation and control of the silk dryer is performed. Running effect analysis such as Figure 9 .

[0028] According to the actual operation effect, after ...

Embodiment 2

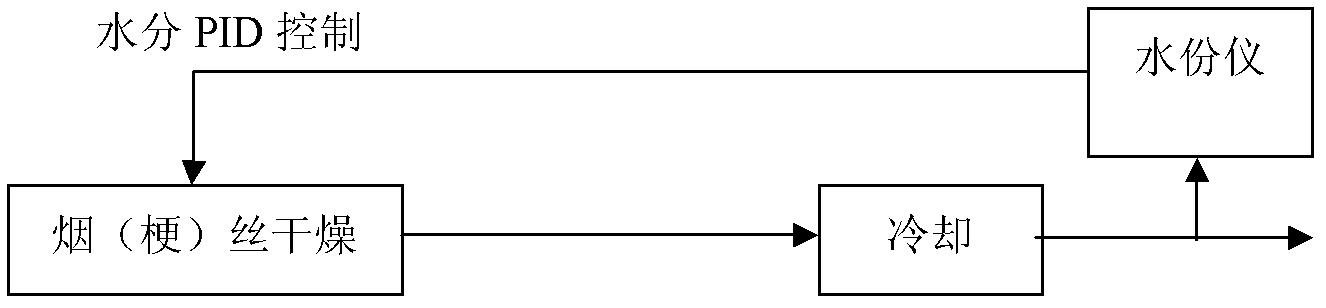

[0030] An application example of the method for accurately controlling moisture of the present invention in the leaf redrying link of a threshing and redrying line. Such as Figure 10 As shown, the first moisture meter is set at the outlet of the leaf roaster, and the second moisture meter is set at the outlet of the baler. Due to the good accuracy of the moisture value detected at the outlet of the baler, the detected moisture value is input into the control computer, and the moisture value required by the standard after packaging is calculated by PID to calculate the correction value, which forms the standard value of moisture at the outlet of the baking machine , and compare it with the moisture value at the outlet of the oven detected by the first moisture meter, and perform PID calculation and control on the oven machine according to the comparison result. Running effect analysis such as Figure 11 .

[0031] According to the actual operation effect, after using the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com