Hot leveler roll cassettes where backup rolls can be mounted individually and directly

A back-up roll, hot straightening technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of high center deviation, failure of assembly accuracy, inconvenient disassembly, etc., to improve adverse deformation effects, maintain Assembly accuracy, the effect of facilitating maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

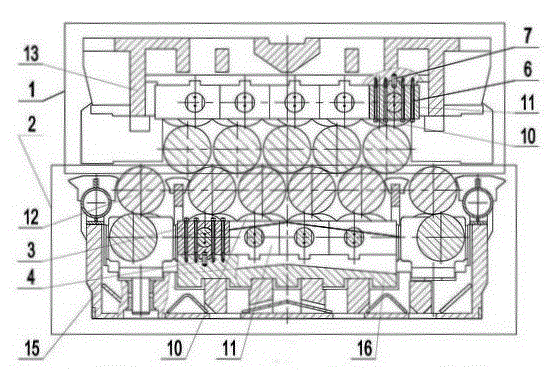

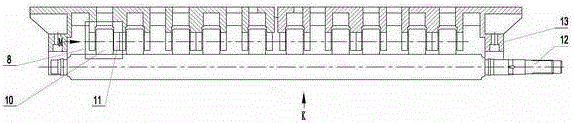

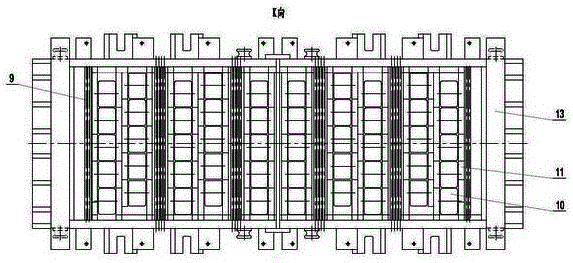

[0031] The straightener roll box of the present invention is divided into upper and lower parts. When the invention is installed, the interface size is consistent with the existing technology, the center height of the straightening roller remains unchanged, and can be interchanged with the existing roller box. The key difference lies in the structural form and installation method of the backup roller.

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown, each supporting roller group-8 of last roller box-1 all is on the front of roller box (roller box assembly is that upper base-13 is turned over and roller is carried out upwards), each supporting roller group-1 8 are all directly installed on the upper base one 13 of the band groove notch, and each supporting roller group one 8 is fastened on the upper base one 13 by screw two 6, and the supporting roller group one 8 passes through the support plate 11 by the upper base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com