High temperature methanation device

A methanation and high-temperature technology, applied in organic chemistry, hydrocarbon production from carbon oxides, chemical instruments and methods, etc., can solve the problems of strict requirements for pipeline materials and connection structures, overheating of by-products, large equipment footprint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

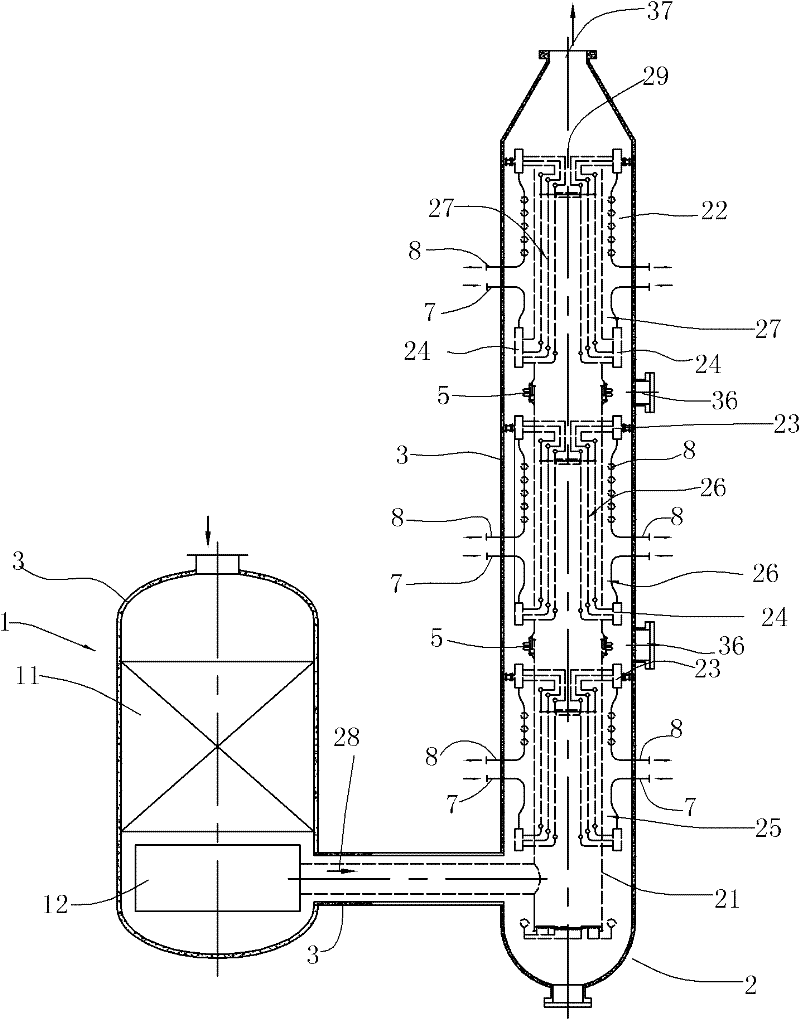

[0019] like Figure 1 to Figure 6 As shown, the high temperature methanation unit includes:

[0020] The methane reactor 1 mainly includes two parts, namely a catalyst layer 11 and a gas collector 12 arranged below the catalyst layer 11 . The methanation reactor in this embodiment is a vertical cylindrical vessel, the shell wall is covered with refractory and heat-insulating lining, and the middle part is filled with catalyst. The structure of the methane reactor is prior art.

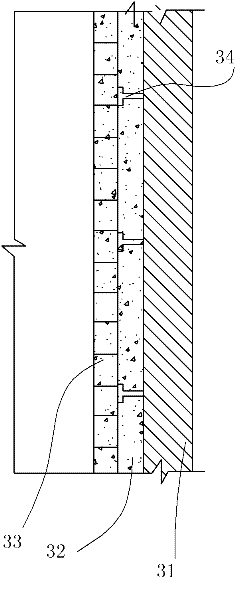

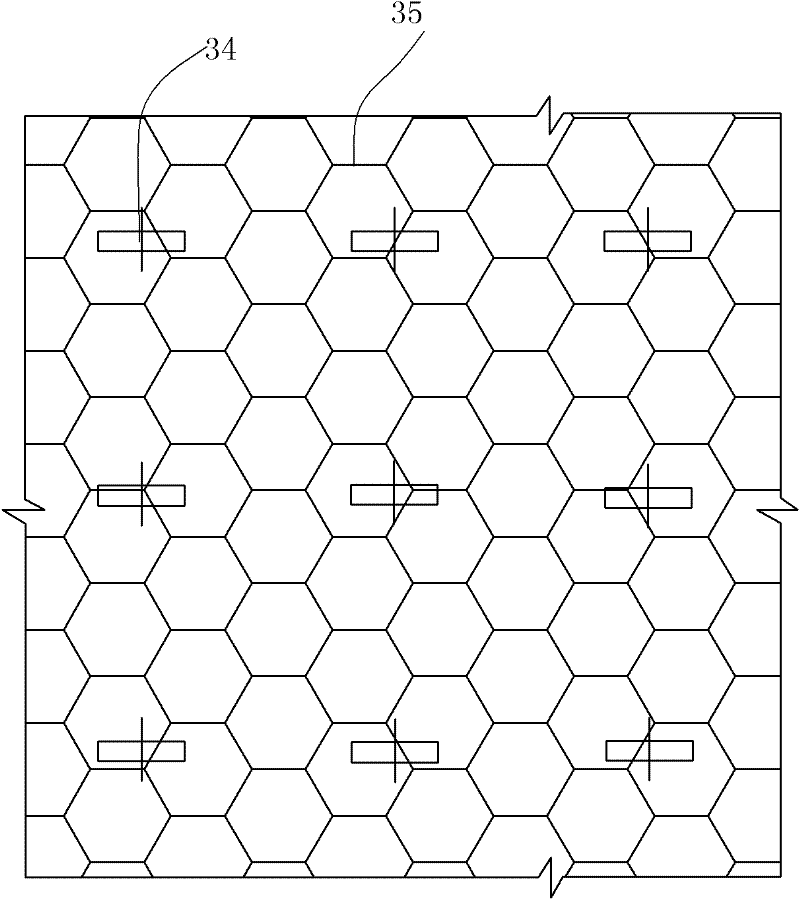

[0021] The heat exchanger 2 is a vertical structure with three sections. Each section of the heat exchanger in this embodiment adopts a membrane-type water-cooled wall structure, which includes a cylinder 21 for the passage of the heat medium, that is, the process gas. Each layer of water-cooled walls in the cylinder body 21 and an upper header 23 and a lower header...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com